Robot transmission with pressure compensation device

A technology of transmission and balancing device, which is applied to transmission parts, manipulators, manufacturing tools, etc., can solve the problem of transmission oil polluting the surrounding environment, and achieve the effect of preventing leaks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

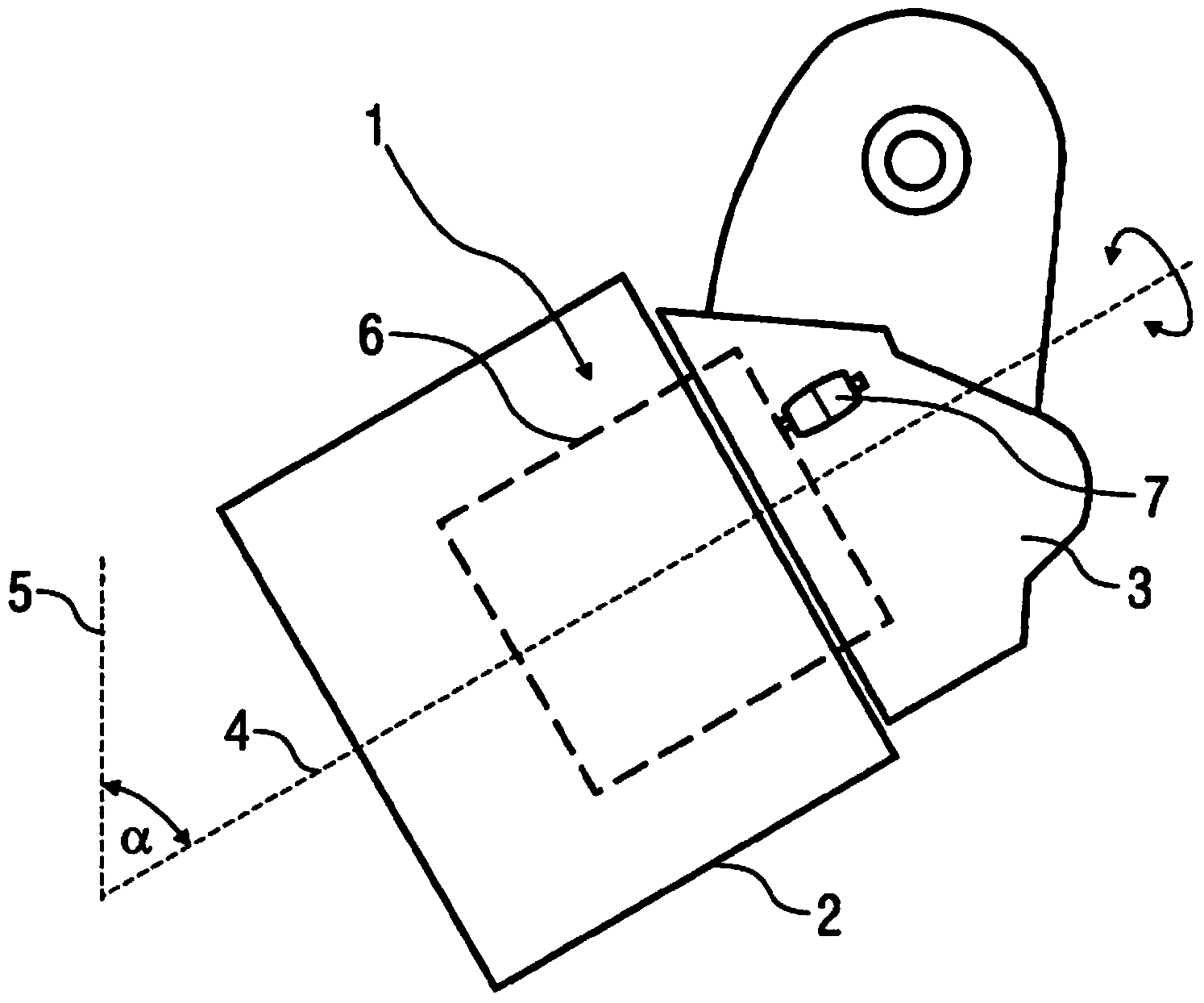

[0040] figure 1 A schematic diagram of a robot drive 1 between two axes 2, 3 of a multi-axis robot that can be used, for example, as a painting robot or Used as a handling robot. In this case, the robot transmission 1 enables a rotation of the shaft 3 relative to the shaft 2 about an axis of rotation 4 .

