On-line paper cup leakage detecting device and control method thereof

A control method and technology of paper cups, applied in the direction of liquid tightness measurement using liquid/vacuum, can solve the problems of destructive damage of paper cups, failure to ensure qualified products of paper cups, etc., and achieve the effect of avoiding uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

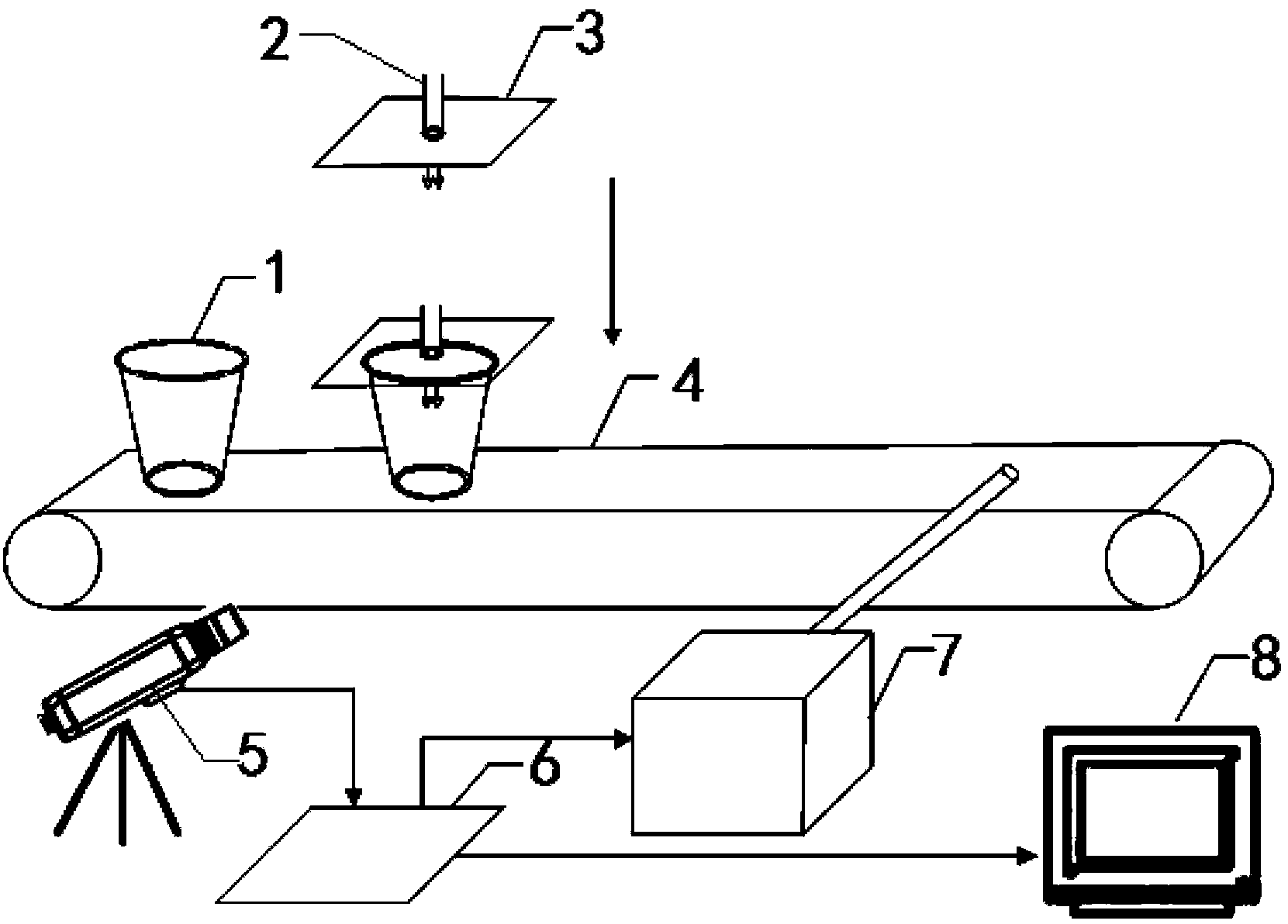

[0035] The paper cup online leak detection device is composed of a gas injection mechanism, a conveyor belt 4, an infrared thermal imager 5 and a monitor 8. The paper cup 1 to be detected is transported to the bottom of the gas injection mechanism by the conveyor belt 4 in an intermittent flow mode, and the infrared thermal imager 5 is placed on the side of the conveyor belt 4 to collect the infrared image of the paper cup 1. The monitor 8 is connected to the infrared thermal imager 5 to display the image of the infrared image. Such a leak detection device can manually observe whether there are unqualified paper cups 1. Low device cost and reliable operation.

[0036] The air injection mechanism is arranged above the conveyor belt 4, including a pressure plate 3 for covering the opening end of the paper cup 1, an air injection pipe 2 passing through the pressure plate 3 to inject hot air into the paper cup 1, and a telescopic unit connecting the pressure plate 3 and the air inj...

Embodiment 2

[0039] The paper cup online leak detection device is composed of an air injection mechanism, a conveyor belt 4, an infrared thermal imager 5, a controller 6 and a defective product rejection mechanism 7, and the paper cup 1 to be detected is transported to the gas injection mechanism by the conveyor belt 4 in an intermittent flow mode Below, the thermal imaging camera 5 is placed on the side of the conveyor belt 4 to collect the infrared image of the paper cup 1, the controller 6 is connected to the thermal imaging camera 5 to receive the image signal, and the defective product removal mechanism 7 is connected to the controller 6 to receive the control The unqualified products are eliminated after the rejecting signal of the controller 6. This detection method of automatically removing the unqualified products through the controller 6 has high working effect, strong reliability, and reduces work intensity.

[0040] In addition, the controller 6 can also be connected with a moni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com