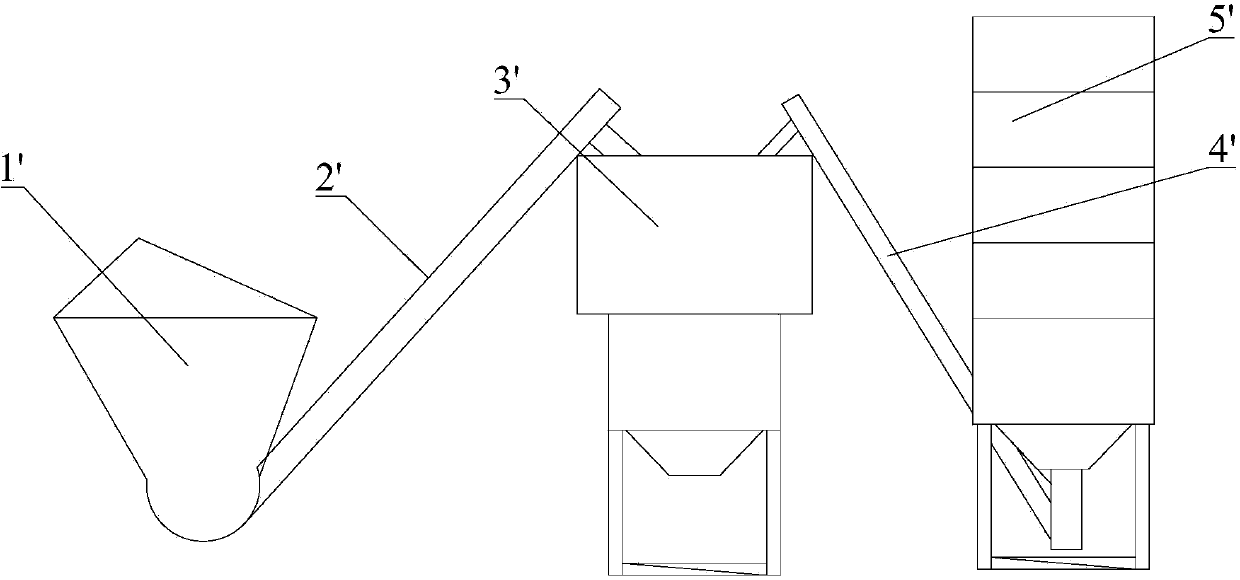

Mortar mixing station and control system thereof

A mortar mixing and control system technology, applied in the field of ready-mixed mortar, can solve the problems of large scale of mixing building 3', influence on integration, and reduction of available space of mixing building 3', so as to facilitate movement, improve integration and reduce space size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be pointed out that the description of specific structures and the order of description in this section are only descriptions of specific embodiments, and should not be regarded as limiting the protection scope of the present invention. In addition, the embodiments in this part and the features in the embodiments can be combined with each other if there is no conflict.

[0031] Please also refer to figure 2 , image 3 with Figure 4 In the following, the embodiments of the present invention will be described in detail with reference to the accompanying drawings.