[0041] The axis of rotation 4 is in this case angled at an angle α relative to the vertical line 5 in order to show that different spatial orientations of the robot transmission 1 can be achieved during operation, which for the robot transmission The lubrication of 1 is meaningful, as will be explained in more detail.

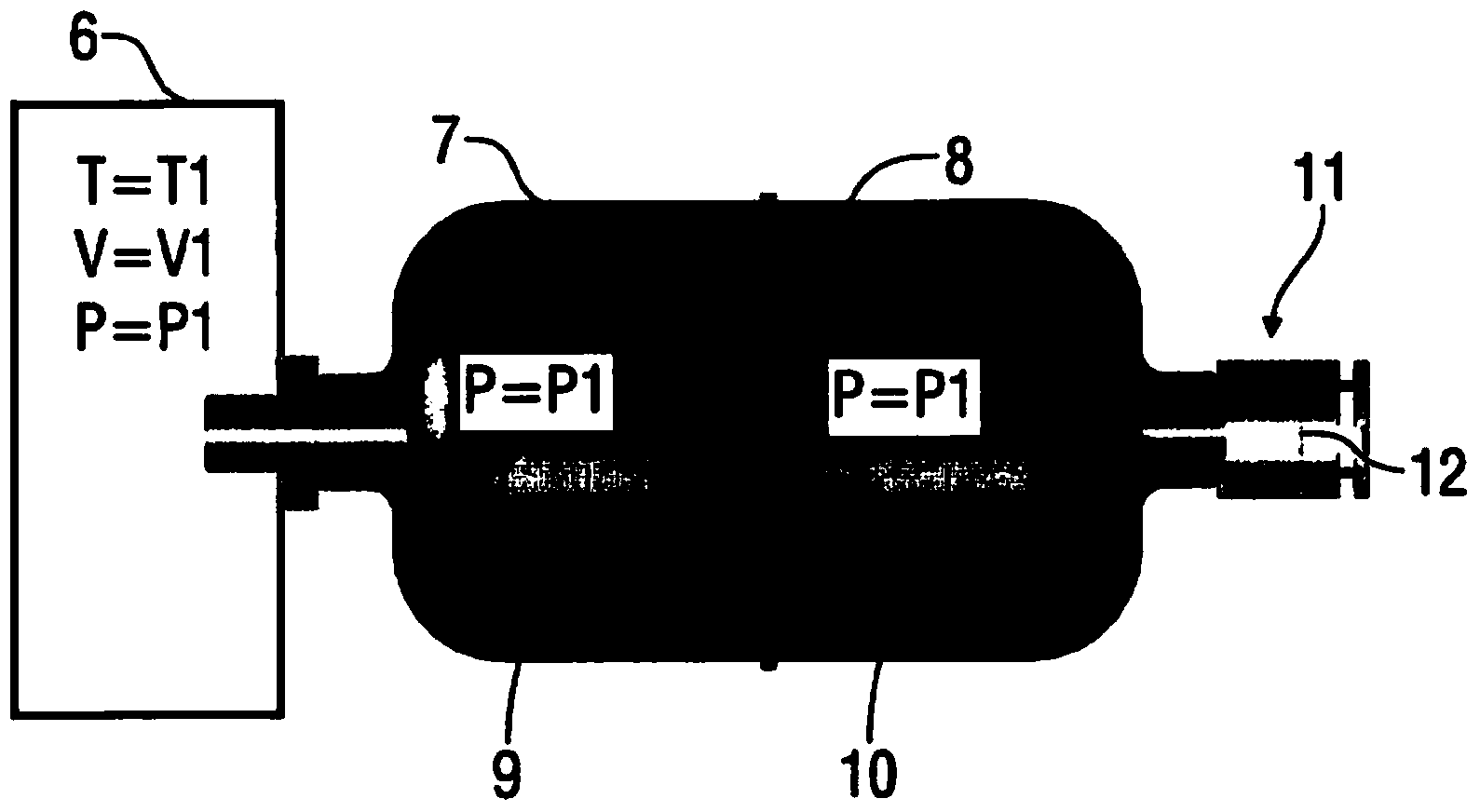

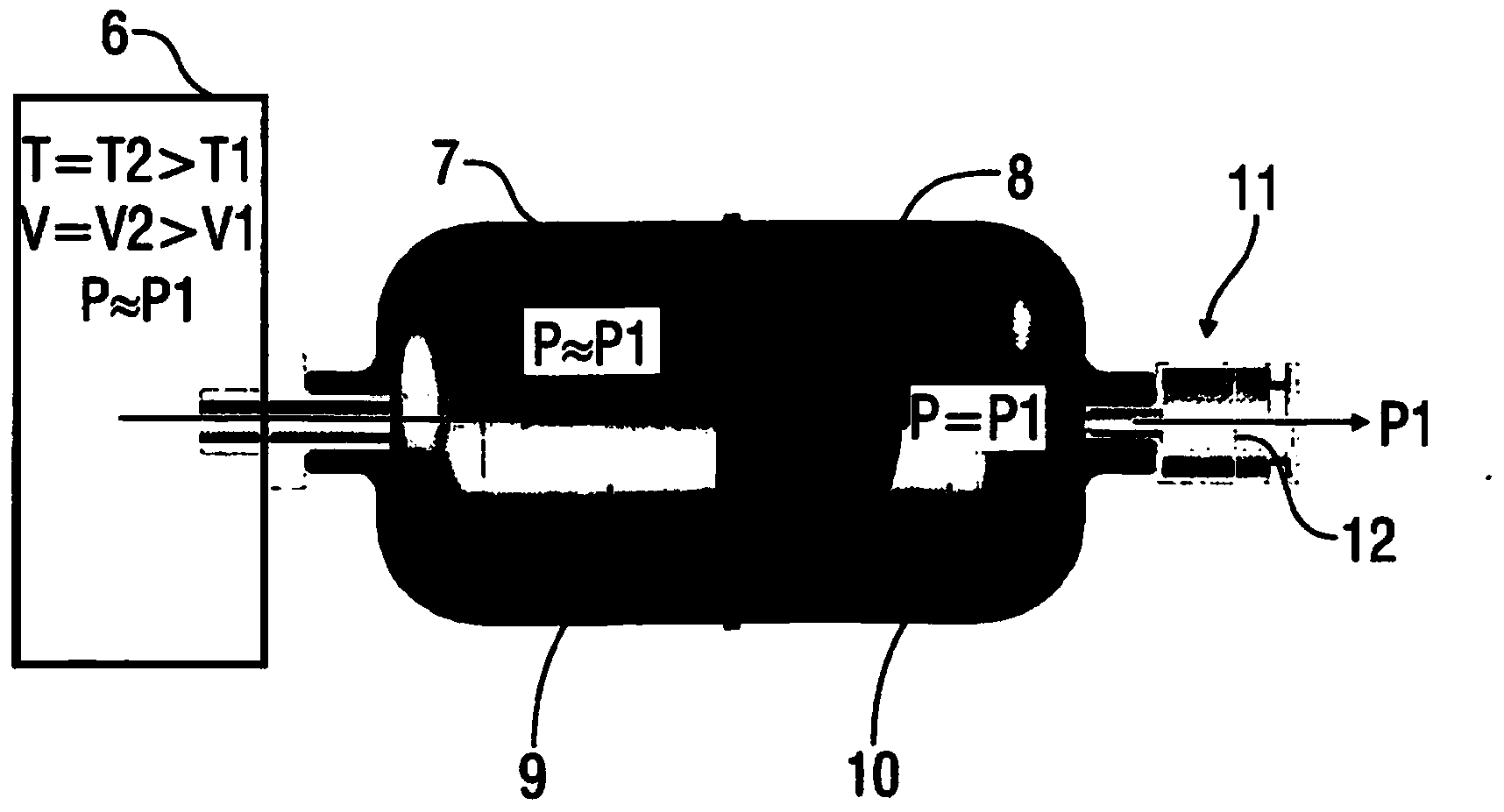

[0042] The robot transmission 1 has a transmission housing 6 indicated by dashed lines, which is completely filled with transmission oil during operation. During operation, however, friction-induced heat is generated in the robot transmission 1 , which leads to heating of the transmission oil and to a corresponding expansion of the transmission oil. Howev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com