Control system of optical touch screen

An optical touch screen and control system technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of complex control methods and high clock accuracy requirements, avoid high light effects, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

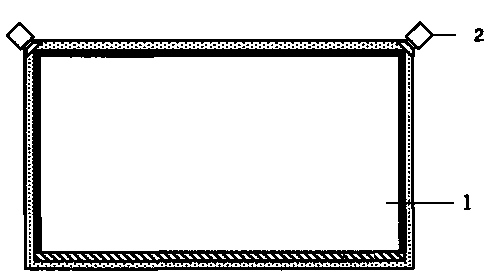

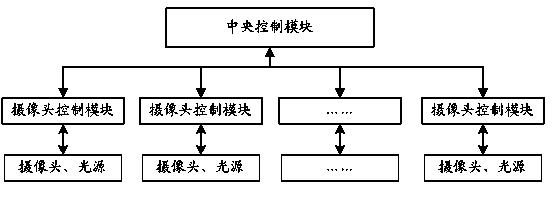

[0043] This embodiment provides a control system for an optical touch screen, such as figure 2 As shown, it includes: a central control module; at least two groups of camera control modules, each group of camera control modules includes at least one camera control module, and each of the camera control modules is used to control the opening or closing of a camera; the central The control module sends control instructions to all camera control modules in each group at different times; different camera control modules control the corresponding cameras to work after receiving the control instructions.

[0044] With the solution of this embodiment, it is only necessary for the central control module to issue control commands at different times, so an accurate clock signal is not required in the central control module, and it is only necessary to be able to distinguish between different camera control modules A logical clock that controls time is sufficient. For example, if an ed...

Embodiment 2

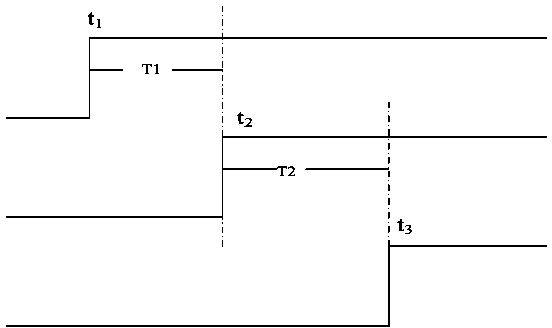

[0055] On the basis of Example 1, such as Image 6 As shown, each camera control module in this embodiment includes a synchronization control unit, a camera controller, a memory and an image processing unit. The synchronization control unit is configured to reset its corresponding camera after receiving the control instruction sent by the central control module. The camera controller is used to receive the image data output by the camera; the memory is used to store the image data received by the camera controller; the image processing unit is used to read the image data from the memory and Send the image data to the central control module after processing.

[0056] For the optical touch screen, the camera will output image data at a fixed frame rate after startup, and the camera will reset after receiving the reset command from the synchronization control unit, and the behavior after startup can be implemented after a fixed time. Therefore, for different cameras in the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com