Ultra-micro micro-beam-tube type optical cable

An ultra-miniature, tube-type technology, applied in the field of communication optical cables, can solve the problems of inability to achieve ultra-miniature optical cables, low tensile performance of optical cables, and excessively large outer diameter of optical cables, and achieve high tensile performance and excellent attenuation transmission Performance and temperature performance, space resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

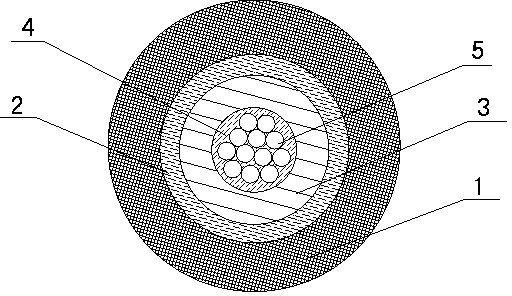

[0019] Such as figure 1 Shown, a kind of ultra-miniature micro-bundle tube type optical cable, it comprises the optical fiber bundle 5 that one or more optical fibers are formed, loose tube 3, strengthens filling layer 2 and outer sheath 1, and described optical fiber bundle 5 is positioned at loose Fiber paste 4 is filled inside the tube 3 and between the fiber bundles inside the loose tube 3 , and the outer side of the loose tube 3 is wrapped by a reinforced filling layer 2 , and the outermost layer of the reinforced filling layer 2 is an outer sheath 1 .

[0020] The number of optical fibers contained in the optical fiber bundle 5 is 2-12, and the number of optical fibers can be adjusted according to actual conditions.

[0021] The rein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com