Automatic applicator of protective films

An automatic sticking and protective film technology, applied in the field of mechanical equipment, can solve the problems of increasing book processing procedures, heavy manual sticking workload, and inconsistent mounting positions, achieving strong market promotion prospects, strong market development potential, and reducing The effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

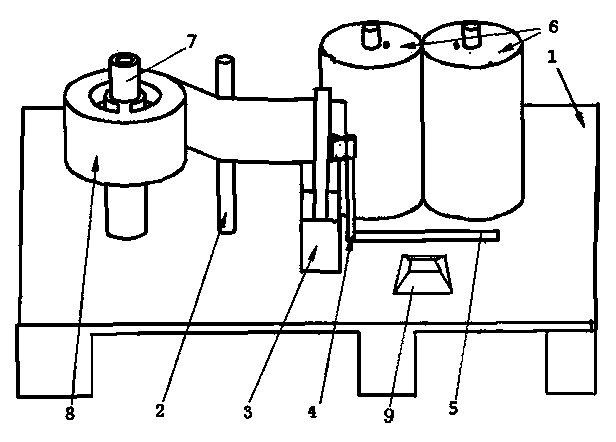

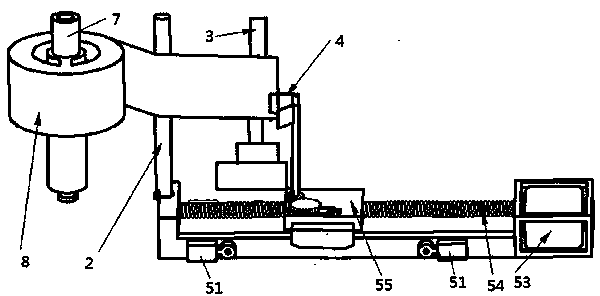

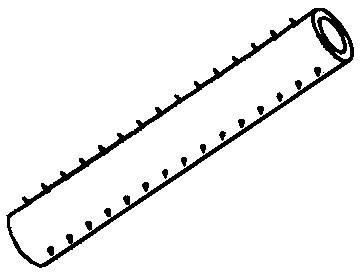

[0022] like figure 1 , figure 2 As shown, the protective film automatic sticking machine includes a protective film guide column 7, a protective film positioning rod 2, a cutter 3, a clamper 4, a reset switch 9, a pair of silicon rubber rollers 6 and a section of guide rail 5 that are close together, The holder 4 for clamping the protective film 8 is set on the guide rail 5 and can move along the guide rail 5. The protective film positioning rod 2 and the silicone rubber roller 6 are all set on the guide post fixed on the platen 1 through the bearing and move along with it. The guide post rotates synchronously, and the cutter 3 is a cylinder whose surface is covered with spikes (see image 3 ), fixed on the platen 1 near the end of the guide rail 5 of the protective film, a pair of silicon rubber rollers 6 are arranged in parallel on one side of the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com