Vehicle-mounted automatic material supply device

A supply device, vehicle-mounted technology, applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of increased repetitive work time, assembly errors, product reassembly, etc., to reduce the limit of line layout, The effect of shortening the length of the line body and reducing the complexity of the steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

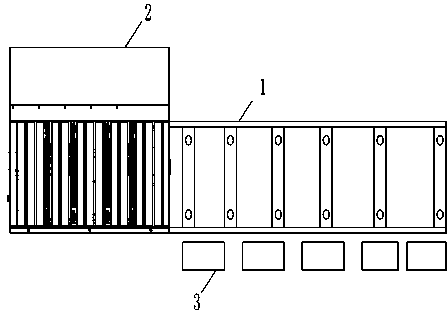

[0015] Such as figure 1 , figure 2 As shown, the vehicle-mounted automatic material supply device includes a conveying trolley 2 and a conveying track 1. A movable conveying trolley 2 is arranged on the conveying track 1. When the conveying trolley 2 moves from one end of the conveying track 1 to the other end, the conveying trolley 2 is a feeding device. When the conveying trolley 2 returns to the initial position from the conveying track 1, the conveying trolley 2 is a loading and unloading device, and several groups of single-work station platforms 3 are arranged on the side of the conveying track 1;

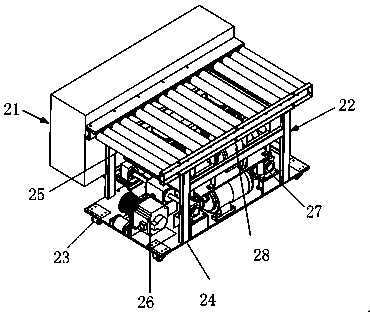

[0016] The conveying trolley 2 includes a control electric box 21 and a conveying device 22, the side of the conveying device 22 is fixed with a control electric box 21, the conveying device 22 includes a frame 24, and a servo motor 26 is arranged inside the frame 24, and the servo motor 26 conveys through a chain Device 28 is driven and connected with the conveying rail wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com