A tracking filling part for filling machine

A filling machine and filling technology, which is applied in the field of pharmaceutical packaging machinery and food, can solve the problems of difficulty in guaranteeing filling quality, influence of filling area, large movement stroke, etc., and achieve less friction particles, low cost, and simple structure control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

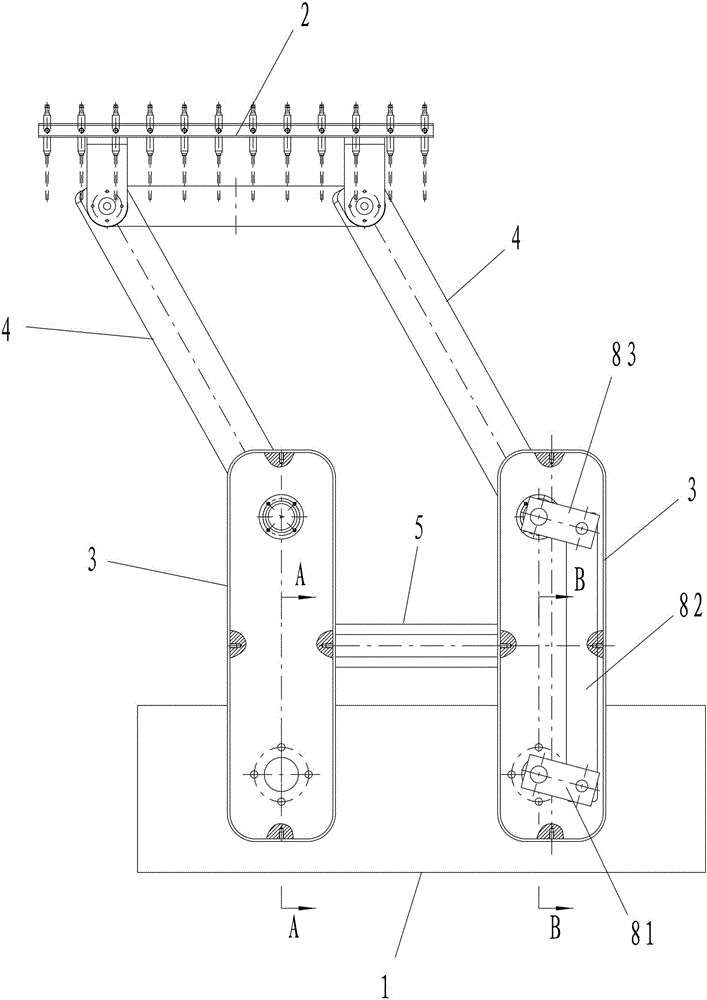

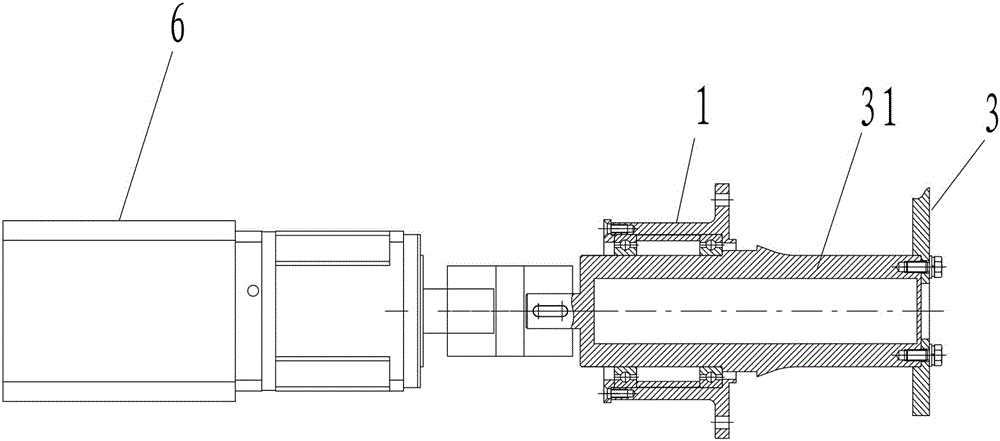

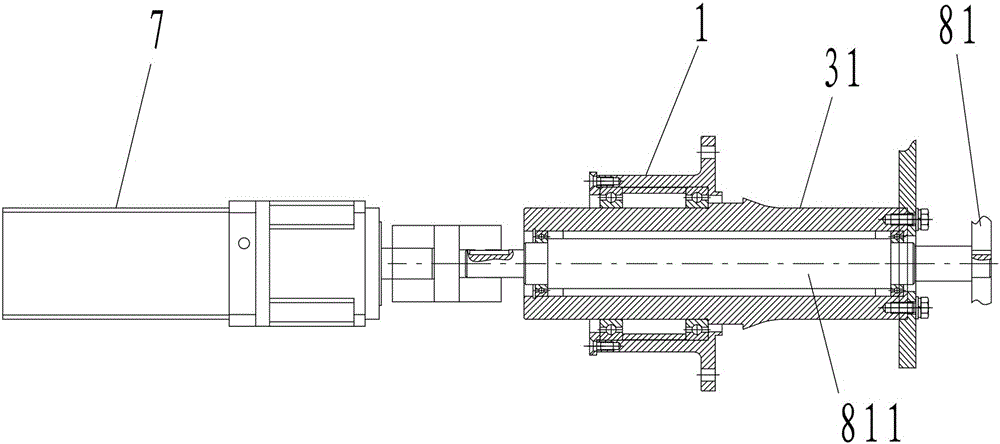

[0029] Such as figure 1 , Figure 4 As shown, the tracking filling part for the filling machine in this embodiment includes a frame 1, a needle filling frame assembly 2, two first swing arms 3 hinged on the frame 1 and a needle filling frame assembly hinged There are two second swing arms 4 on the 2, and the needle filling frame assembly 2 is provided with filling needles for filling. The first swing arm 3 and the second swing arm 4 located on the same side are hinged, and a connecting rod 5 is hinged between the two first swing arms 3 . One of the first swing arms 3 is connected with a first driving mechanism for driving the first swing arm 3 to swing around the frame 1, and one of the second swing arms 4 is connected with a drive mechanism for driving the second swing arm 4 to swing around the first swing arm 3. the second drive mechanism. The frame 1, the connecting rod 5 and the two first swing arms 3 form a parallelogram mechanism, and the needle irrigation frame assem...

Embodiment 2

[0037] Figure 7 to Figure 11 Embodiment 2 of the present invention is shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is: see Figure 7 , Figure 9 , Figure 11 , the second drive mechanism includes a second motor 7 and a fourth rod 84 and a fifth rod 85 that are hinged, the second motor 7 is installed on the frame 1, and the output shaft of the second motor 7 is connected to the fourth rod 84 It is fixedly connected and can drive the fourth rod 84 to rotate, and the fifth rod 85 is hinged to one of the second swing arms 4 . When working, the second motor 7 drives the fourth rod 84 to swing, and the fourth rod 84 drives the second swing arm 4 to swing through the fifth rod 85 . Compared with Embodiment 1, the structure of the second driving mechanism of this embodiment is simpler. The principle of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com