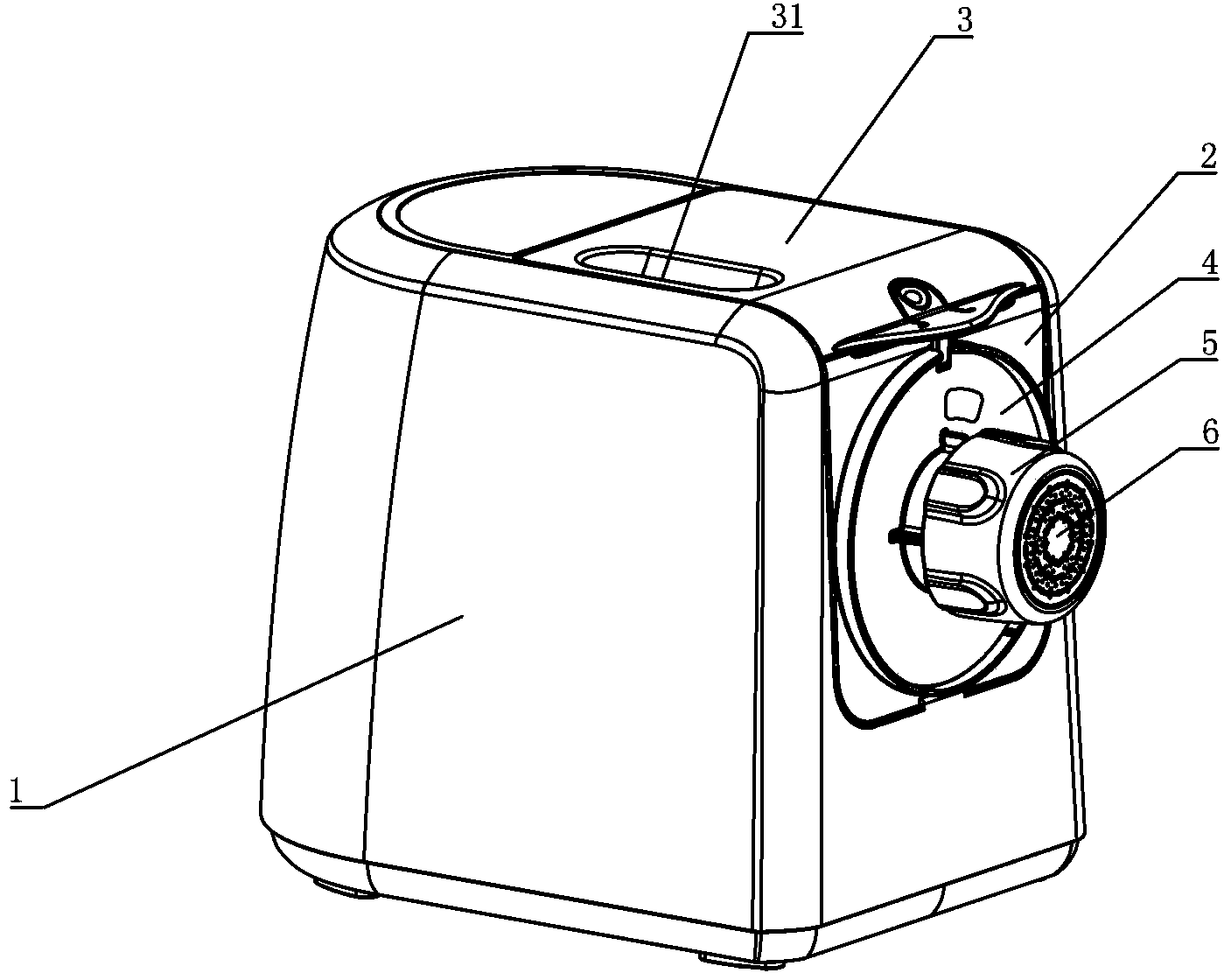

Noodle maker extruding safely

A noodle machine and safe operation technology, applied in the field of food processing, can solve the problems of cracking and damage of the extruding cylinder, user injury, etc., and achieve the effects of facilitating the extruding process, improving the stiffness, and preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

