Direct-current permanent-magnet planar motion platform

A motion platform and permanent magnet plane technology, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of complex structure of the motion platform, unsuitable volume and weight, etc., so as to reduce production cost and assembly difficulty, load Lightweight, the effect of improving movement precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

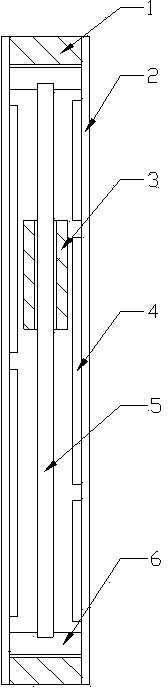

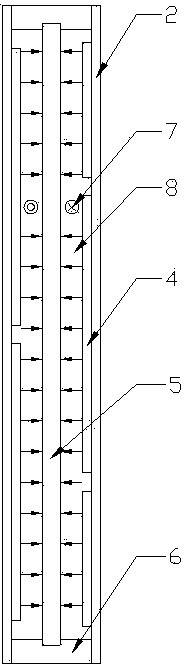

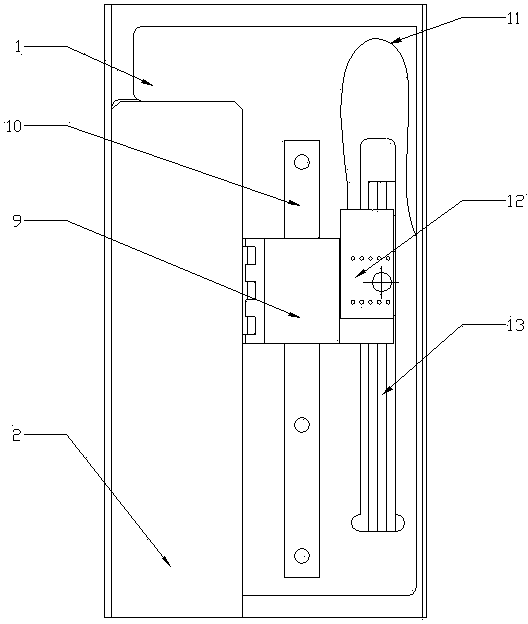

[0007] combine figure 1 as well as figure 2 Describe the implementation of the single linear module mover force. In this embodiment, it consists of a base 1, a permanent magnet stator, and a mover coil 3; the permanent magnet stator consists of an outer yoke 2, a permanent magnet array 4, an inner yoke 5, The side yoke 6 is composed; the permanent magnet array 4 is pasted on the outer yoke 2, and the outer yoke 2 is connected to the inner yoke 5 through the side yoke 6, thereby forming a complete magnetic field loop; The permanent magnet array 4 forms a uniform magnetic field 8 whose direction is perpendicular to the inner magnetic yoke 5 on its outer side; in the primary coil 3, the single-turn coil 7 penetrates the uniform magnetic field 8, bypasses the inner magnetic yoke 5, and passes through the inner magnetic yoke 5 from the other side. A uniform magnetic field passes through. When there is a positive current in the single-turn coil 7, the coil moves upwards under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com