A Transition Section Structure of High and Low Pressure Turbine

A low-pressure turbine and high-pressure turbine technology, applied in gas turbine devices, jet propulsion devices, machines/engines, etc., can solve problems such as restricting applications, and achieve the effects of reducing inlet flow coefficient, shortening axial span, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

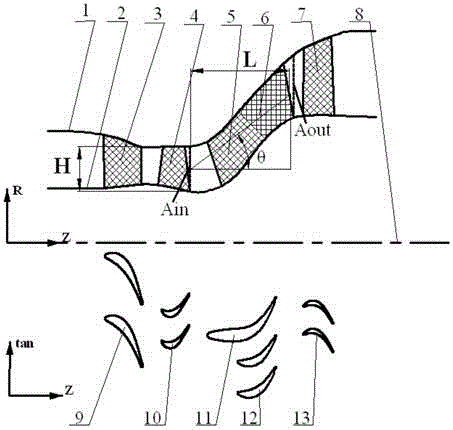

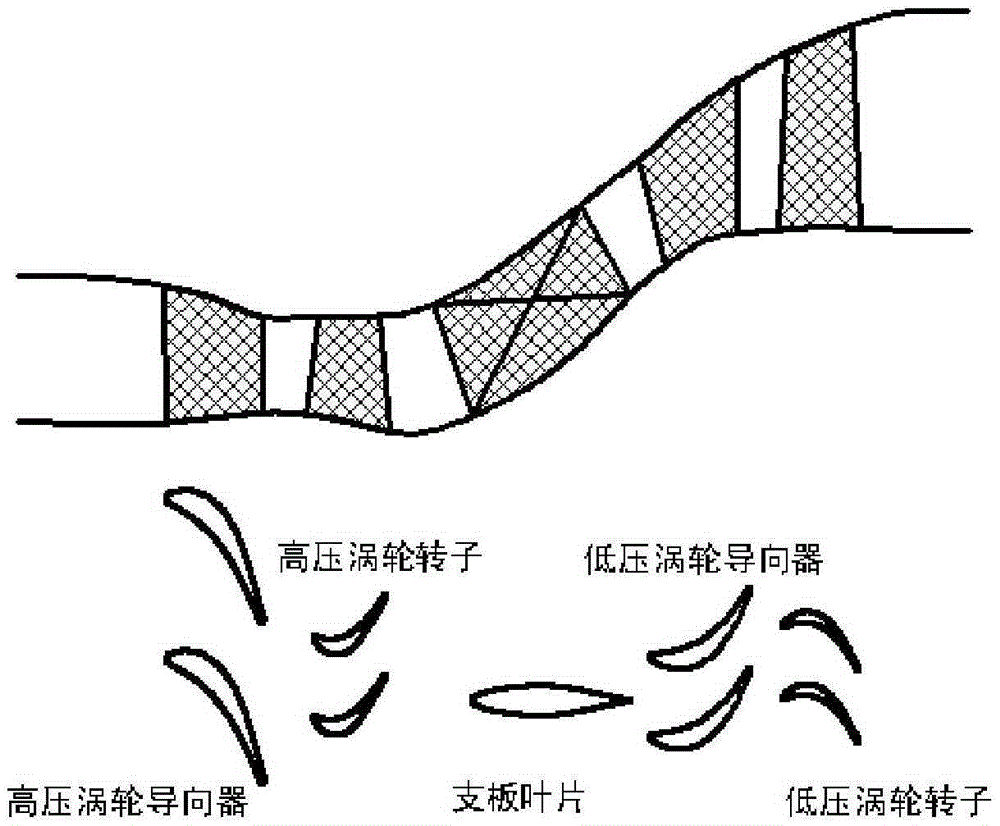

[0018] Such as figure 2 Shown, the high-low pressure turbine transition section that is used for aero-engine of the present invention is an annular passage that is formed by transition section inner end wall 1 and transition section outer end wall 2, and its inlet is connected with high-pressure turbine stage outlet, and its outlet is connected with low-pressure turbine stage. The inlet of the turbine stage is connected, and a row of large and small blades composed of a transition section support plate 5 and a low-pressure turbine guide 6 is arranged in the annular passage. And the trailing edge of each short blade of the low-pressure turbine guide is aligned with the trailing edge of the long blade of each strut plate, and the long blade o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com