Early weak fault diagnosis method for rolling bearings

A rolling bearing and fault diagnosis technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of different background noise frequency structure information coverage submerged, affecting the diagnosis results and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention is described in more detail below in conjunction with accompanying drawing example:

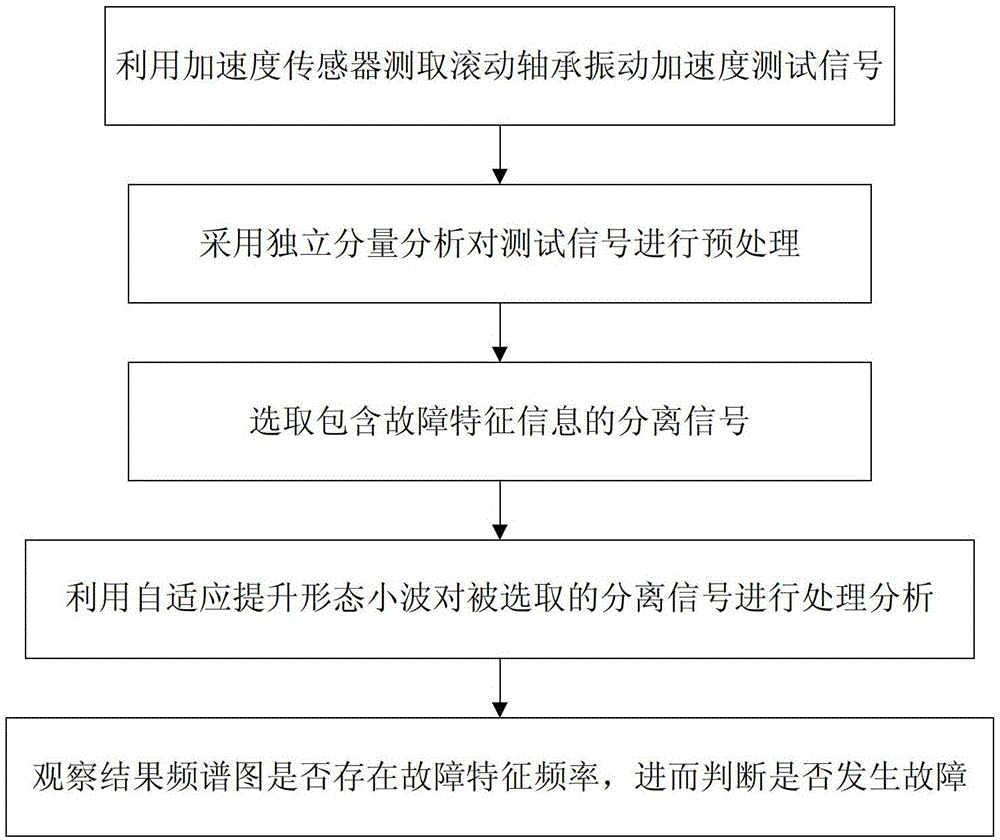

[0058] combine Figure 1~5 , the present invention comprises the following steps:

[0059] 1) Use the acceleration sensor to measure the rolling bearing to obtain the vibration acceleration test signal. The vibration acceleration test signals of the three channels of the present invention are respectively picked up by acceleration sensors installed on the base, the driving end and the output end of the casing.

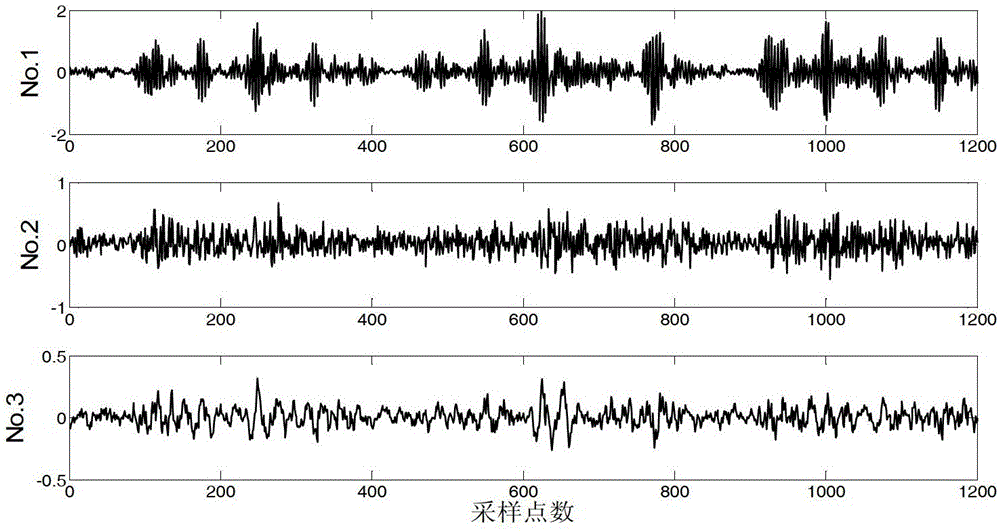

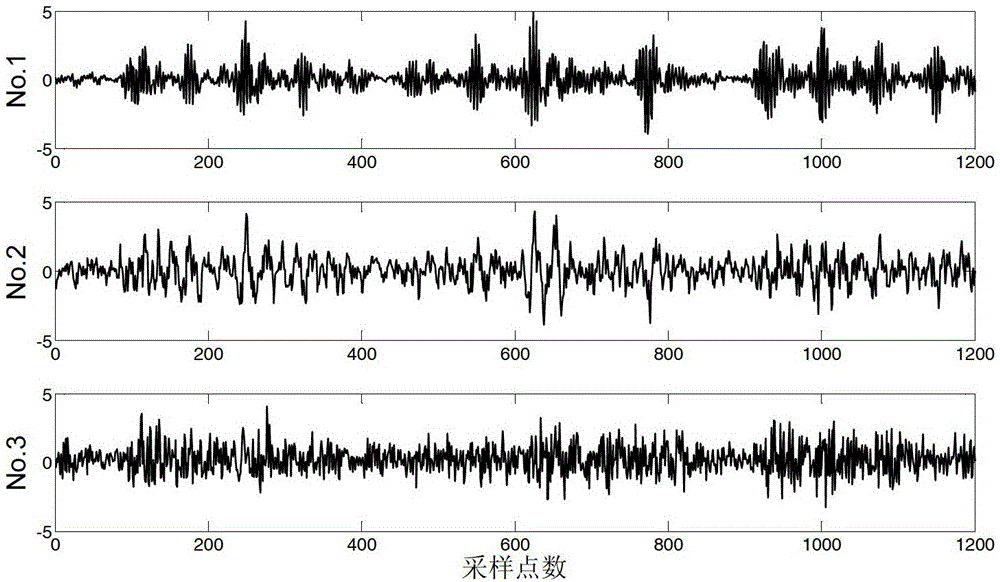

[0060] 2) Independent component analysis is used to preprocess the vibration acceleration test signal to realize the separation of the vibration source signal. The present invention adopts the improved FastICA method to decouple and separate the vibration acceleration test signal, specifically comprising the following steps:

[0061] 2.1) De-mean and whiten the vibration acceleration test signal z-matrix;

[0062] 2.2) Initialize the random weight vect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com