Multi-working-position precision-carving machine workbench side-mounted integrated tool magazine

An engraving machine, multi-station technology, applied in positioning devices, metal processing mechanical parts, manufacturing tools, etc., to achieve the effect of improving work efficiency and processing scope, accurate and reliable tool selection position, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

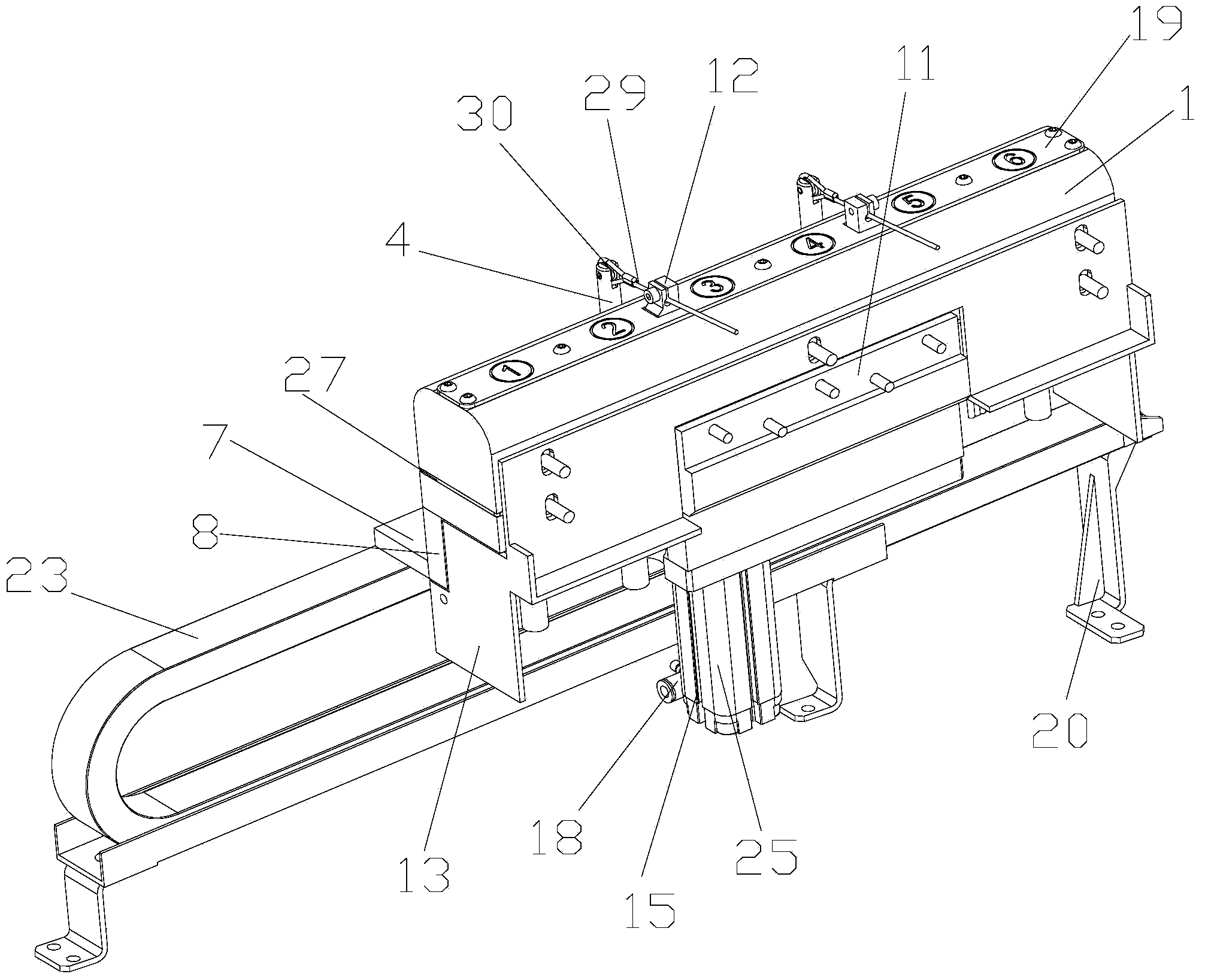

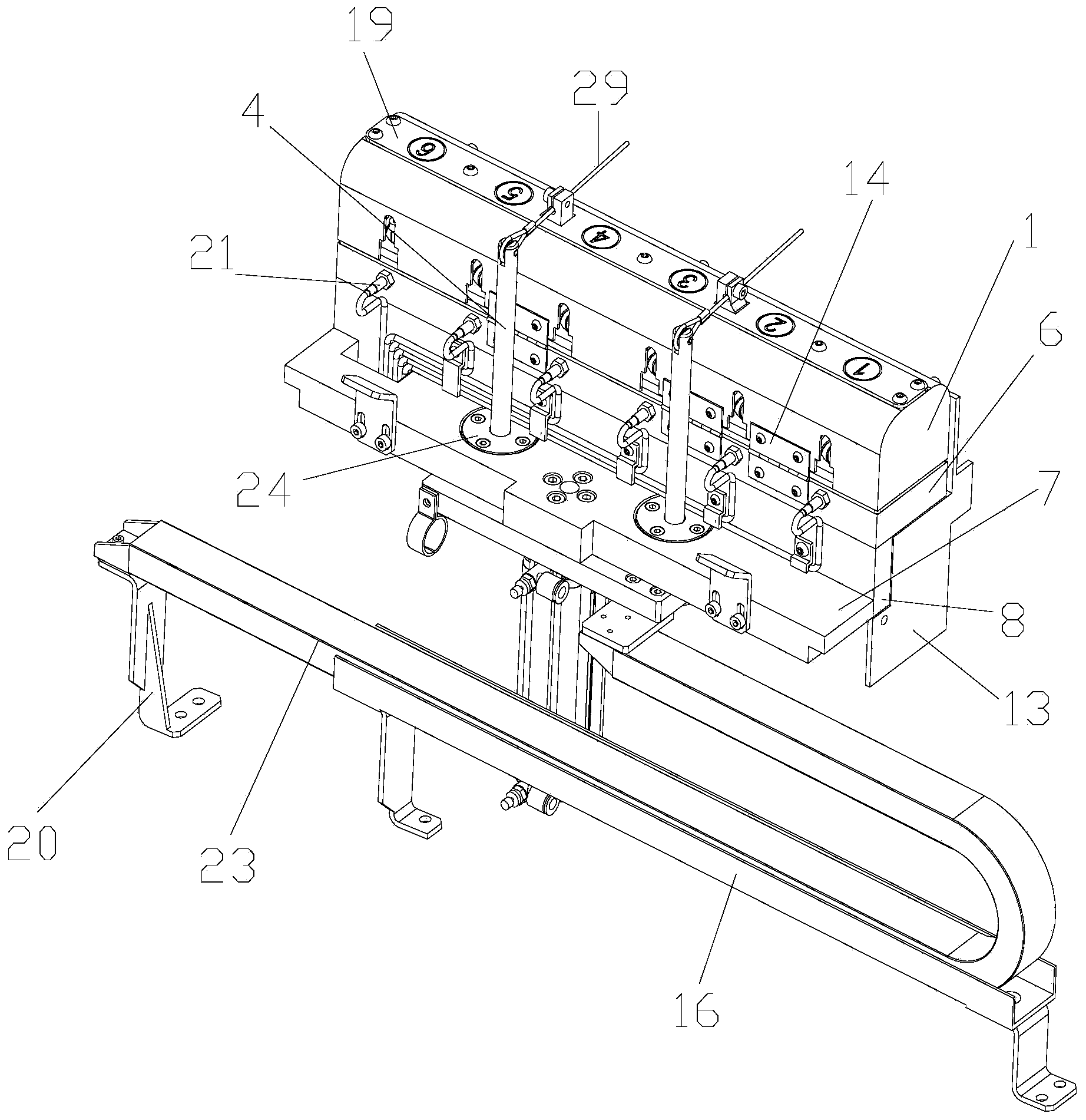

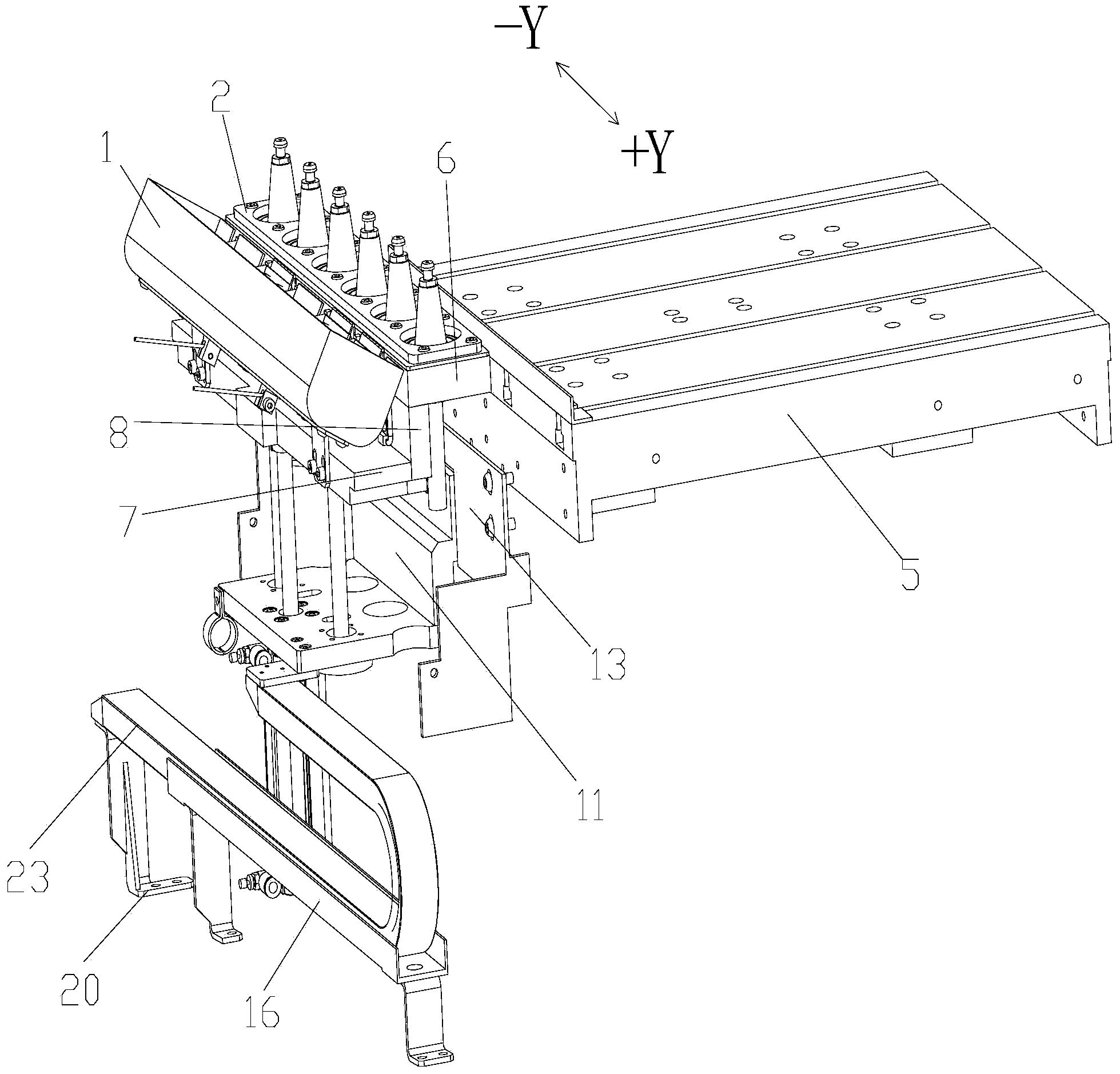

[0020] Attached below Figure 1-8 An embodiment of the present invention is described.

[0021] Multi-station engraving machine workbench side-mounted integrated tool magazine, including tool magazine protective cover 1, backing plate 6, cylinder connecting plate 7, vertical connecting plate 8 and cylinder 25, the lower end surface of the backing plate 6 and the vertical connecting plate 8, one end is fixedly connected, the other end of the vertical connecting plate 8 is fixedly connected to the cylinder connecting plate 7, the upper end surface of the backing plate 6 is equipped with a tool magazine sealing plate 2, and the tool magazine sealing plate 2 protrudes from the upper end surface of the backing plate 6, A tool magazine anti-collision pad 27 is provided on the upper end surface of the backing plate 6 along the periphery of the tool magazine sealing plate 2 . The hole for installing the knife handle pad 10 is equidistant along the Y-axis direction on the said knife m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap