CAD/CAM/CNC closed-loop control method based on dynamic feature model

A dynamic feature, closed-loop control technology, applied in the direction of program control, computer control, comprehensive factory control, etc., can solve the problem of not affecting the processing quality and efficiency, and achieve the effect of improving the technological level and expressing rich information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] Such as Figure 1-5 shown.

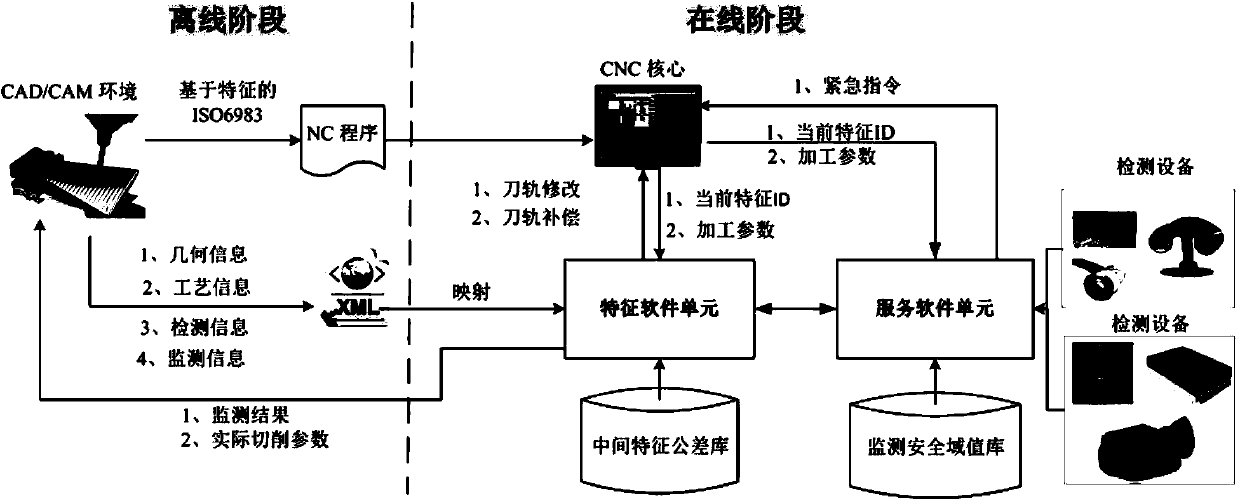

[0031] A CAD / CAM / CNC closed-loop control method based on dynamic feature model, its framework and flow chart are as follows figure 1 As shown, it includes the following steps:

[0032]First, define the geometry information, process information XML file format, and define the NC program format;

