Sealed material returning valve with two-way material returning control function

A two-way control and return valve technology, which is applied to the direction of burning fuel in the melting state, lighting and heating equipment, fluidized bed combustion equipment, etc., to achieve the effect of simple structure, not easy to wear, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

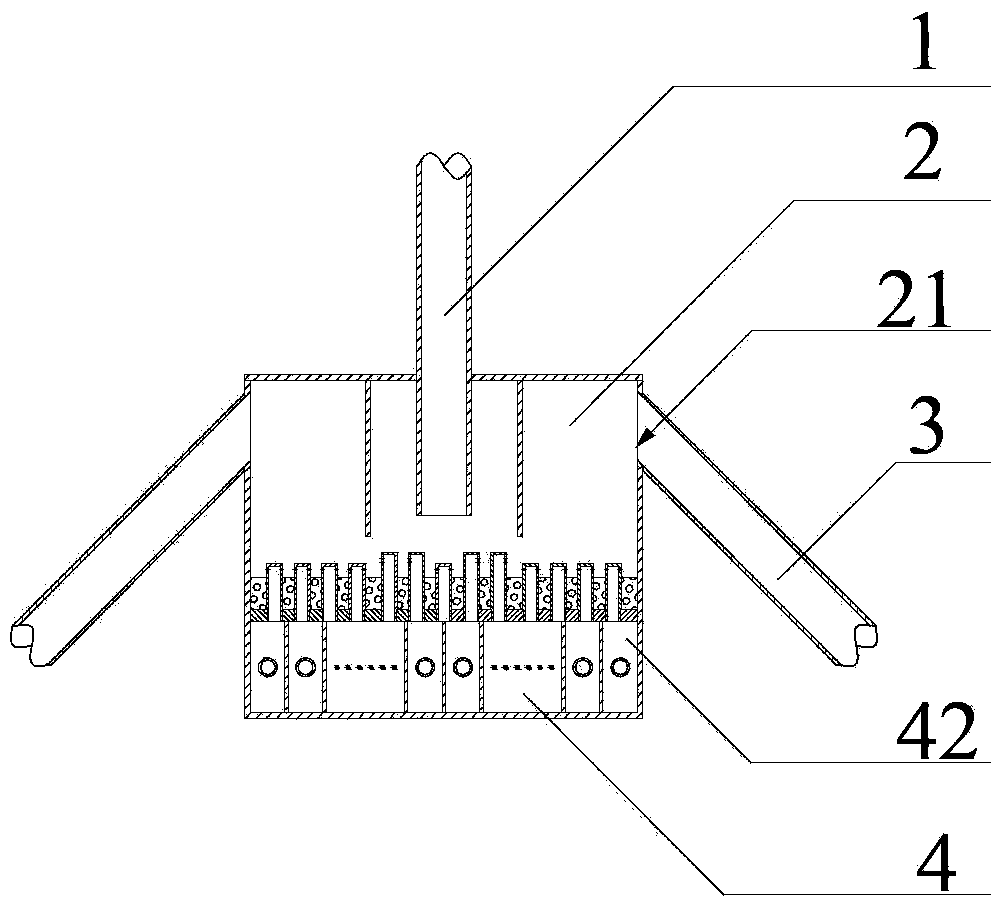

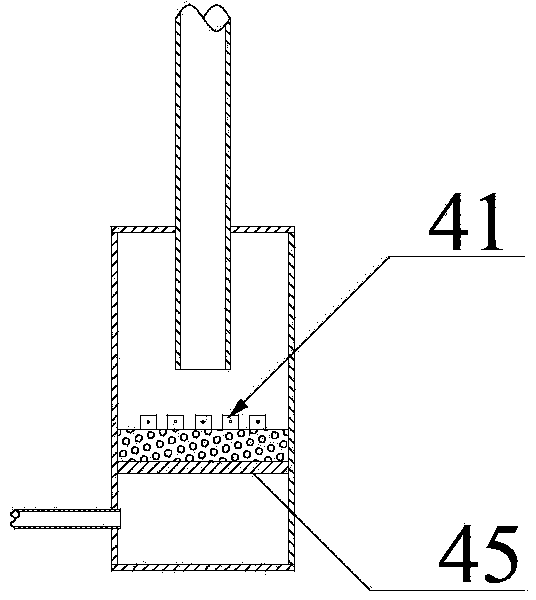

[0020] Such as figure 1 , 2 and 3 show embodiment 1, a sealed return valve that can control the return in two directions, including a descending section 1, two ascending sections 2 and an air chamber 4 at the bottom connected to the first three, and the main body of the return device is a cuboid structure The cross section of the rising section 2 is rectangular, and the return section 3 is connected to the rising section 2 through the overflow port 21, and the overflow ports 21 of the rising section 2 on both sides are equal in height; the air chamber 4 adopts a hood type air distribution plate 45, and It is divided into n independent air chambers 42 by partitions, and each independent air chamber 42 is connected with an air duct 43 which can independently adjust the air volume.

[0021] After the circulating material is separated from the separator, it is sent to the descending section 1 through the standpipe, and under the action of the fluidizing wind from the wind cap 41,...

Embodiment 2

[0023] Such as Figure 4 , 5 Shown is embodiment 2, a sealed return valve that can control the return material in two directions, including a descending section 1, two ascending sections 2 and an air chamber 4 connecting the bottom of the three. The main body of the returner is a cuboid structure; the ascending section The cross section of 2 is rectangular, and the return section 3 is connected to the rising section 2 through the overflow port 21, and the overflow ports 21 of the rising section 2 on both sides are equal in height; the air chamber 4 has n air ducts 43 that can independently adjust the air volume and The air pipe 43 is connected with the horizontal direction at an angle of 30-45 degrees to discharge the slag of the air cap. Each air pipe 43 is connected with m vertical branch pipes 44. The top of the vertical branch pipe 44 is the air cap 41, and the vertical branch pipe 44 and the air duct 43 are flexibly connected with a compensator.

[0024] After the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com