Dual-freedom-degree locating pin

A technology of positioning pins and degrees of freedom, applied in the field of installation and positioning parts, can solve the problems of large amount of design, long manufacturing cycle, large space occupation, etc., and achieve the effect of simple structure design, short production period and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments.

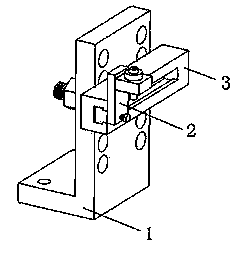

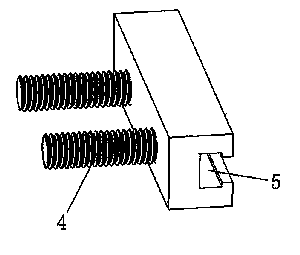

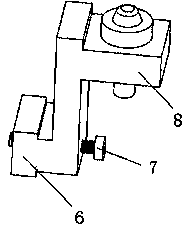

[0018] Such as figure 1 , figure 2 , image 3 As shown, a dual-degree-of-freedom positioning pin includes a base 1, and also includes a positioning base 2 and a sliding base 3 mounted on the base 1. The base 1 is an "L" structure with two symmetrical openings on the vertical plane. A row of positioning holes; the positioning seat 2 is a square structure, including a threaded column 4 and a guide groove 5. There are two threaded columns 4, and the two are symmetrically fixed on one side of the positioning seat 2. The cross section of the guide groove 5 is inverted. The T"-shaped structure is located on the other side of the positioning base 2; the sliding base 3 is a "Z"-shaped structure, including a guide block 6, a vertical plate and a positioning pin 8; the shape of the guide block 6 and the shape of the guide groove 5 It is matched and fixed on the bottom of the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com