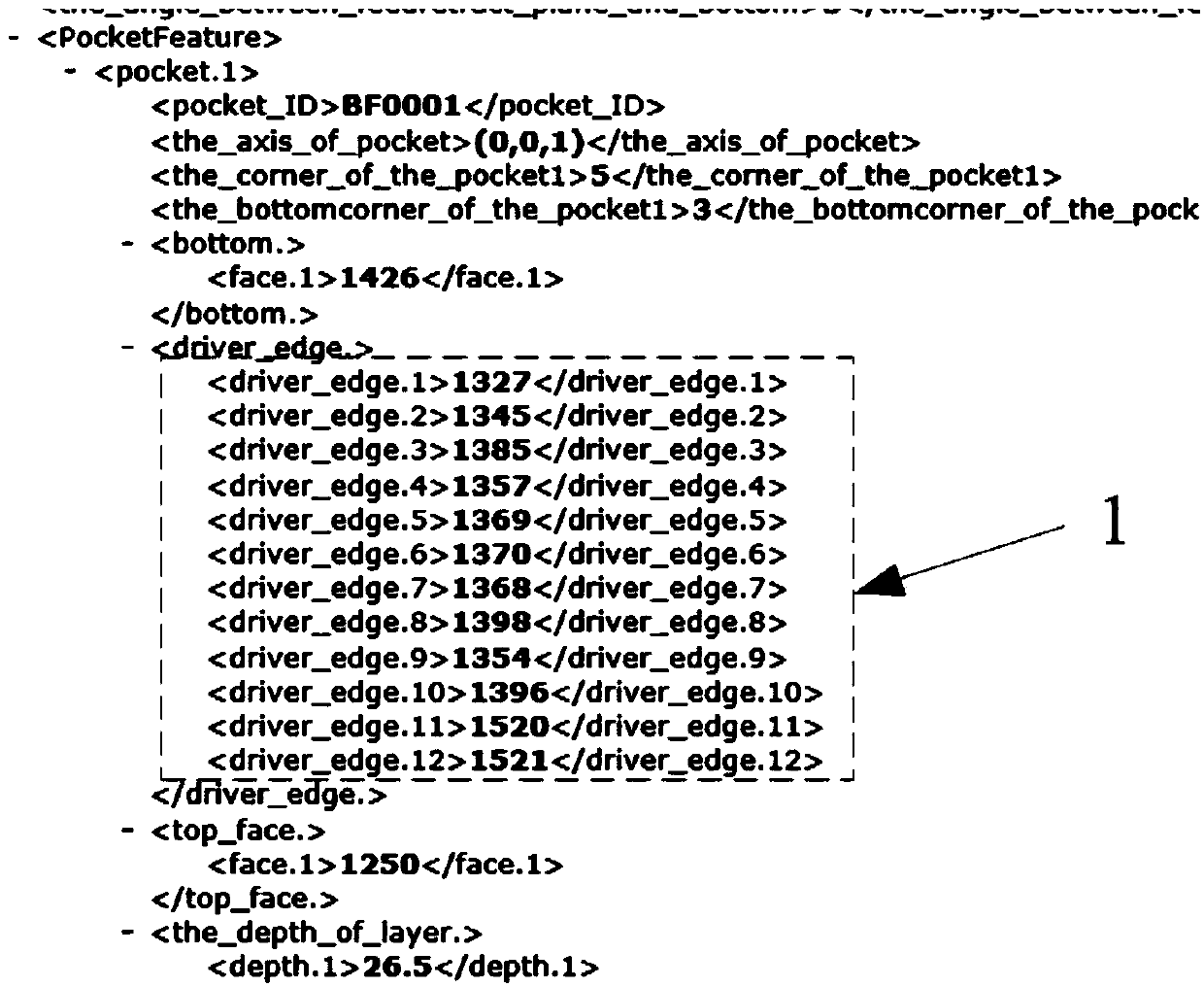

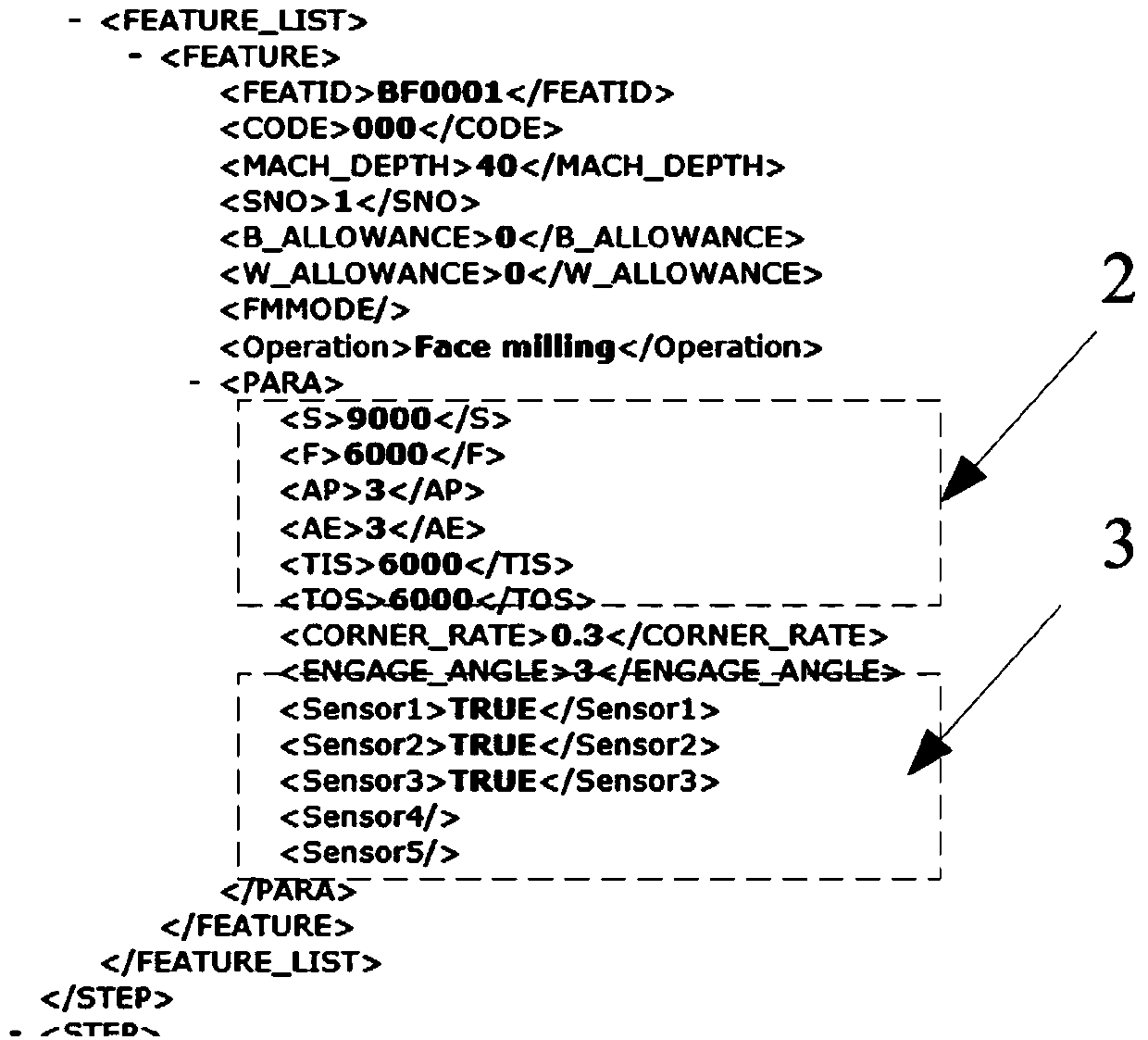

[0033] Secondly, feature recognition is carried out in the CAD / CAM software environment, the geometry and attribute information of the processing features are extracted, and then the process decision is made, and then the feature-based NC programming is carried out based on the feature recognition results and process decision results, and the processing operation of the processing features The driving geometry, attribute information, and process information are output to the corresponding XML files, and the tool path inform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com