Copper foil for printed circuit

A printed circuit, copper foil technology, applied in the direction of printed circuit, printed circuit, printed circuit manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0134] (Conditions of Example 1)

[0135] The heat-resistant layer including the Ni—Co layer, the weather-resistant layer and the rust-proof layer including Zn, Ni, and Cr, and the silane coupling treatment were performed within the range of the conditions shown above. Conditions for forming a heat-resistant layer, a weather-resistant layer, and a rust-resistant layer are as follows.

[0136] 1) Heat-resistant layer (Ni-Co layer)

[0137] Current density (D k ): 5~15A / dm 2

[0138] Time: 0.05~3.0 seconds

[0139] 2) Weather-resistant layer (Zn-Ni layer)

[0140] Current density (D k ): 0.5~1.5A / dm 2

[0141] Time: 0.05~3.0 seconds

[0142] 3) Antirust layer (Cr-Zn layer)

[0143] Current density (D k ): 1~3A / dm 2

[0144] Time: 0.05~3.0 seconds

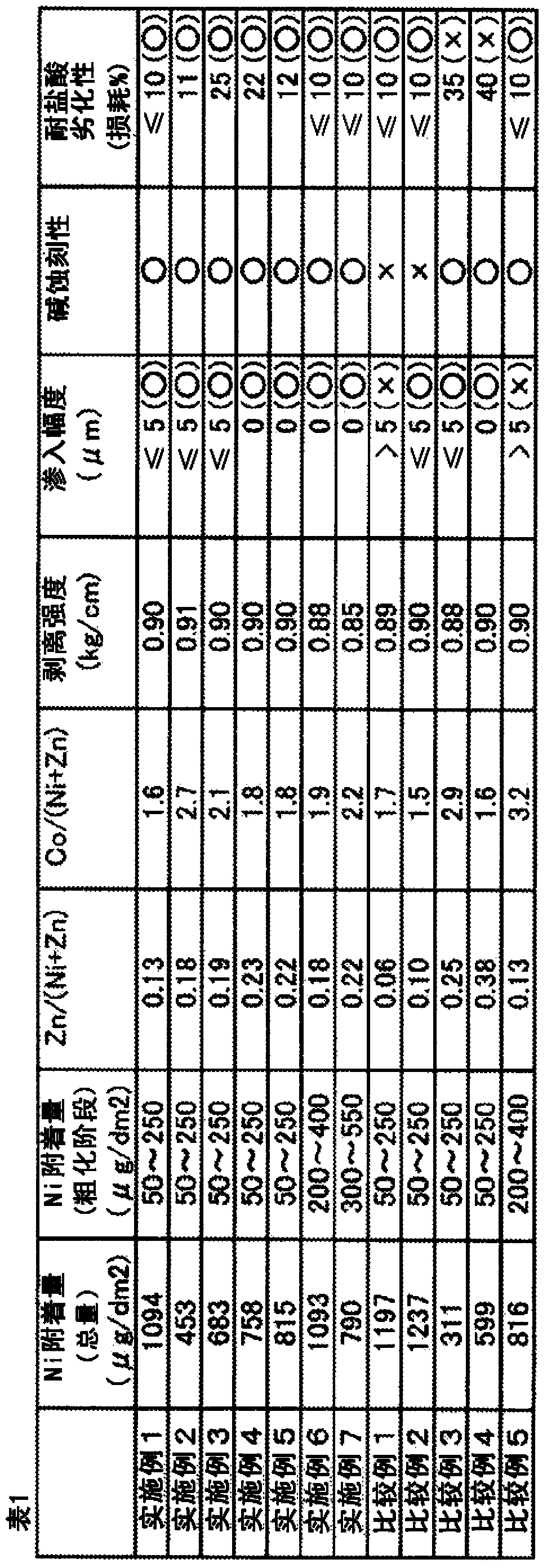

[0145] In order to make the Ni adhesion amount in all layers of roughening treatment layer, heat-resistant layer and weather-resistant layer be 1094μg / dm in total 2 The way to implement plating treatment. Zn / (Ni+Zn)=0....

Embodiment 2

[0158] As mentioned above, the amount of Ni deposited in the roughening stage is 50-250μg / dm 2 .

[0159] The heat-resistant layer including the Ni—Co layer, the weather-resistant layer and the rust-proof layer including Zn, Ni, and Cr, and the silane coupling treatment were performed within the range of the conditions shown above. Conditions for forming a heat-resistant layer, a weather-resistant layer, and a rust-resistant layer are as follows.

[0160] 1) Heat-resistant layer (Ni-Co layer)

[0161]Current density (D k ): 5~9A / dm 2

[0162] Time: 0.05~3.0 seconds

[0163] 2) Weather-resistant layer (Zn-Ni layer)

[0164] Current density (D k ): 0.05~0.7A / dm 2

[0165] Time: 0.05~3.0 seconds

[0166] 3) Antirust layer (Cr-Zn layer)

[0167] Current density (D k ): 1~3A / dm 2

[0168] Time: 0.05~3.0 seconds

[0169] The total amount of Ni attached to all layers of the roughening treatment layer, heat-resistant layer, and weather-resistant layer is 453 μg / dm 2 , ...

Embodiment 3

[0173] As mentioned above, the amount of Ni deposited in the roughening stage is 50-250μg / dm 2 .

[0174] The heat-resistant layer including the Ni—Co layer, the weather-resistant layer and the rust-proof layer including Zn, Ni, and Cr, and the silane coupling treatment were performed within the range of the conditions shown above. Conditions for forming a heat-resistant layer, a weather-resistant layer, and a rust-resistant layer are as follows.

[0175] 1) Heat-resistant layer (Ni-Co layer)

[0176] Current density (D k ): 6~11A / dm 2

[0177] Time: 0.05~3.0 seconds

[0178] 2) Weather-resistant layer (Zn-Ni layer)

[0179] Current density (D k ): 0.05~0.7A / dm 2

[0180] Time: 0.05~3.0 seconds

[0181] 3) Antirust layer (Cr-Zn layer)

[0182] Current density (D k ): 2~4A / dm 2

[0183] Time: 0.05~3.0 seconds

[0184] The total amount of Ni attached to all layers of the roughening treatment layer, heat-resistant layer, and weather-resistant layer is 683 μg / dm 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com