Welding device of honeycomb sloped tube

A welding device and a technology for a honeycomb inclined tube, which is applied in the field of welding between plastic parts, can solve the problems of complex structure, falling apart of the inclined tube, low production efficiency, etc., and achieve the effect of simple overall structure, improved production efficiency and good welding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

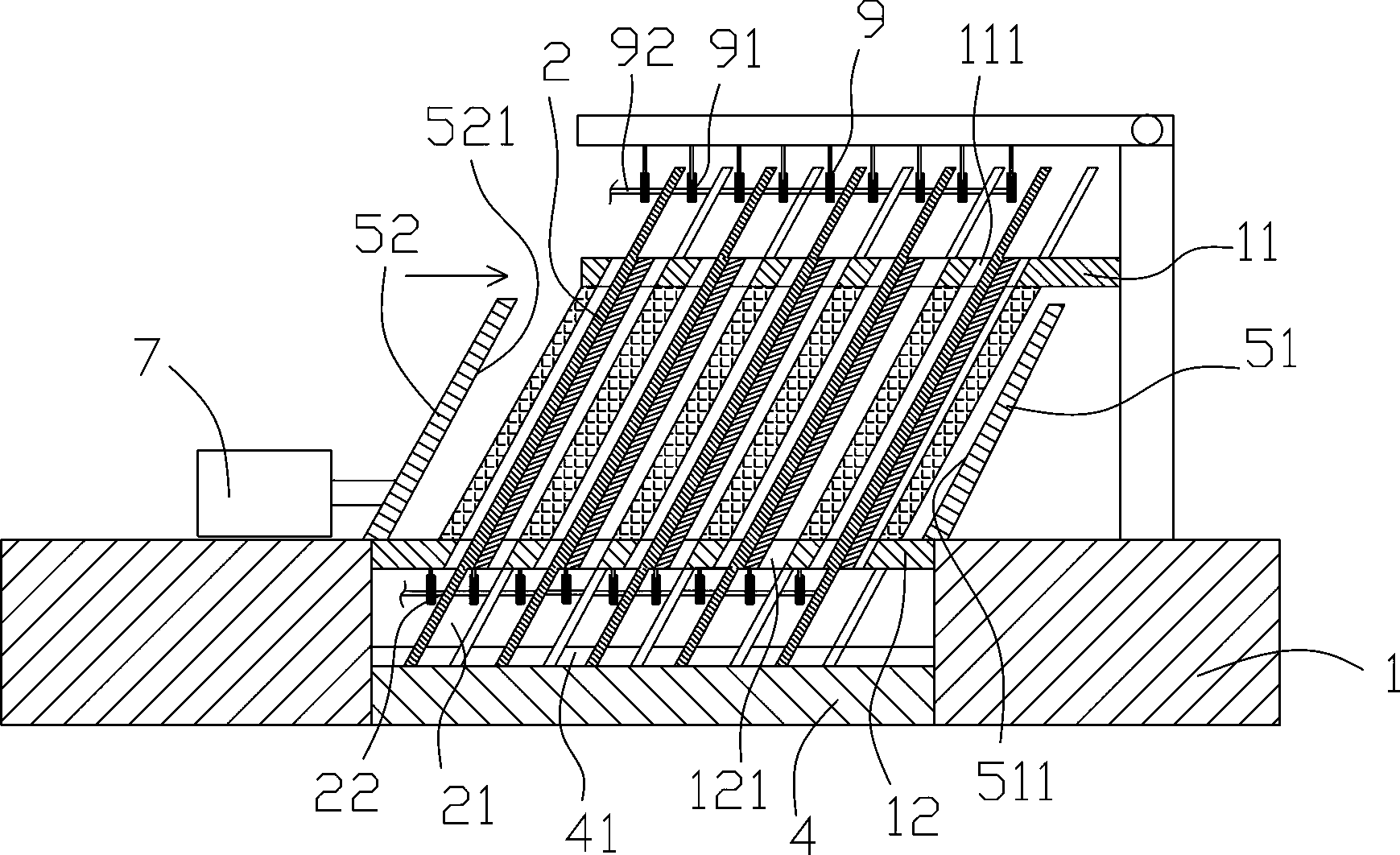

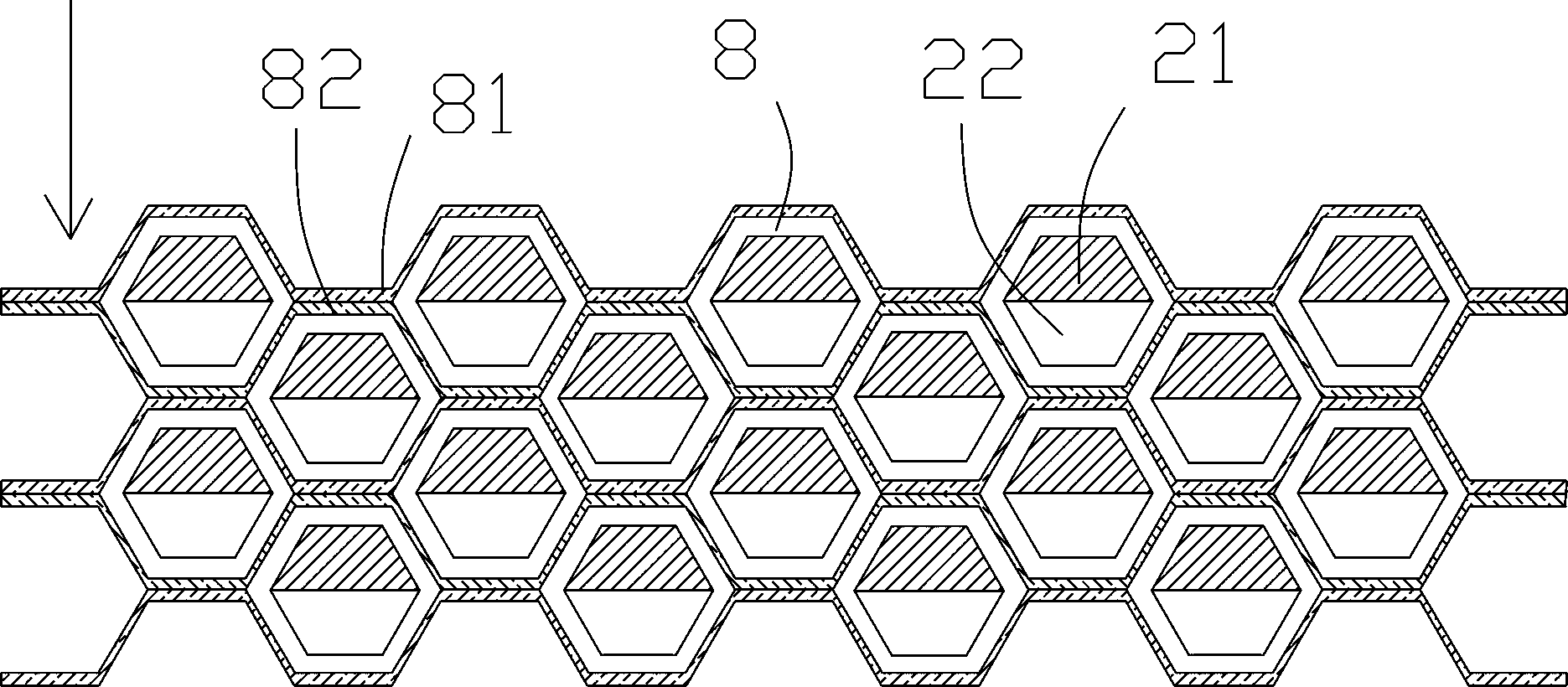

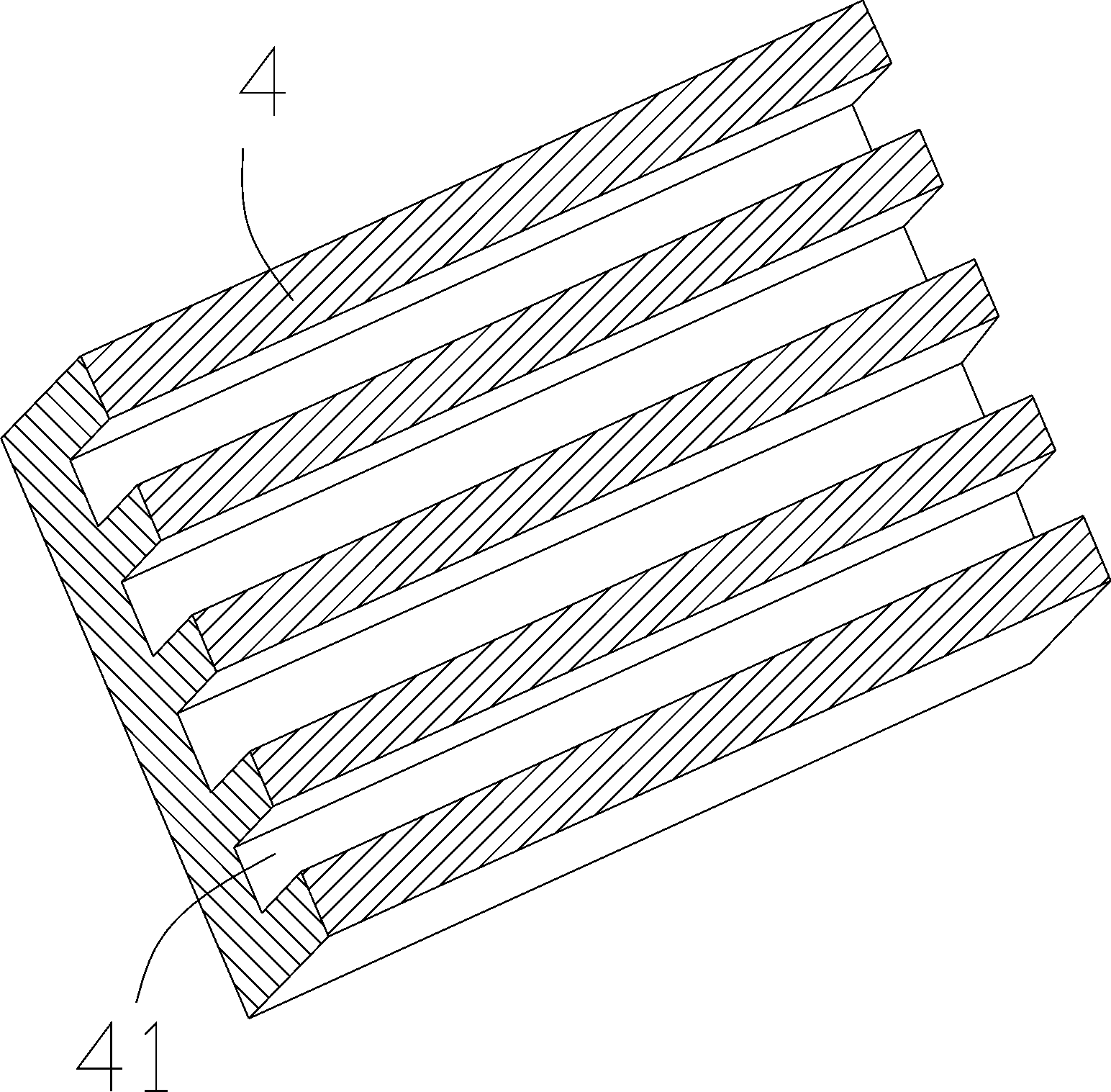

[0022] Such as Figure 1-5 As shown, the arrows in the figure all indicate the direction of movement. A welding device for a honeycomb inclined tube includes a heating component, an upper support template 11 and a lower support template 12 for supporting the heating component, a bracket 1 and a support template 12 located below the lower support template 12. The bottom plate 4, the heating components include high-frequency heating rods 2 arranged in a honeycomb shape, each heating rod 2 includes a heating surface 21 on the front side and a cold surface 22 on the rear side, and the heating surface 21 is a high-frequency heating surface , it can be heated instantly after being ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com