Manufacturing method of molybdenum granulated powder and molybdenum granulated powder

A manufacturing method and technology of granulated powder, applied in the manufacture of molybdenum granulated powder and the field of molybdenum granulated powder, to achieve the effect of excellent apparent density and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

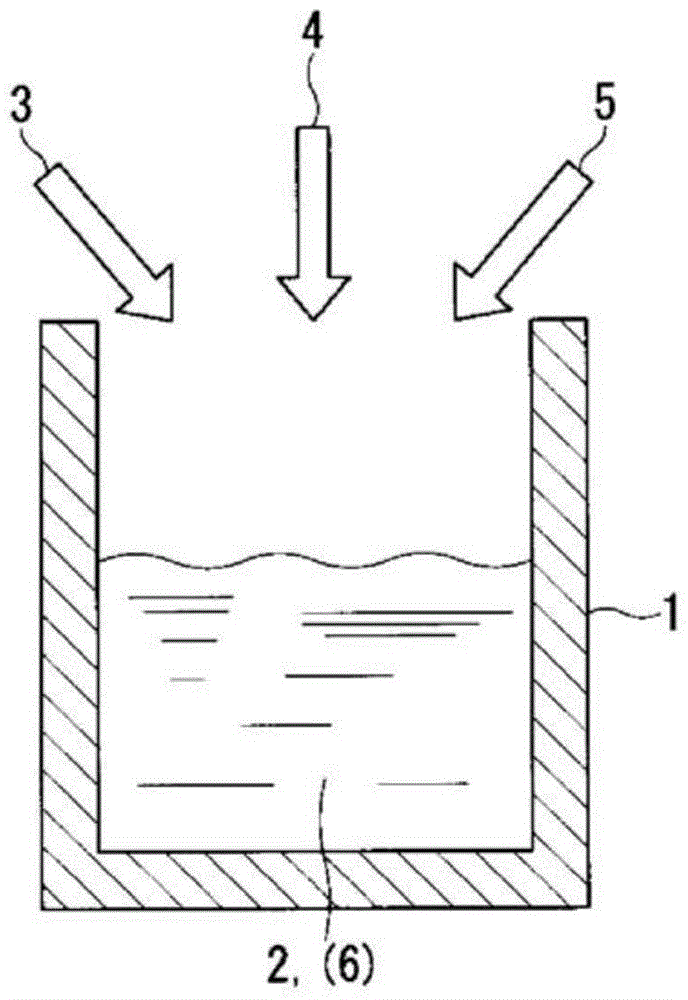

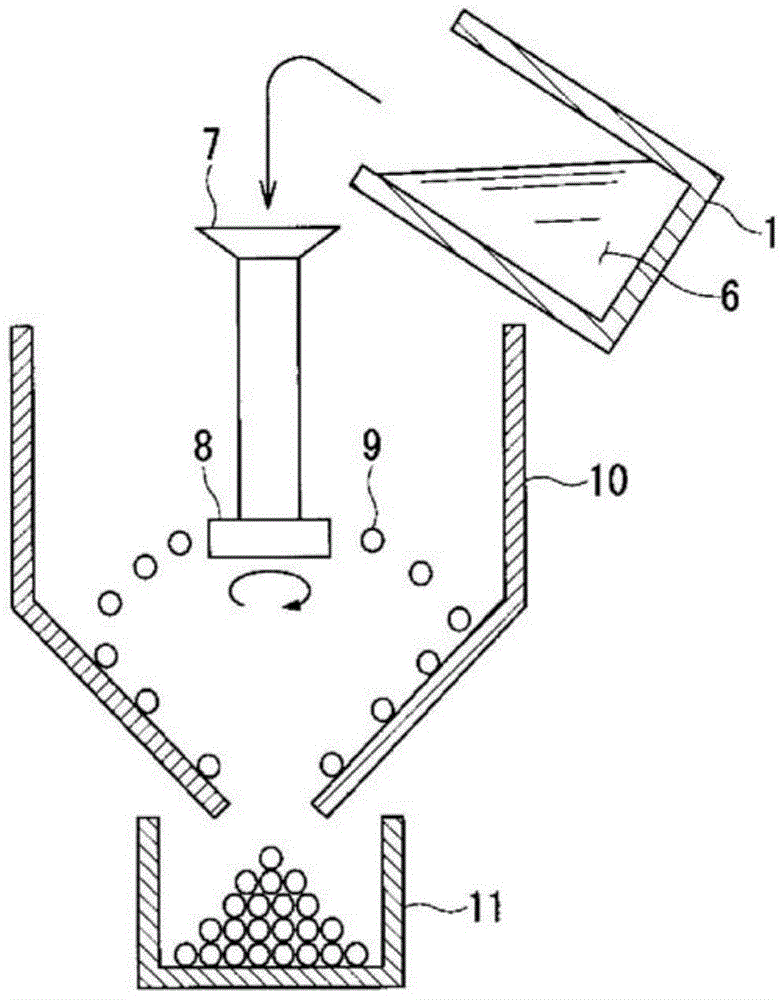

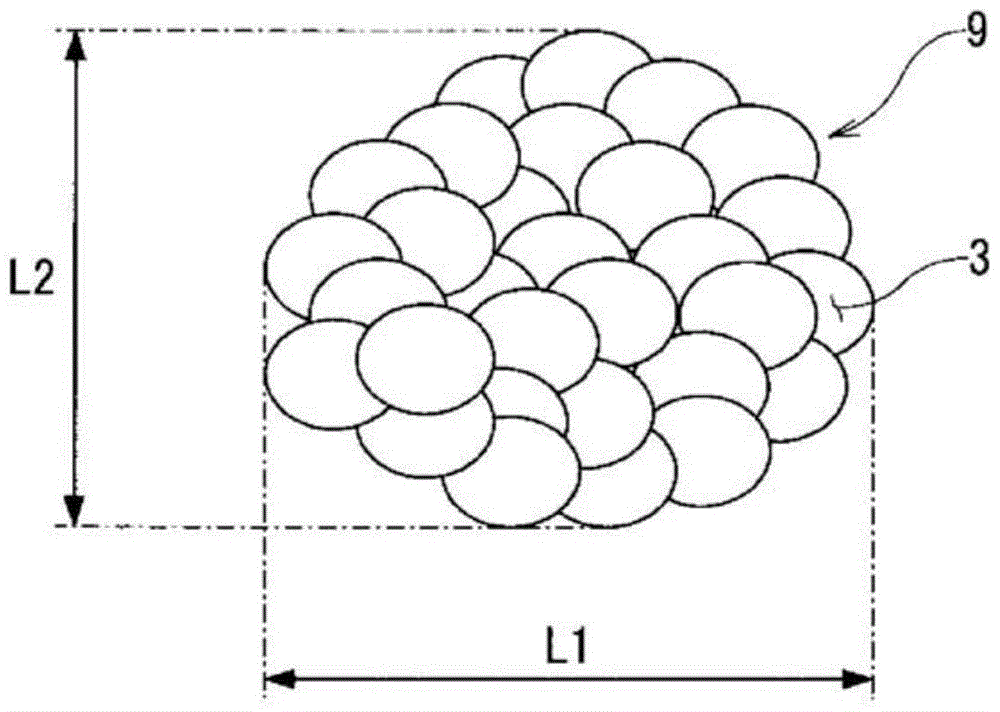

Method used

Image

Examples

Embodiment 1~5 and comparative example 1~2)

[0072] Prepare molybdenum powder (purity: 99.9% or more), polyvinyl butyral (PVB) powder as a binder, and ethanol. Ethanol was poured into a stainless steel container, and the polyvinyl butyral powder was added with stirring at room temperature to dissolve all the added polyvinyl butyral powder. It was confirmed that when the polyvinyl butyral powder was completely dissolved, it became a translucent solution. Then, a total of 40 kg of molybdenum powder was added at a time of 1 to 2 kg. When stirring the molybdenum powder, ethanol was added as necessary to the insufficient part due to the evaporation of ethanol. The molybdenum-containing solution using polyvinyl alcohol powder as a binder was set as Examples 1-5.

[0073] The conditions in the adjustment step of the conventional molybdenum-containing solution are shown in Table 1 below.

[0074] Table 1

[0075]

[0076] Next, using the molybdenum-containing solutions prepared in Examples 1 to 5 above, a granulation step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com