Automatic submerged arc welding machine

An automatic submerged arc welding and submerged arc welding machine technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of low welding efficiency and difficult control of the welding quality of pressure vessel circumferential seams, so as to ensure the welding quality and The effect of welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Combine below Figure 1 to Figure 6 , the present invention is further described:

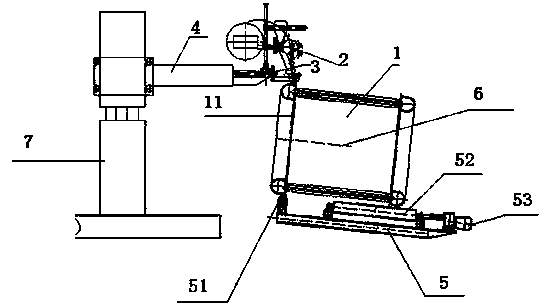

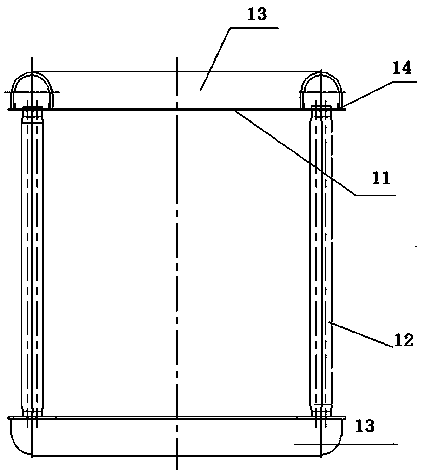

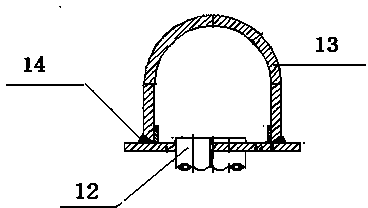

[0027] Such as figure 1 As shown, an automatic submerged arc welding machine, the submerged arc welding machine 2 is installed on the welding tracker 3, the boiler body 1 is set on the furnace body rotary tooling 5 for rotating motion, the U-shaped head of the boiler body 1 and the tube plate The joint is the weld seam that needs to be welded. The welding tracker 3 expands and contracts axially with the deformed tube sheet 11. This axis is also the rotation axis 6 of the furnace body, and the submerged arc welding machine 2 also performs telescopic movement correspondingly to ensure that the welding torch always follows the welding. The seam 14 is gone, thus ensuring the welding quality and welding efficiency.

[0028] Furnace body rotating tooling 5 includes installation platform, passive pulley group 51, roller group 51 and motor 53, motor 53 drives roller group 51 to rotate, roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com