Preparation method of high-strength high-elasticity modulus titanium matrix composite

A titanium-based composite material and high-elasticity technology, which is applied in the field of preparation of high-strength and high-elastic-modulus titanium-based composite materials, can solve the problems of poor rigidity, thick and heavy, and easy deformation of titanium alloys, so as to improve plasticity and strength. , boron and carbon have less volatilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The high-strength and high-elastic-modulus titanium-based composite material of this embodiment is composed of the following components in mass percentage: Al6.0%, V4.0%, Y0.15%, B0.5%, C0.5%, The balance is titanium and unavoidable impurities.

[0037] The preparation method of the titanium-based composite material of the present embodiment is:

[0038] Step 1. Mix and press the sponge titanium and boron to form an electrode block, then place the electrode block in a vacuum electric arc furnace and smelt it twice to obtain a Ti-5B alloy ingot, and then turn the Ti-5B alloy ingot turning chips into The Ti-5B master alloy is obtained by chipping or breaking into granules; the process parameters of the first melting are as follows: the melting current is 1200A, the voltage is 25V, and the vacuum degree is 6.5×10 -2 Pa; the process parameters of the second smelting are: the melting current is 2000A, the voltage is 25V, and the vacuum degree is 6.5×10 -3 Pa;

[0039] Ste...

Embodiment 2

[0045] The high-strength and high-elastic-modulus titanium-based composite material of this embodiment is composed of the following components in mass percentage: Al6.0%, V4.0%, Y0.1%, B0.5%, C0.5%, The balance is titanium and unavoidable impurities.

[0046] The preparation method of the titanium-based composite material in this example is the same as that in Example 1.

