Tea enzyme-deactivating and baking streamline system utilizing microwave to heat and dry

An assembly line and microwave technology, applied in the field of tea greening and drying assembly line system, can solve the problems of easy generation of coke leaves, long production cycle, huge equipment, etc., and achieve the effect of rapid greening and improving tea quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

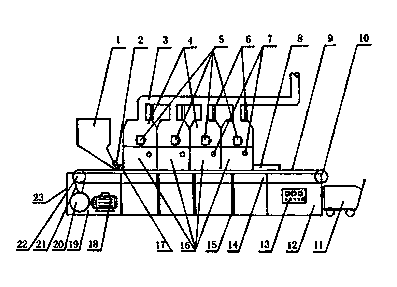

[0009] As shown in the accompanying drawings, the tea greening and drying assembly line system using microwave heating and drying includes a feeding funnel 1, a uniform discharge device 2, an exhaust pipe 3, a microwave bin 4, a microwave magnetron generator 5, and a suction Pipe 6, suction port 7, discharge attenuation bin 8, conveyor belt 9, transmission auxiliary shaft 10, finished car 11, control cabinet 12, external control panel 13, transmission platform 14, outrigger 15, finishing drying chamber 16, feeding The attenuation chamber 17, the motor 18, the electric chamber 19, the reducer 20, the transmission belt 21, the transmission main shaft 22, and the device body 23 are composed; the device body 23 is provided with a transmission platform 14, a finishing and drying chamber 16, a microwave chamber 4 and a feeding funnel 1 The upper part of the transmission platform 14 is provided with the transmission main shaft 22, the transmission auxiliary shaft 10 and the conveyor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com