An integrated device for partial cleaning, spraying and drying of automobiles

A local and clean technology, applied in spraying devices, liquid spraying devices, and devices that apply liquid to the surface, etc., can solve the problems of manual paint repairing failing to achieve paint repairing effect, and large equipment increasing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the following text, numerous specific details are set forth in order to provide a thorough understanding of the concepts underlying the described embodiments, however, it will be apparent to those skilled in the art that the described embodiments can be used without these specific details. Some or all instances were practiced, and in other instances well-known process steps were not described in detail.

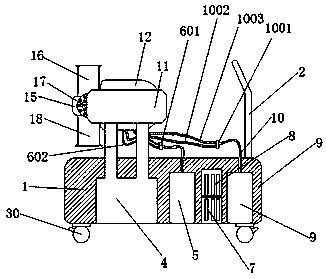

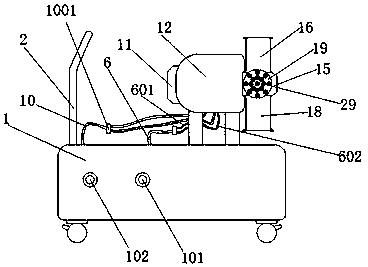

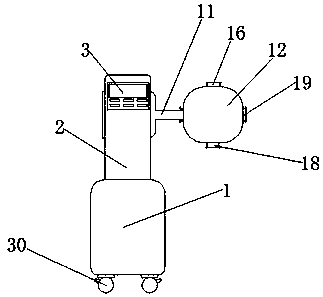

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, an integrated device for partial cleaning, spraying, and drying of automobiles, including a base 1, an operating console 2, a control panel 3, a first electric push rod 4, a first spray paint can 5, a first hose 6, and a first booster pump 7. The second booster pump 8, the second paint spray tank 9, the second hose 10, the second electric push rod 11, the fixed seat 12, the stepper motor 13, the rotating shaft 14, the rotating seat 15, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com