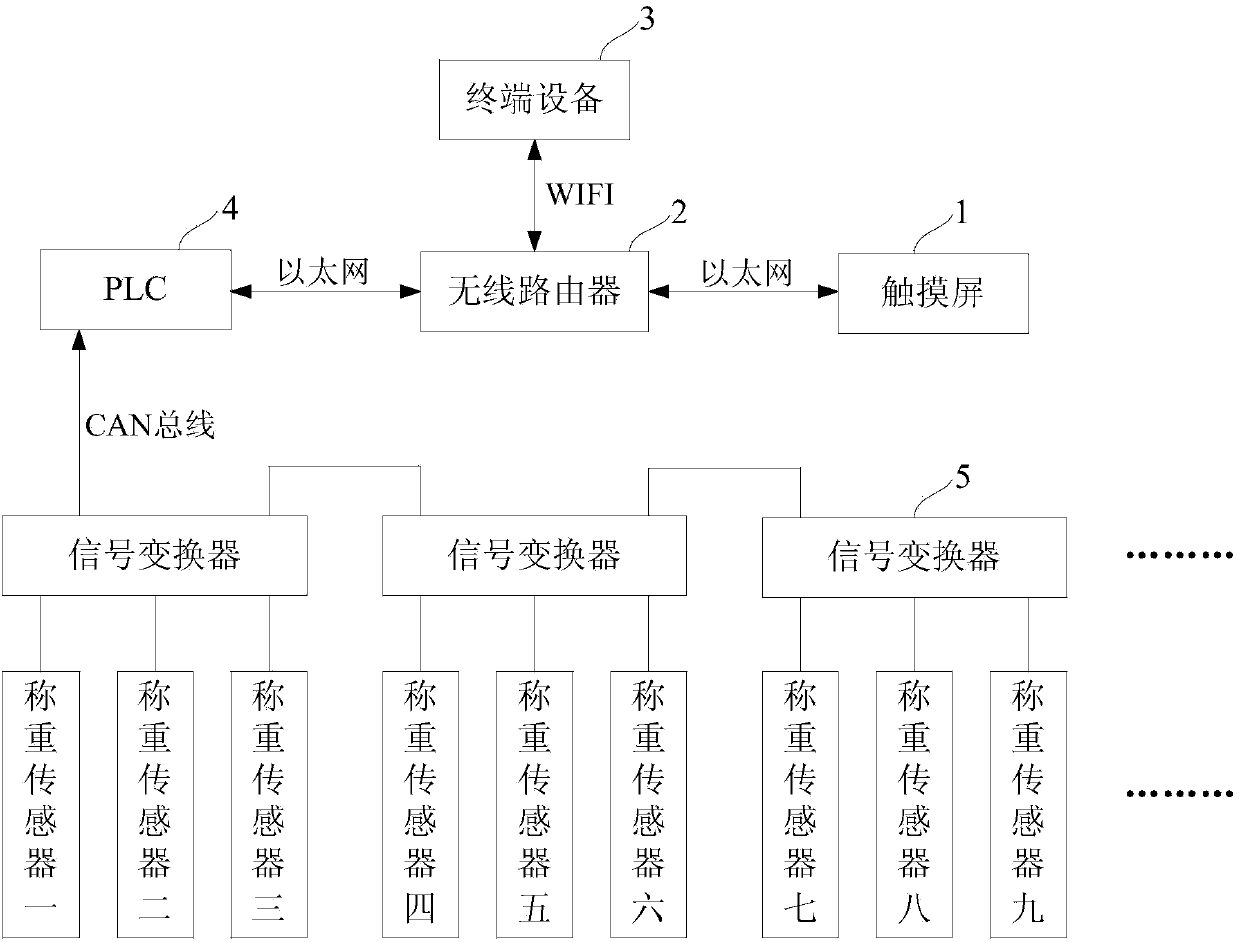

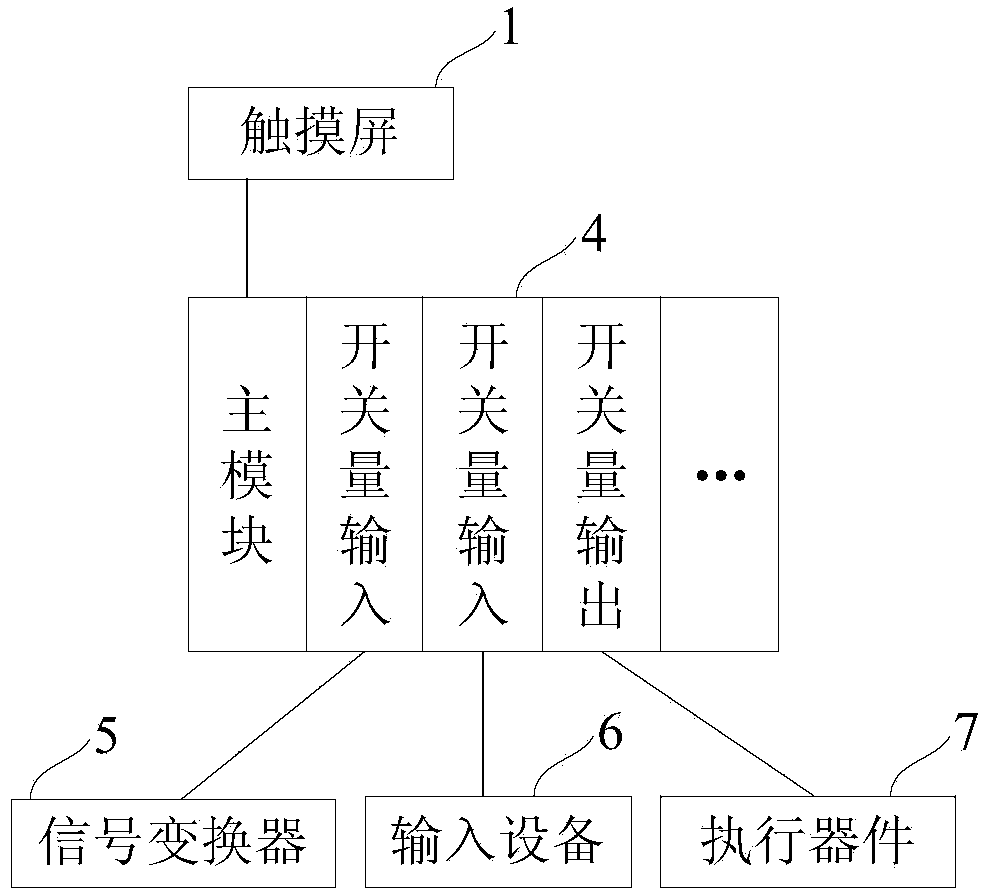

[0032] Combine figure 2 As shown, the mortar mixing plant control system of this embodiment may include a touch screen 1, a wireless router 2, a terminal device 3, a programmable logic controller 4 (hereinafter referred to as PLC), a plurality of signal converters 5 and a plurality of load cells.

[0033] Among them, the touch screen 1 communicates with the wireless router 2 through Ethernet, the termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com