Front shovel excavating and loading device capable of automatically realizing bucket lifting energy saving and meeting translation requirement

A loading device and bucket technology, which is applied to mechanically driven excavators/dredgers, etc., can solve the problems of inability to meet the transmission requirements at the same time, the structure of the excavator is single, and the excavation range is limited, so as to achieve energy-saving requirements and optimize driving The effect of arm lift force and motion analysis is easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

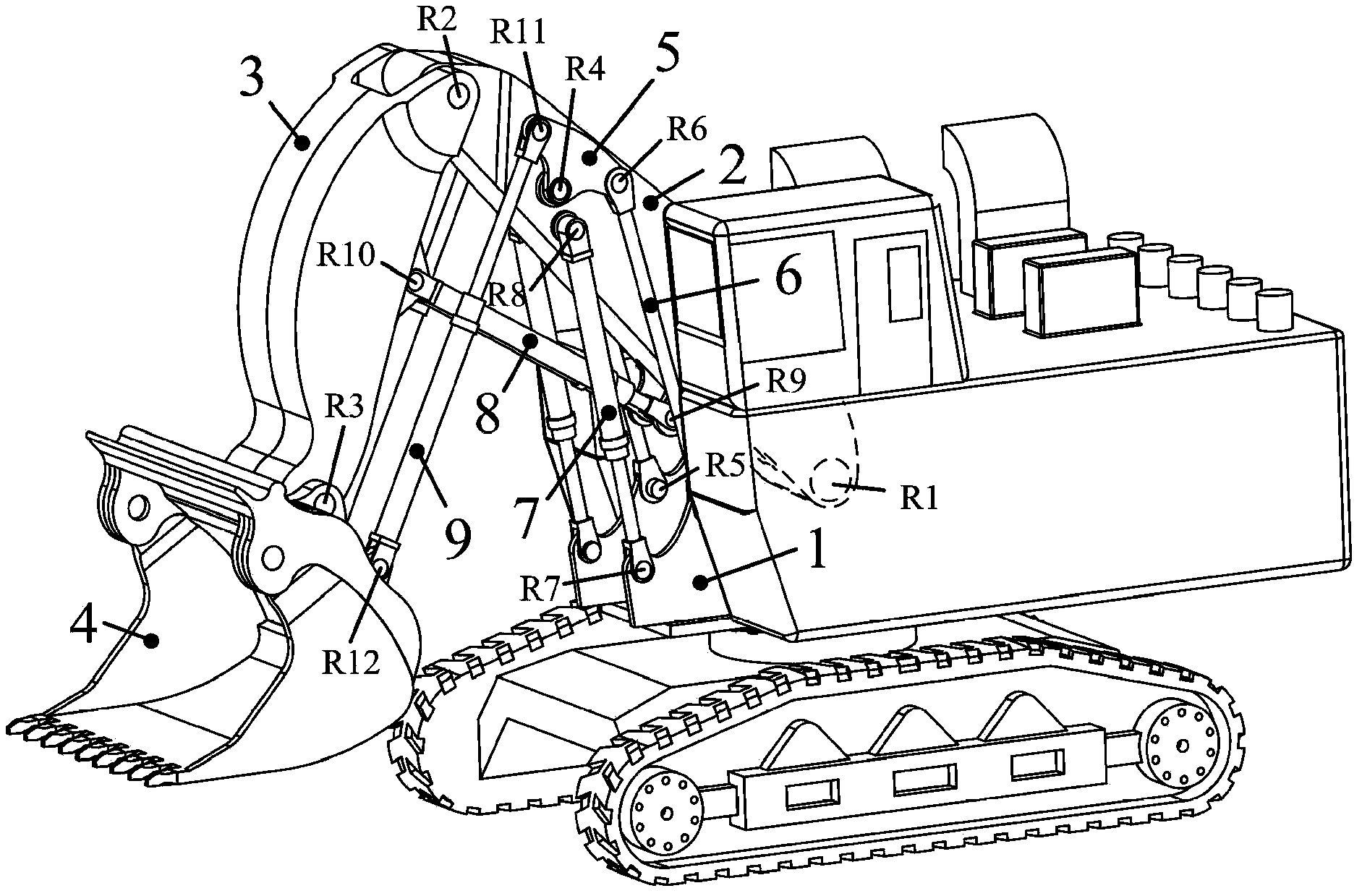

[0012] exist figure 1 In the schematic diagram of the front shovel digging and loading device that can automatically realize bucket lifting, energy saving and translation requirements, the lower end of the boom 2 is hinged to the frame 1 through the hinge R1, and the upper end of the boom is connected to one end of the stick 3 through the hinge R2. Hinged, the other end of the stick is hinged with a part of the bucket 4 through the hinge R3; a pair of boom rockers 5 are symmetrically hinged on both sides of the middle of the boom through the hinge R4, and the pair of boom rockers One end of a pair of connecting rods 6 is hinged through a hinge R6, and the other end of the pair of connecting rods is hinged with the frame through a hinge R5; the cylinder sleeve ends of a pair of boom hydraulic cylinders 7 are respectively connected to the above-mentioned boom through a hinge R8. The other part is hinged. The piston rod ends of the pair of boom hydraulic cylinders are hinged with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com