Method for cleaning powder plate of sweet potato vermicelli extruding device and device for cooking powder plate

An extrusion device and technology of sweet potato vermicelli, applied in the field of maintenance of sweet potato vermicelli processing equipment, can solve the problems of affecting product safety and quality, the vermicelli plate is easily corroded and rusted, and increasing equipment loss, etc., and achieves simple structure, low loss, The effect of short burn time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

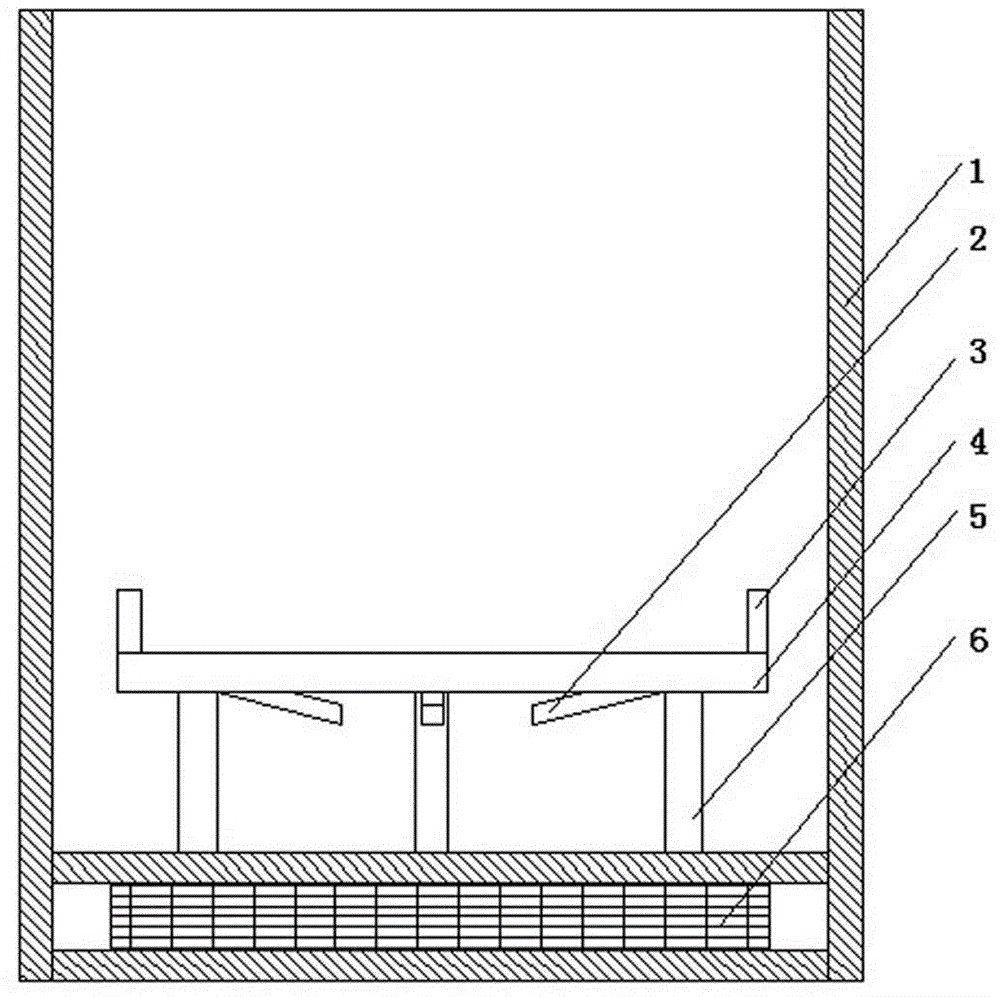

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0018] The powder plate cleaning method of the sweet potato vermicelli extrusion device includes the following steps:

[0019] a. Cooking powder plate: put the powder plate sticking with sweet potato starch on the bracket in the cooking powder plate barrel, add edible oil into the boiling powder plate barrel, so that the added edible oil can completely cover the powder plate, heat, Oil temperature 180-220 ℃ cook for 20-40 minutes;

[0020] b. Burning powder board: take out the powder board processed by the above steps, put it on the electric furnace and burn it for 10-15 minutes, and then cool it down;

[0021] c. Scrub the powder plate: wash the powder plate processed through the above steps in water for 5-10 minutes, so that the ashed sweet potato powder in the hole of the powder plate is completely separated from the powder plate;

[0022] d. Clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com