Inductor for divisionally and incrementally forming bimetal composite pipe

A bimetallic composite pipe and progressive forming technology, applied in the field of bimetallic pipe forming, can solve problems such as uneven distribution of electromagnetic force, sparse magnetic lines of force, damage to composite interface performance, etc., to improve bonding strength and composite rate, radial unevenness The effect of reducing the degree and increasing the metallurgical recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

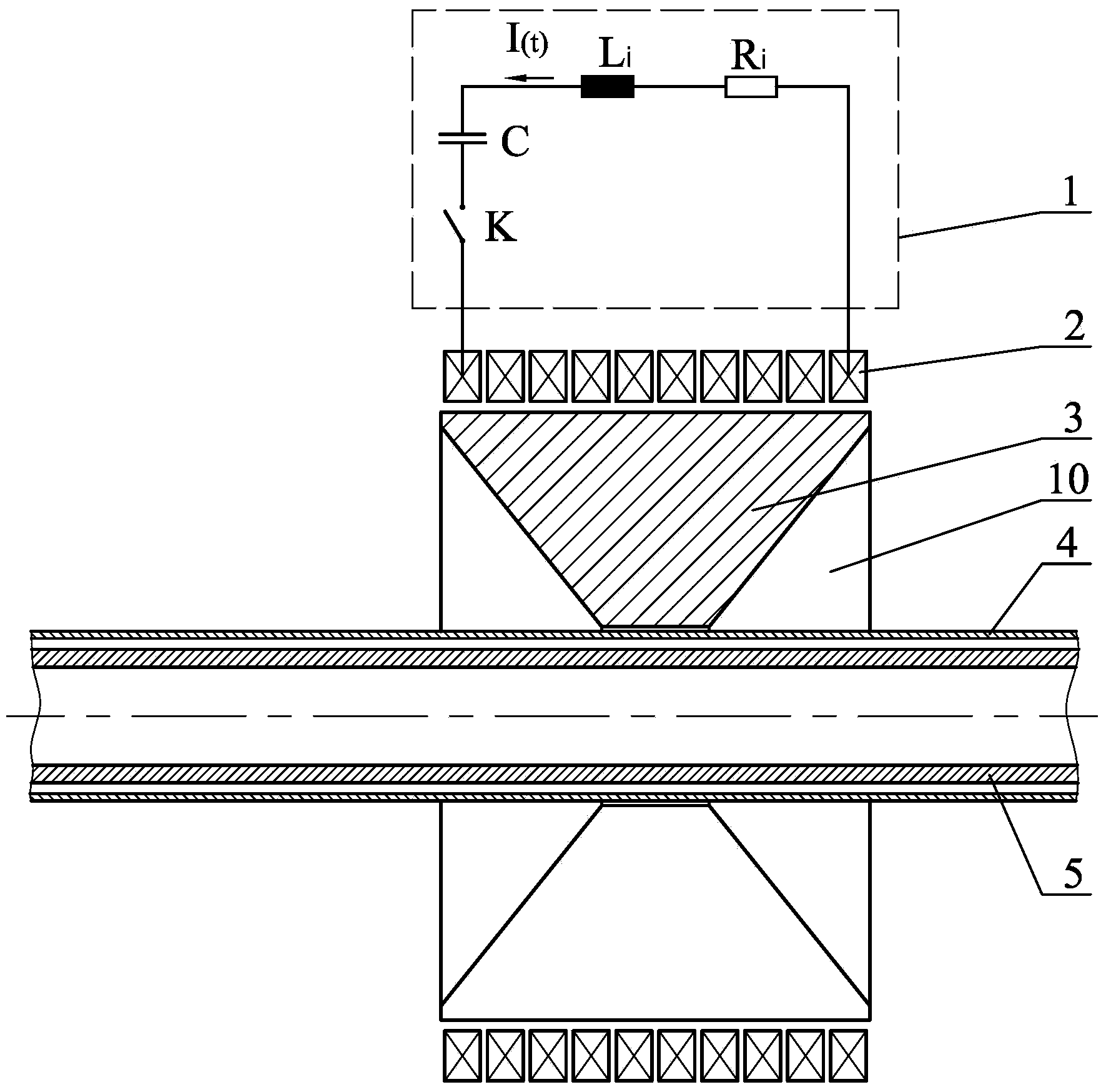

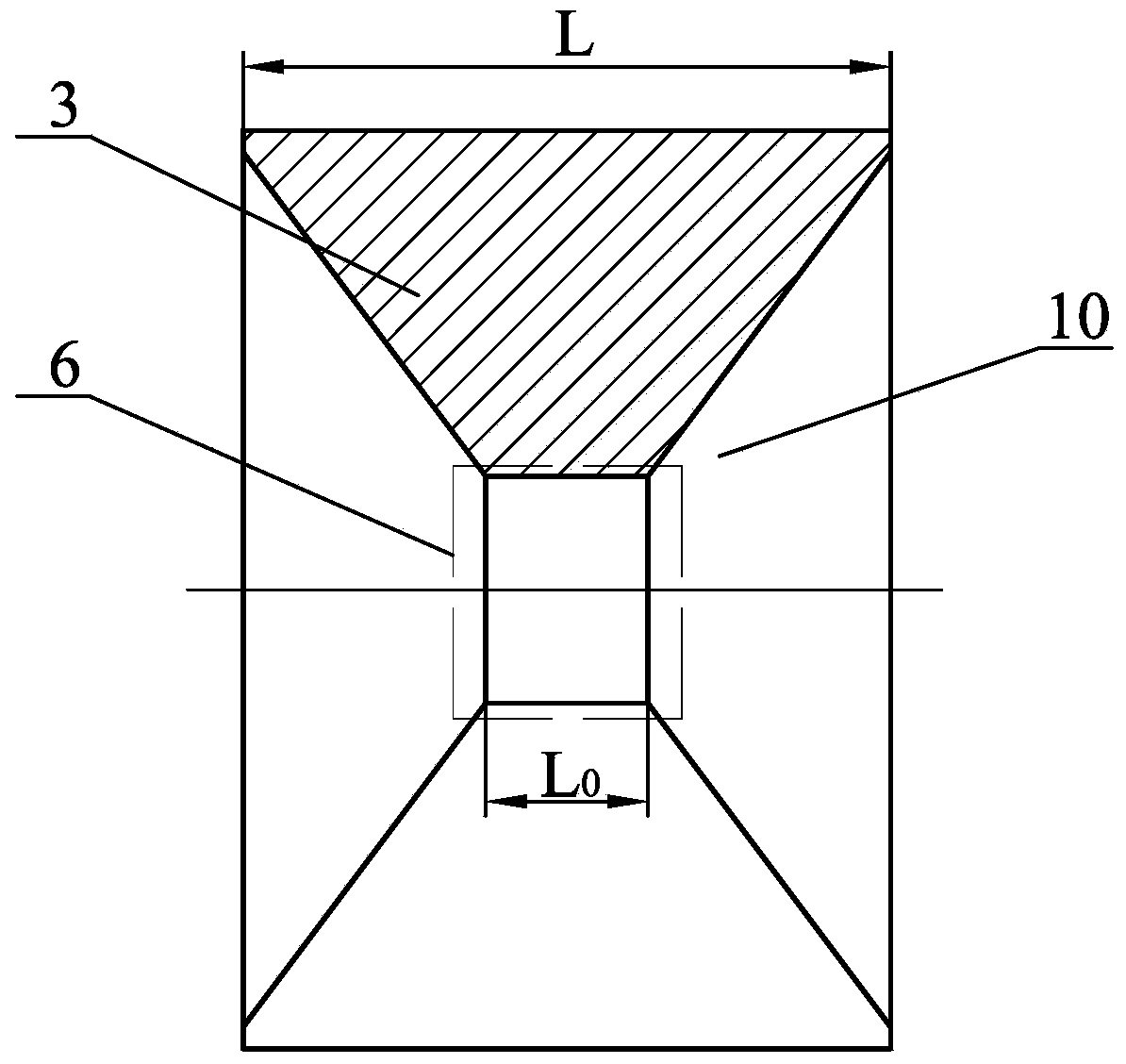

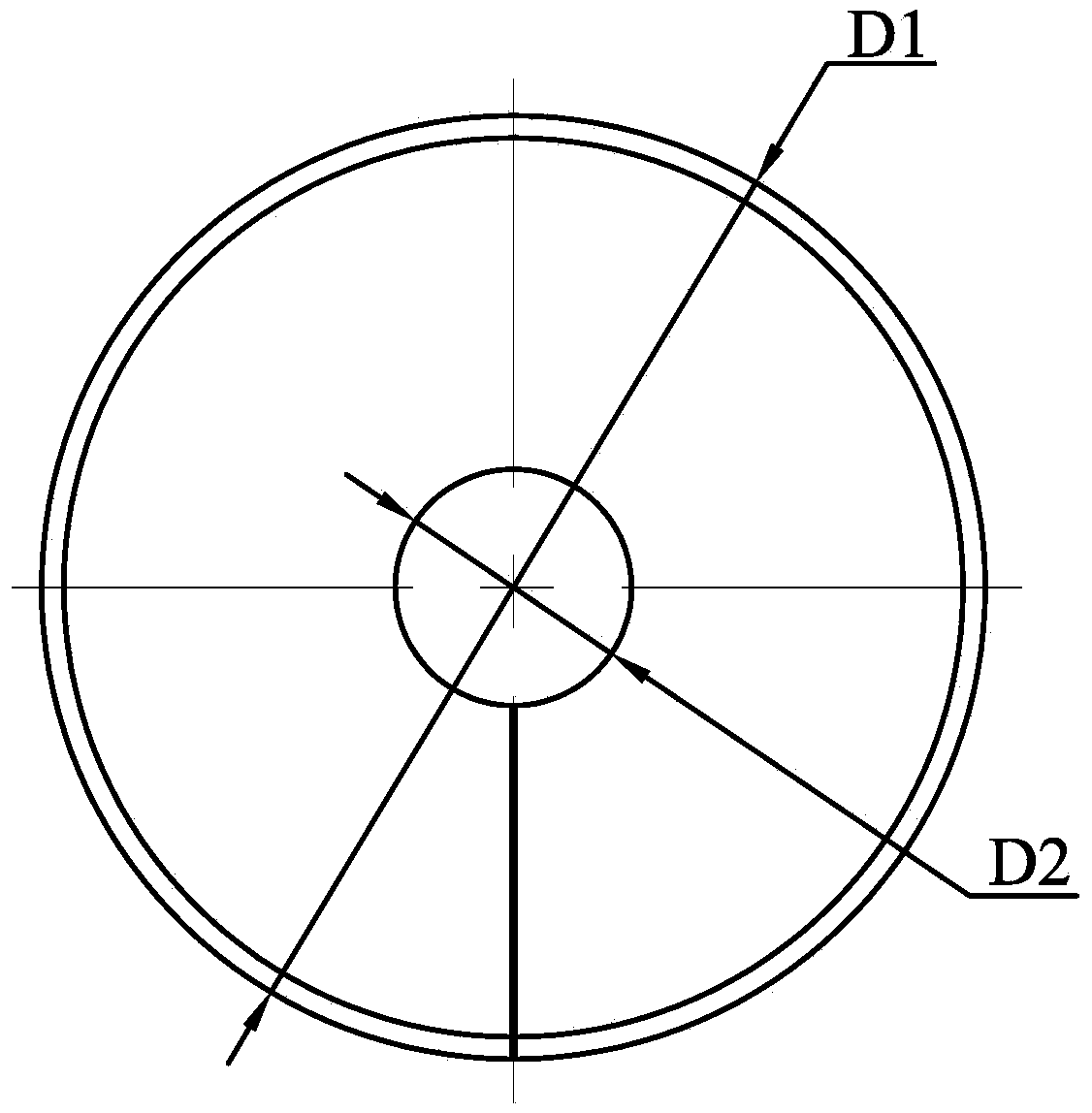

[0020] Specific implementation mode 1: Combination Figure 7 ~ Figure 10 It will be explained that, in this embodiment, an inductor for gradually forming a bimetallic composite tube by partitions has an outer shape of a cylinder 13, and the two ends of the cylinder 13 are respectively along the axial direction. A truncated