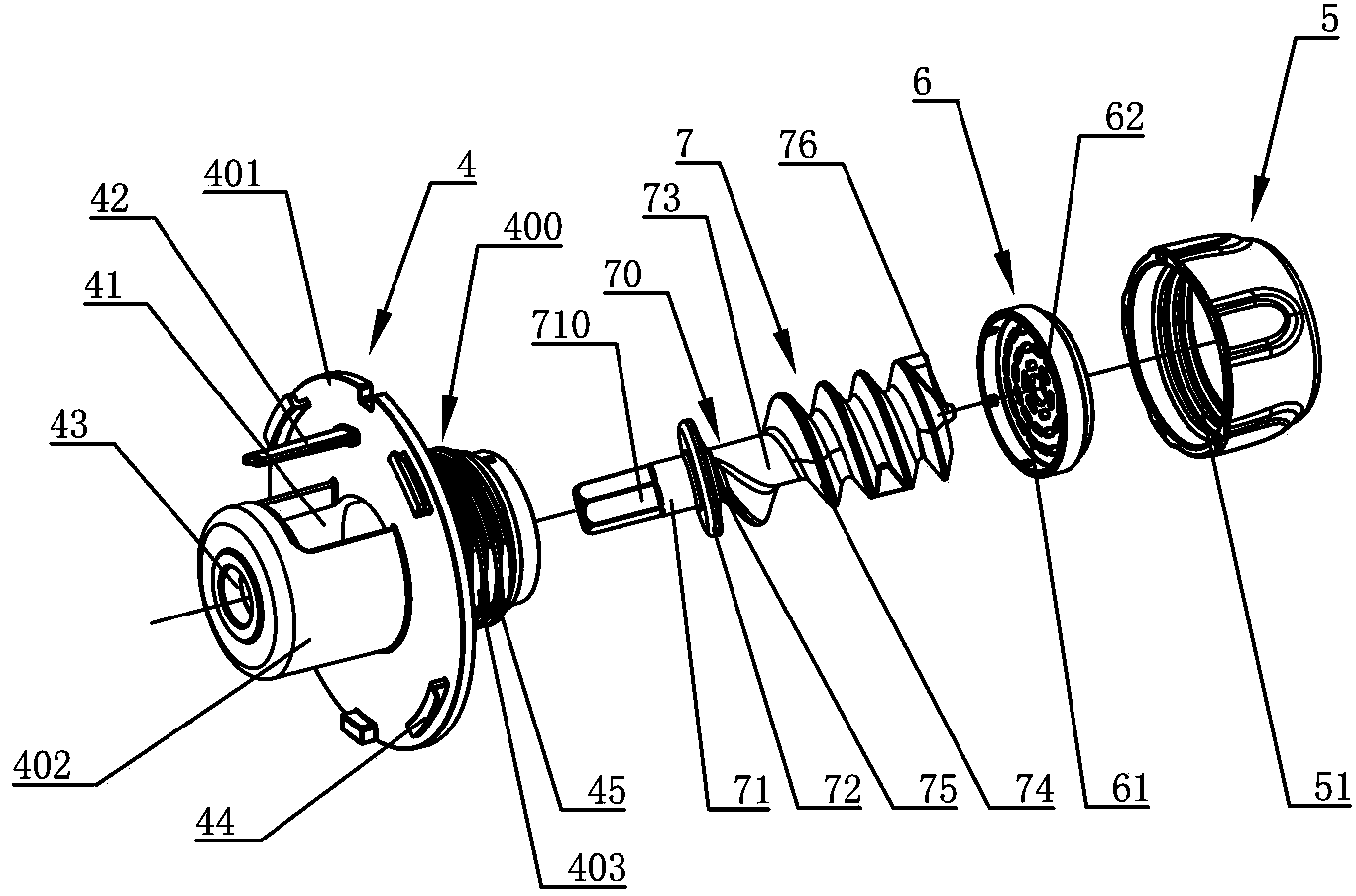

Embodiment 1

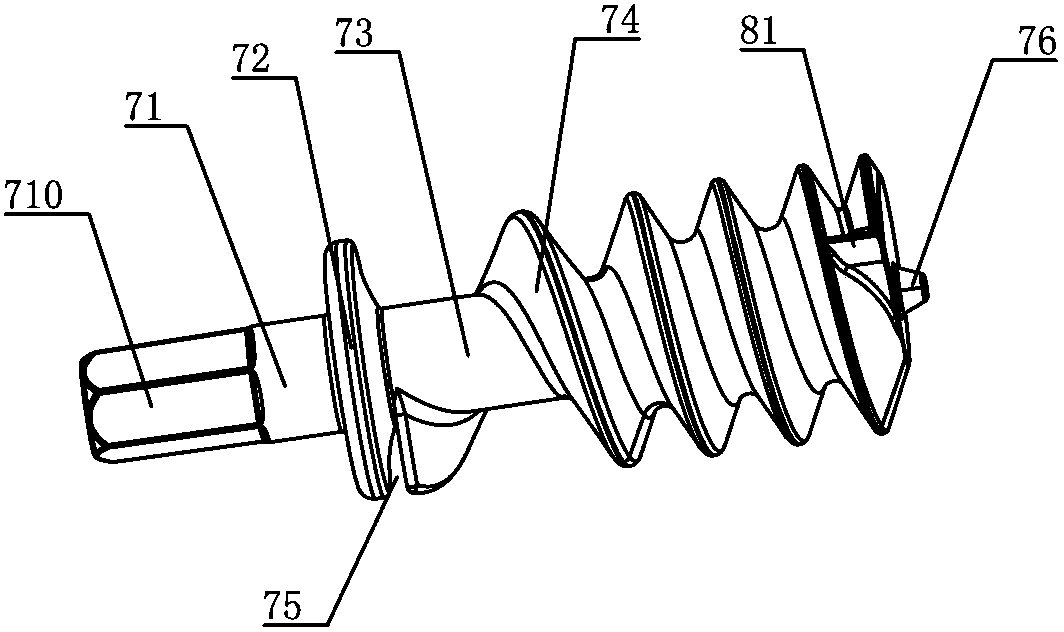

[0043] As the first embodiment of a safe noodle machine according to the present invention, as image 3 , 4 As shown, the screw 7 further includes a safety protection structure, and the safety protection structure includes a pressure relief rib arranged at the front end of the screw 7, and the pressure relief rib includes a first pressure relief rib 81 and a second pressure relief rib 81. The rib 82 is suppressed, and the thread 74 provided on the screw 7 is a single thread.

[0044] Such as image 3 , 4 As shown, the first pressure relief rib 81 is arranged at the end of the thread 74, located within the pitch formed by the screw 74, extends backward from the end of the thread 74 and connects with the adjacent thread 74 Connect, close the end outlet of the thread 74. The second pressure relief retaining rib 82 is located on the same plane as the first pressure relief retaining rib 81, and is 1.5 pitches away from the first pressure relief retaining rib 81, so that the sec...

Embodiment 2

[0056] As the second embodiment of a safe noodle machine according to the present invention, as Figure 6 As shown, the difference from the first embodiment is that the safety protection structure is a notch provided on the thread at the front end of the screw.

[0057] Such as Figure 6 , 7 As shown, the safety protection structure includes a first notch 91 and a second notch 92 arranged on the thread 74, the first notch 91 is arranged on the first circle of the thread at the end of the thread 74, the first A notch 91 and a second notch 92 are disposed on the same side of the screw 7 , with a pitch difference between the front and rear. The first notch 91 and the second notch 92 cut off the thread 74 and connect the front and rear pitches of the thread 74 .

[0058] Such as Figure 7 As shown, the shape of the first notch 91 is the same as that of the second notch 92 . The included angle between the centerline of the first notch 91 and the axis of the screw 7 is δ, 45°≤δ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com