Weight-resistant tire for bicycle

A bicycle and heavy-duty technology, applied in bicycle tires, bicycles, two-wheeled bicycles, etc., can solve the problems of limited resistance to external force, poor puncture resistance, and burning edge of tires, so as to enhance the ability to resist external forces, increase The beauty of the appearance, the effect of avoiding friction and burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

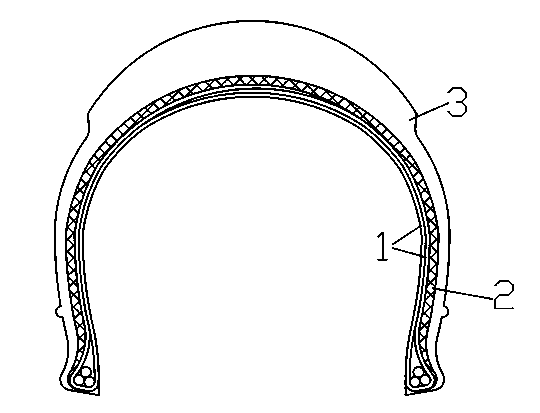

[0017] figure 1 It is a cross-sectional view of a heavy-duty bicycle tire of the present invention; as shown in the figure, a heavy-duty bicycle tire of the present invention includes a tire body, and the tire body is composed of a high-density layer 3, a reinforcing layer 2 and a tread layer 1 sequentially from the inside to the outside , the high-density layer 3 and the reinforced layer 2 surround in turn to form a circle, the reinforced layer 2 is placed on the outer periphery of the high-density layer 3, the tread 1 is placed on the outer periphery of the reinforced layer 2, and the tread layer 1 is a 68SA rubber layer , the thickness is increased by 5mm; the reinforced layer 2 is a nylon interwoven cord layer; the high-density layer 3 is folded and overlapped at the center; adopting the technical scheme of the present invention, the tread layer 1 is a 68SA rubber layer, and the thickness is increased by 5mm, which avoids road surface damage Foreign objects such as glass a...

Embodiment 2

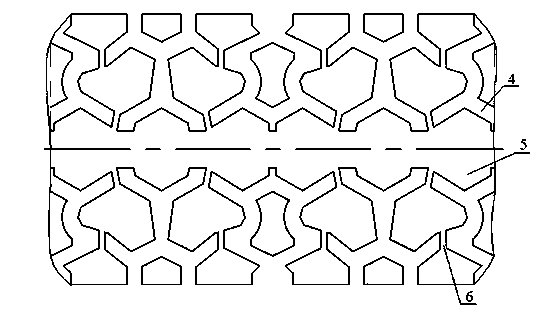

[0019] figure 2 for figure 1 Shown is a partial schematic view of the tread layer of a heavy-duty bicycle tire of the present invention. The surface of the tread layer 1 of the tire body is symmetrically provided with multiple groups of block patterns, and each group of block patterns is composed of four strip-shaped ribs 4 and six polygons. It consists of pattern blocks 5; grooves 6 are formed between adjacent polygonal pattern blocks 5. The tire tread layer 1 is provided with polygonal pattern blocks 5, which has a good anti-skid effect in rainy days and also increases the aesthetic feeling of its appearance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com