A laser grating positioning system for rail moving equipment

A technology of mobile equipment and positioning system, applied in the direction of control using feedback, can solve the problems of poor positioning accuracy and reliability, high price, and achieve the effect of high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

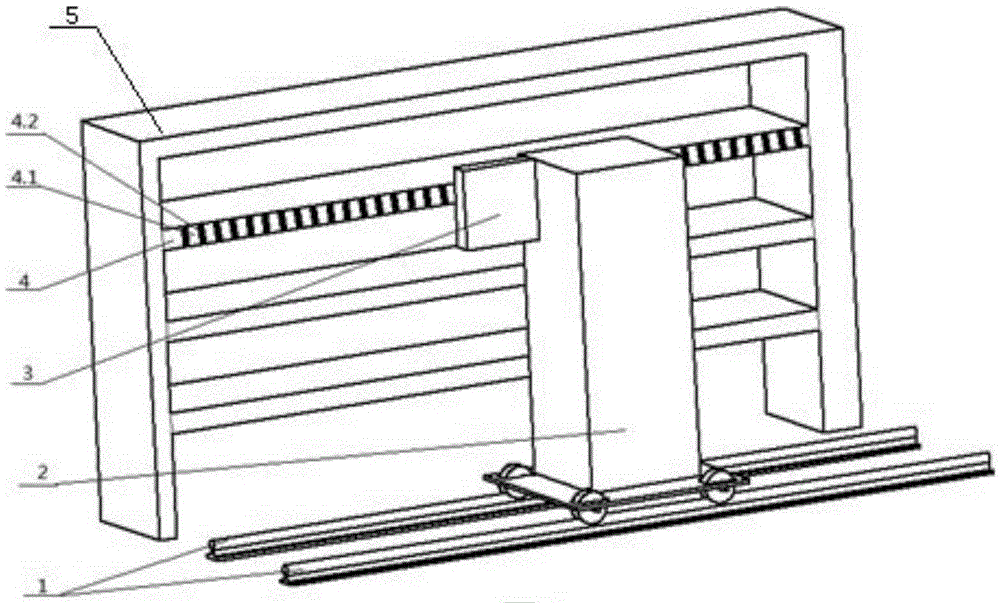

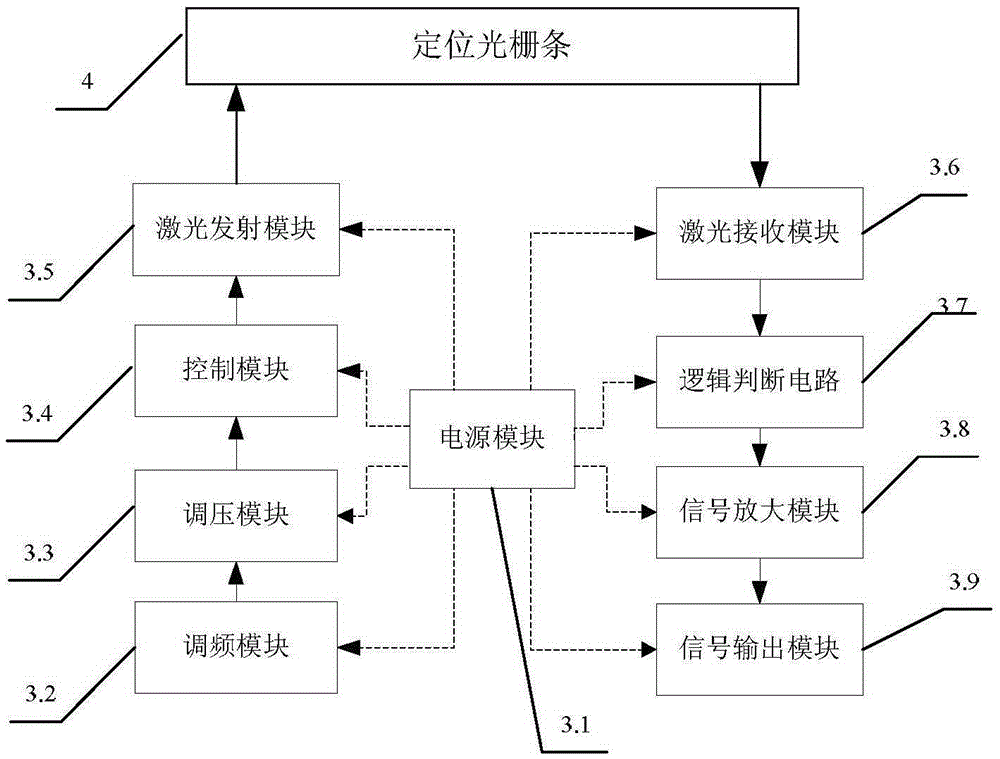

[0037] A laser grating positioning system for rail mobile equipment, including a moving guide rail 1, a mobile device 2, a laser emitting and receiving module 3, and a positioning grating bar 4 (see figure 1 ), the motion guide rail 1 is used to provide the motion constraint and motion trajectory of the mobile device; the bottom of the mobile device 2 is installed on the motion rail and moves left and right along the motion rail; the laser emitting and receiving module 3 is fixed on On the mobile device 2, it is used to emit laser light and receive reflected laser signals; the positioning grating bar 4 is installed on a fixed object frame 5 (such as a shelf, a bookcase and a medicine cabinet, etc.) and form the reflected laser signal.

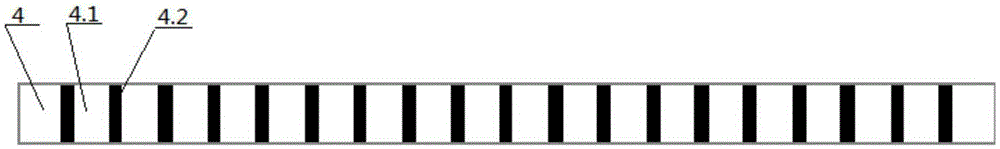

[0038] The positioning grating strips 4 are alternately arranged in areas I 4.1 and II 4.2 (see figure 2); said area I4.1 is a diffuse reflection area that does not absorb light, and this area I4.1 is coated with a diffuse reflection material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com