truncated groove 10 is machined in the direction, and a mounting hole communicating with the two truncated truncated troughs 10 is machined in the middle of the cylinder 13, and the mounting hole is arranged coaxially with the two truncated truncated troughs 10. The enclosed area is the working area 6. The side wall of the cylindrical body 13 is radially provided with a long slit 14 communicating with the assembly hole. The assembly hole is composed of a large truncated cone hole 11 and a small truncated cone hole 12. The small diameter end of the truncated truncated hole 11 coincides with the large diameter end of the truncated truncated truncated hole 12, a...

specific Embodiment approach 2

[0028] Specific implementation manner two: combination Figure 7 It is explained that the axial length L2 of the small truncated cone-shaped hole 12 in this embodiment is 2 mm to 6 mm. The technical features not disclosed in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination Figure 7 It is explained that the connection between the large truncated cone-shaped hole 11 and the small truncated cone-shaped hole 12 is provided with a large transition fillet, and the radius of curvature of the large transition fillet is R1, R1=20mm, and the large truncated cone-shaped hole 11 is adjacent to The junction of the truncated cone-shaped groove 10 and the junction of the small truncated cone-shaped hole 12 and the adjacent truncated cone-shaped groove 10 are respectively provided with small transition fillets, and the radius of curvature of the small transition fillets is R2, R2=1mm. The technical features not disclosed in this embodiment are the same as those in the first embodiment.

[0030] The setting of the β angle is used to make the transition zone 7 preferentially deform; the setting of the α angle makes the radial gap between the inductor and the outer tube 4 gradually increase from right to left, fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com