Multi-cam self-adaptive multi-gear automatic transmission countershaft

An automatic transmission, self-adaptive technology, applied in the direction of the transmission box, the components with teeth, etc., can solve the problems of reducing the sense of frustration, etc., to achieve the effect of reduced volume, smooth load change, simple and compact structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

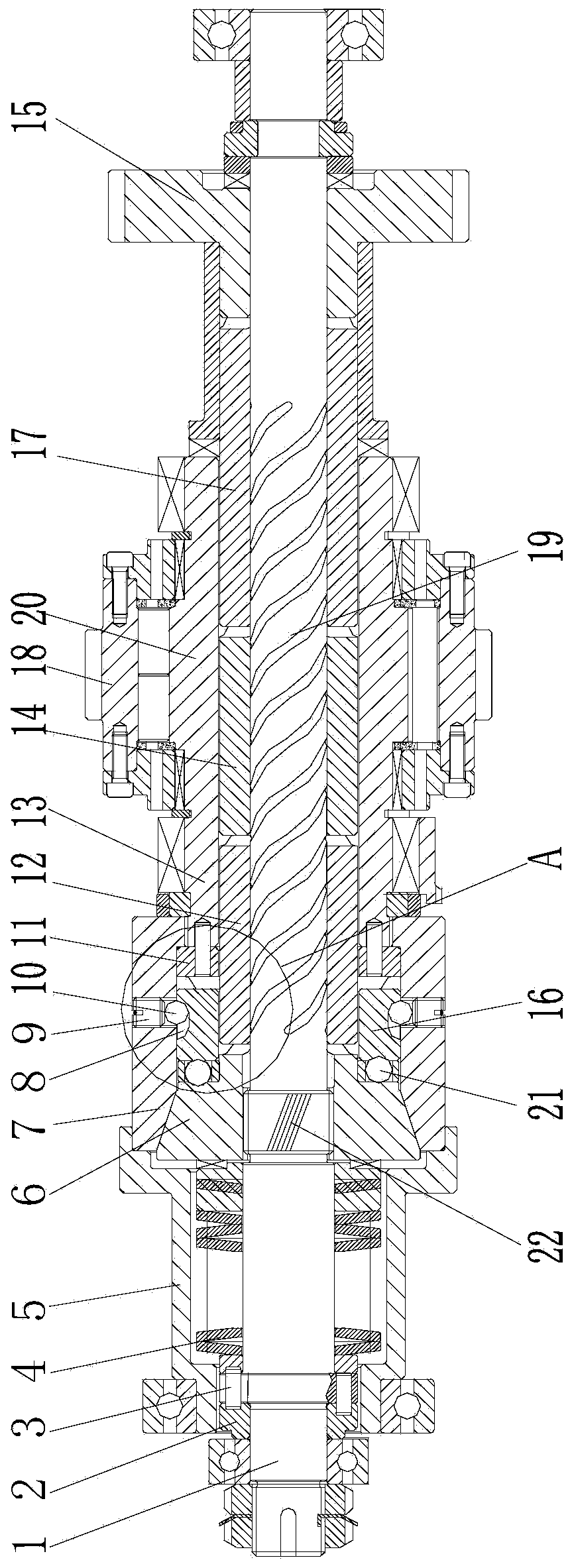

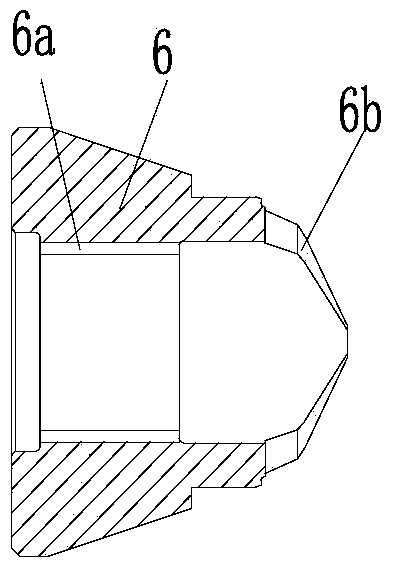

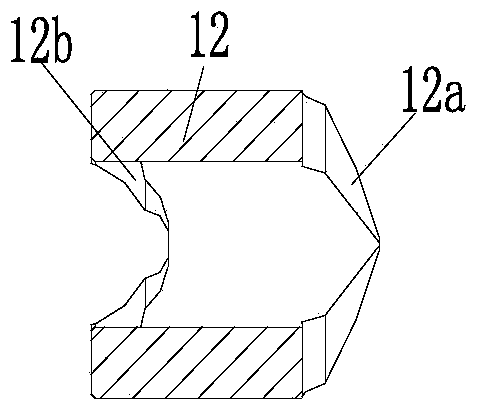

[0033] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is a schematic diagram of the structure of the axial outer taper sleeve of the torus, image 3 is a schematic diagram of the cam sleeve structure, Figure 4 It is a schematic diagram of the end face cam expansion of the cam bushing, Figure 5 for figure 1 Enlarged view at A, Figure 6 Schematic diagram of the structure of the overrunning clutch, Figure 7 for Figure 6 Enlarged view at C, Figure 8 for Figure 6 Sectional view along B-B direction, as shown in the figure: the multi-cam self-adaptive multi-speed automatic transmission sub-shaft of the present invention includes a support shaft 1 and a mechanical intelligent self-adaptive transmission assembly located on the support shaft 1, and the mechanical intelligent self-adaptive transmission The assembly includes an overrunning clutch, an axially outer tapered sleeve 6 of the annular body, an axially inner tapered sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com