Production equipment and production technology of low-cost large plastic element

A production process and technology for plastic parts, applied in the field of low-cost large-scale plastic parts production equipment and production process, can solve the problems of high price, waste of injection molding machines, little movement, etc., and achieve the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

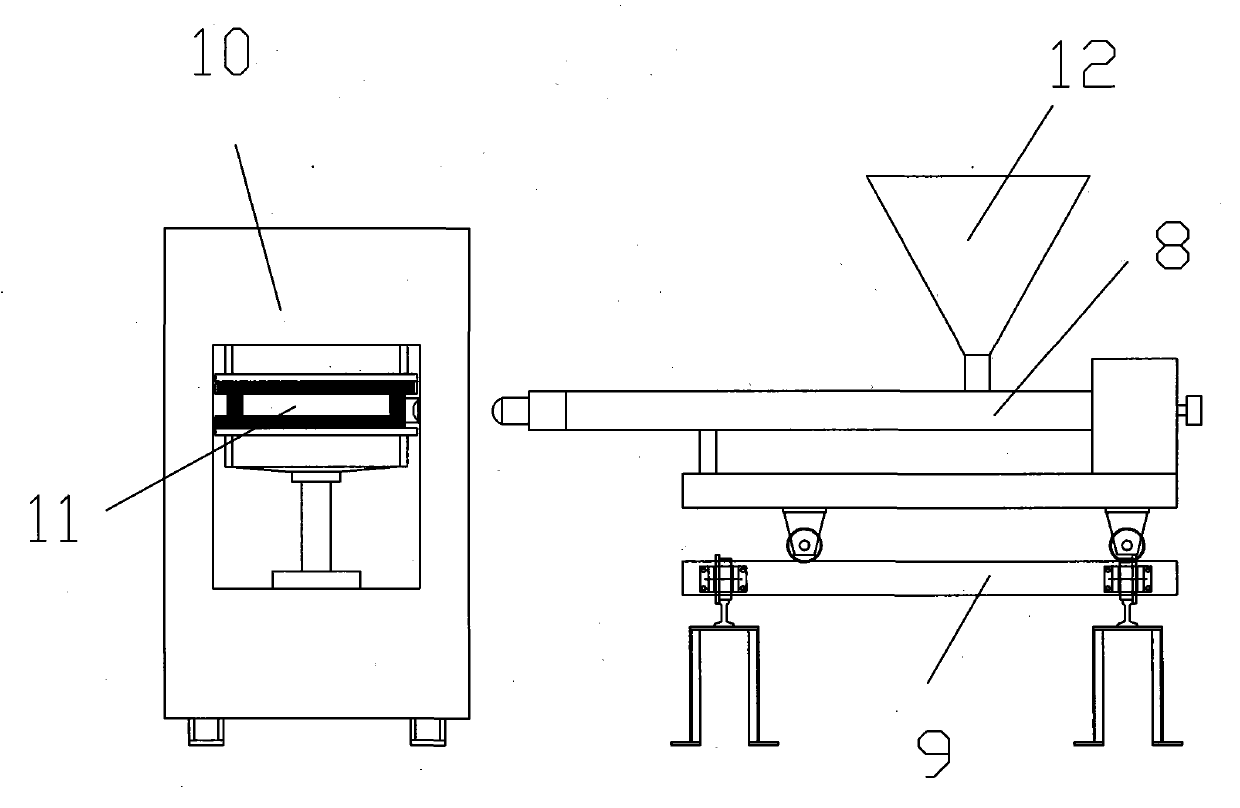

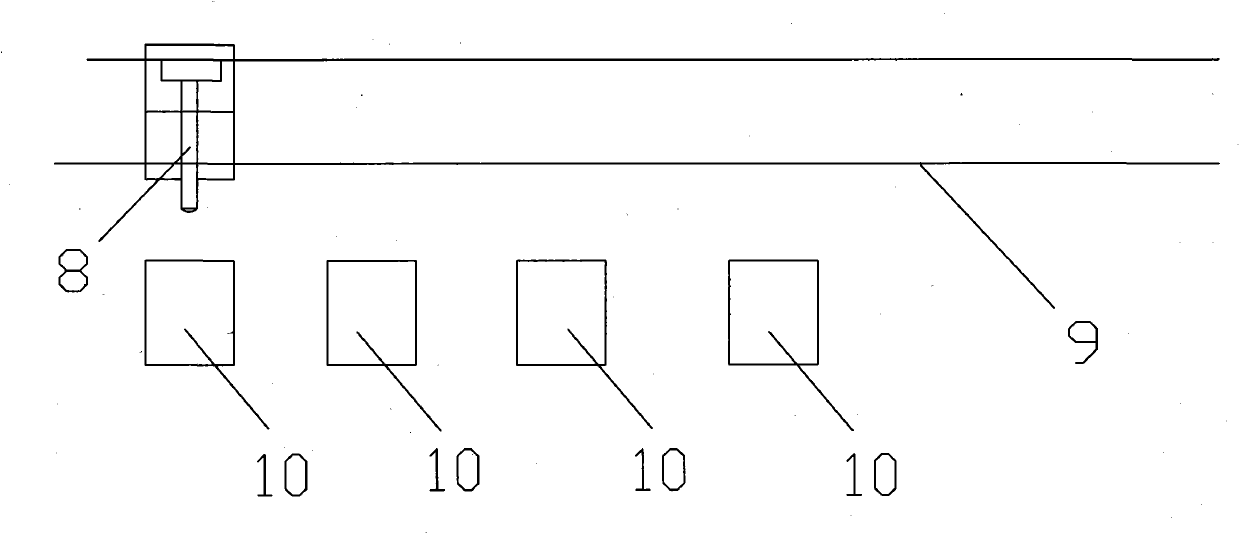

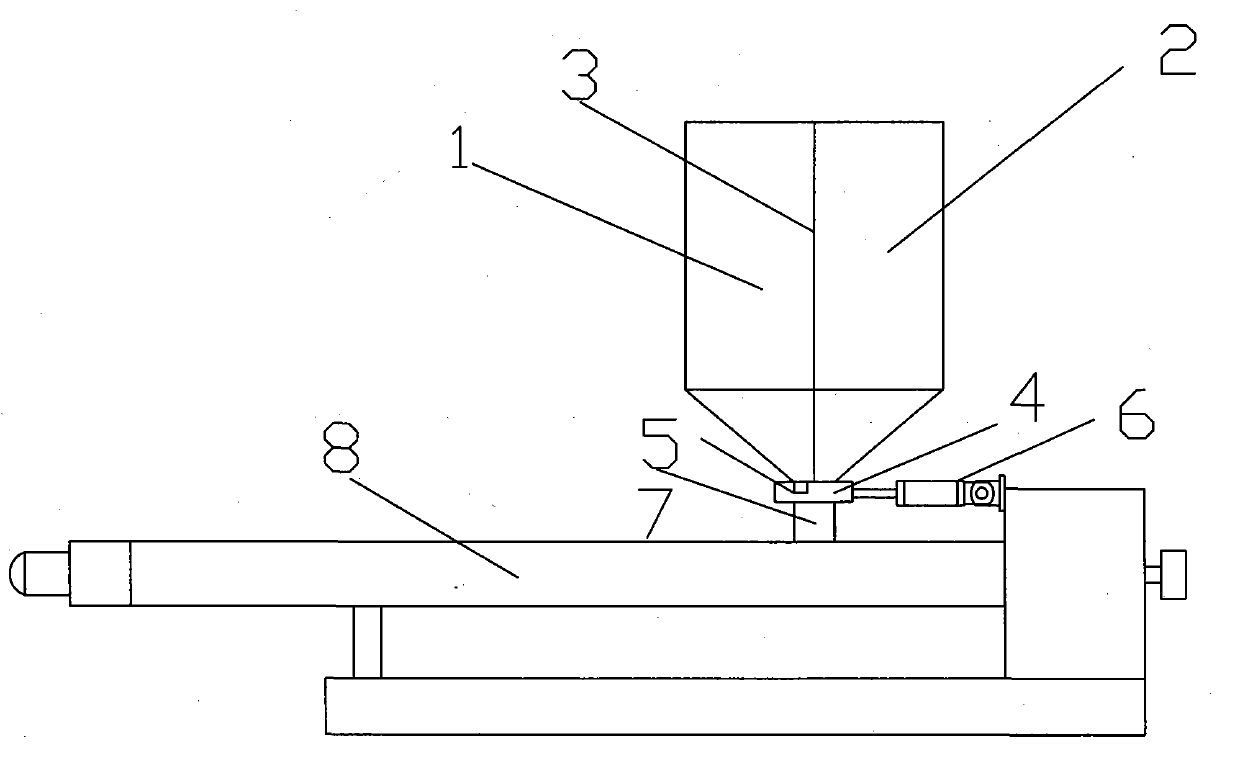

[0035] Embodiment 1: refer to Figures 1 to 3 ,

[0036] A low-cost production equipment for large plastic parts, including 1 extruder, 4 vulcanizers and 4 molds arranged in sequence along the guide rail, the vulcanizer is installed on the mold, the extruder is installed on the movable guide rail, extrusion There is a feeding device on the extruder, and the power device of the extruder is a hydraulic cylinder. The present embodiment adopts the extruder whose screw diameter is 105mm, the power of the extruder is 18.5 kilowatts, the mold clamping force of each vulcanizer is 500 tons, the mold clamping power is 1.5 kilowatts, and the production size is a plastic building formwork of 0.6m*0.6m.

[0037] Sensors and stoppers are installed on the mold. When the material in the extruder is added to the set amount in the mold, the sensor and the limiter will send out a signal, the feeding valve in the mold will be closed, and the extruder will no longer inject material into the mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com