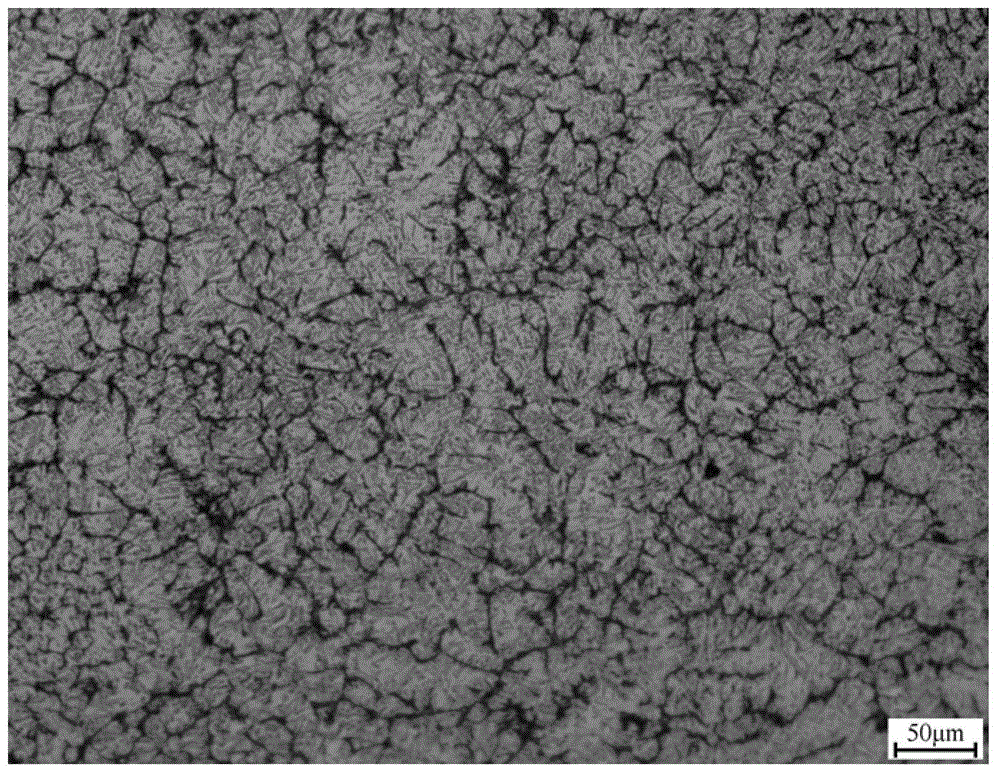

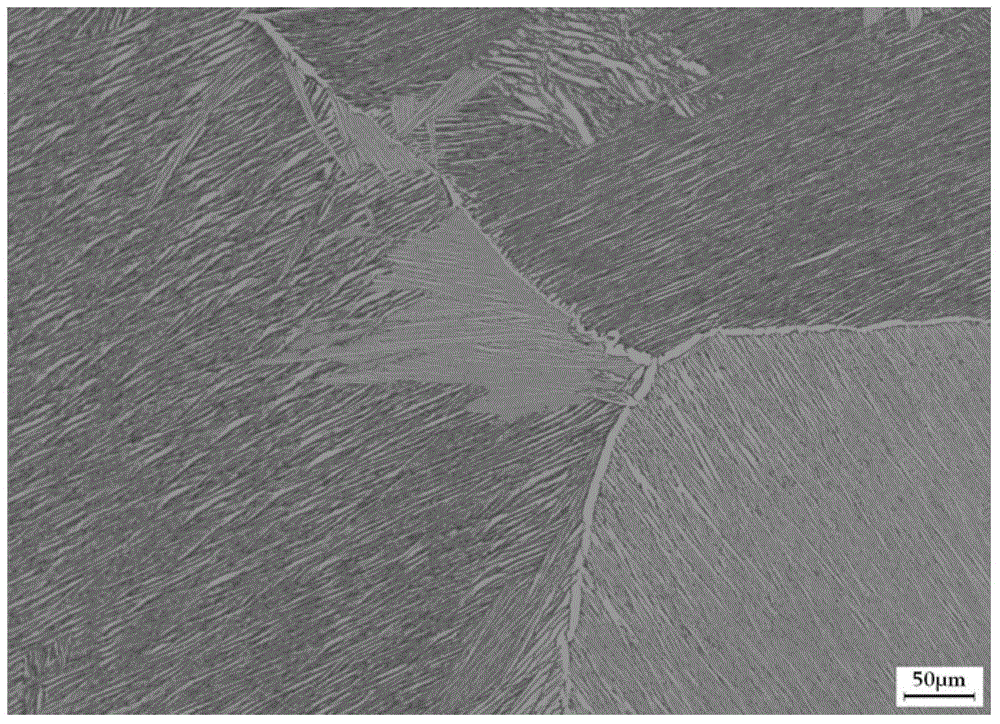

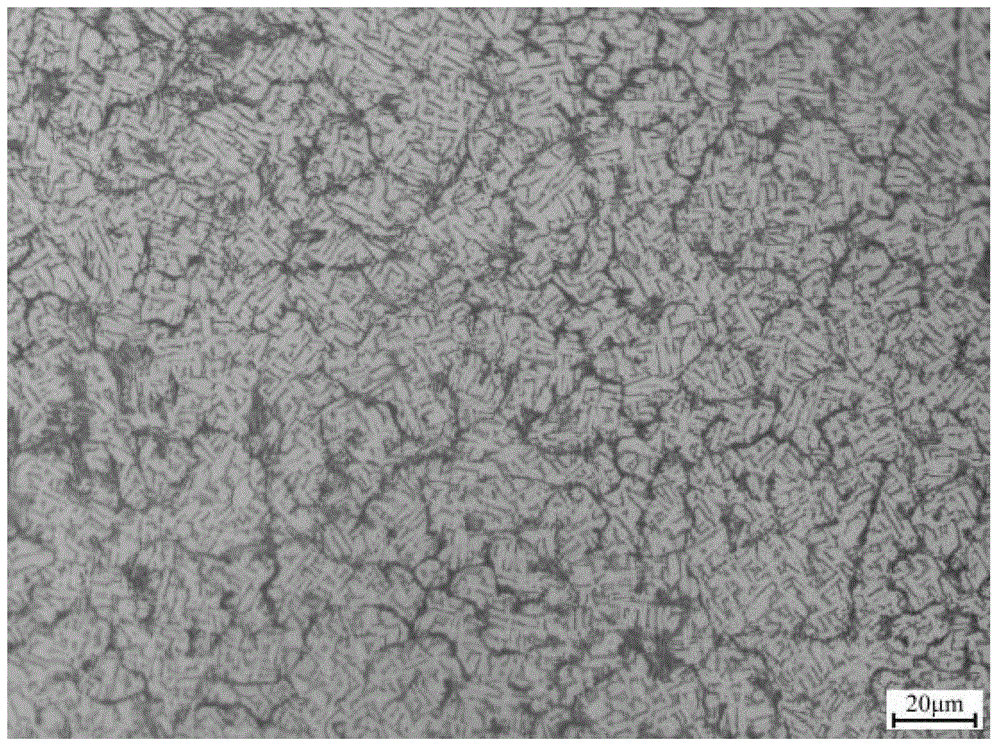

[0047] The microstructure grains of the titanium-based composite material in this example are obviously refined, and its microstructure consists of α phase (lamellar or spherical), grain boundary β phase, short rod-shaped second phase TiB phase, and irregular spherical The second phase TiC phase composition is granular and embossed.

Embodiment 3

[0049] The high-strength and high-elastic-modulus titanium-based composite material of this embodiment is composed of the following components in mass percentage: Al6.0%, V4.0%, Y0.18%, B0.5%, C0.5%, The balance is titanium and unavoidable impurities.

[0050] The preparation method of the titanium-based composite material in this example is the same as that in Example 1.

[0051] The microstructure grains of the titanium-based composite material in this example are obviously refined, and its microstructure consists of α phase (lamellar or spherical), grain boundary β phase, short rod-shaped second phase TiB phase, and irregular spherical The second phase TiC phase composition is granular and embossed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com