Broadband full-sealed package of microwave devices

A microwave device, fully sealed technology, applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device parts, etc., can solve the problems of reducing thermal impedance, high thermal impedance, and fully-sealed packaging cannot work, etc., to achieve good impedance Matching, reducing the effect of coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

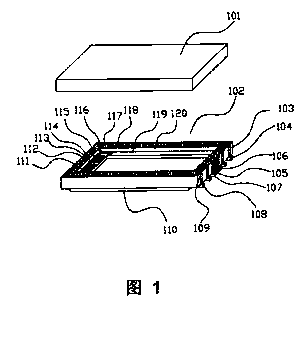

[0022] figure 1 For package perspective view. The entire package includes a cover 101 and a package body 102 . The package body 102 includes a ceramic frame 103 , a metal base 110 and a plurality of metal pins 104 .

[0023] The ceramic frame 103 is composed of multilayer ceramics. It can be made of high temperature co-fired ceramic (HTCC) or low temperature co-fired ceramic (LTCC) process, the HTCC process is more robust. In the production process, when the ceramics are still in the state of cement, the metal wires are printed on each layer of the substrate, and via holes are made to fill the metal material in the state of cement. Then put the first layer (lower layer) ceramics 119 and the second layer (upper layer) ceramics 120 together into the furnace for firing. These two layers of ceramics will become an integrated ceramic frame 103 . The metal base 110 and the metal pins 104 are respectively welded to the ground plane and the pad on the bottom surface of the cerami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com