A sliding block groove center distance detector and its measuring method

A detector and center distance technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of difficulty in ensuring measurement accuracy, low measurement efficiency, and high labor intensity, and achieve the effects of easy automatic measurement, reduced labor intensity, and no maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

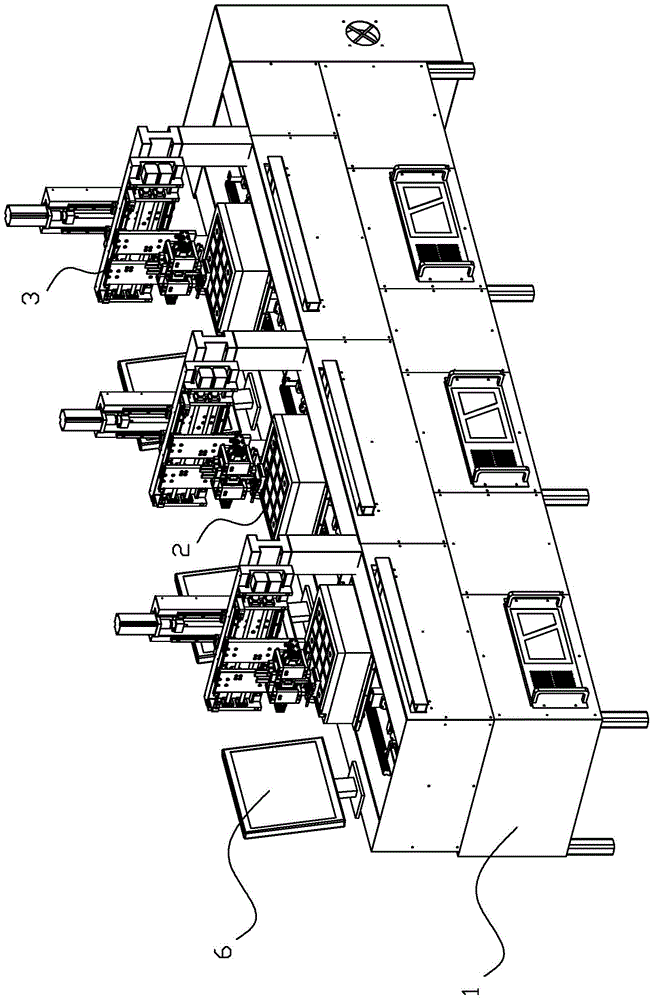

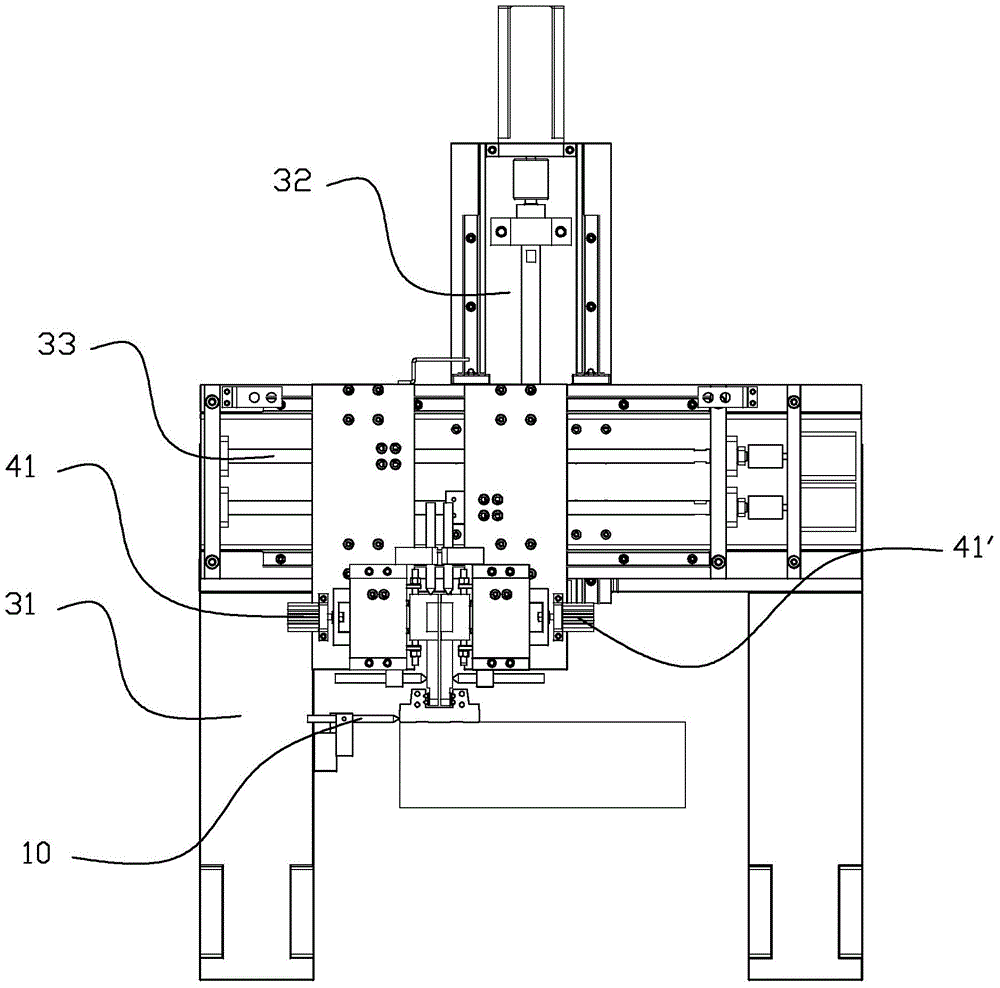

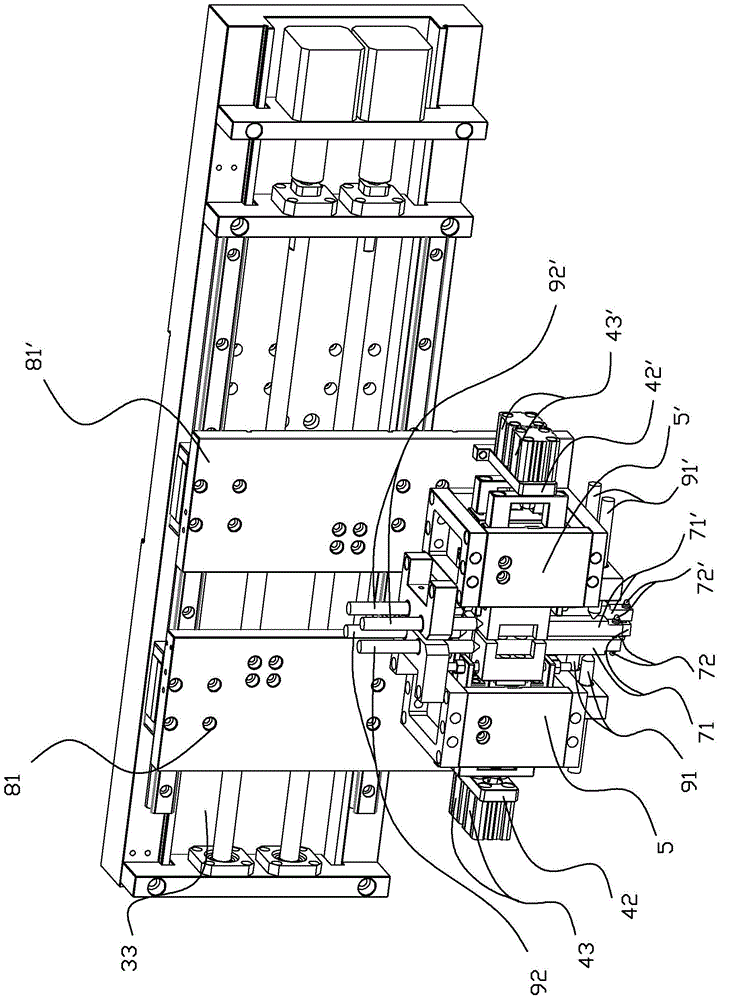

[0030] refer to Figure 1~Figure 5 , a slider groove center distance detector, which includes a frame 1, the frame 1 is slidably installed with a workbench 2 that can move forward and backward for clamping the auxiliary slider of the guide rail, and the frame 1 is fixedly installed with The gantry detection mechanism 3, the gantry detection mechanism 3 includes a gantry 31, the gantry 31 is provided with an up and down moving assembly 32, the up and down moving assembly 32 is equipped with a left and right moving assembly 33, and a left and right moving assembly 33 is slidably installed with a left , right carriage 81,81', left and right carriage 81,81' are respectively equipped with left and right groove detection mechanism 41,41', left and right groove detection mechanism 41,41' include being installed on the left, right The cylinder mounting plate 42,42' on the right carriage 81,81', the left and right cylinder 43,43' are fixed on the cylinder mounting plate 42,42', and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com