Carbon filter water quality advanced processing control method and device thereof based on dynamic PID adjusting technology

A technology of advanced treatment and control method, which is applied in adsorption water/sewage treatment, electrical program control, program control in sequence/logic controllers, etc., and can solve the problem of not ensuring that the drinking water quality fully and stably meets the national standard, etc. To achieve the effect of improving the efficiency of water treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

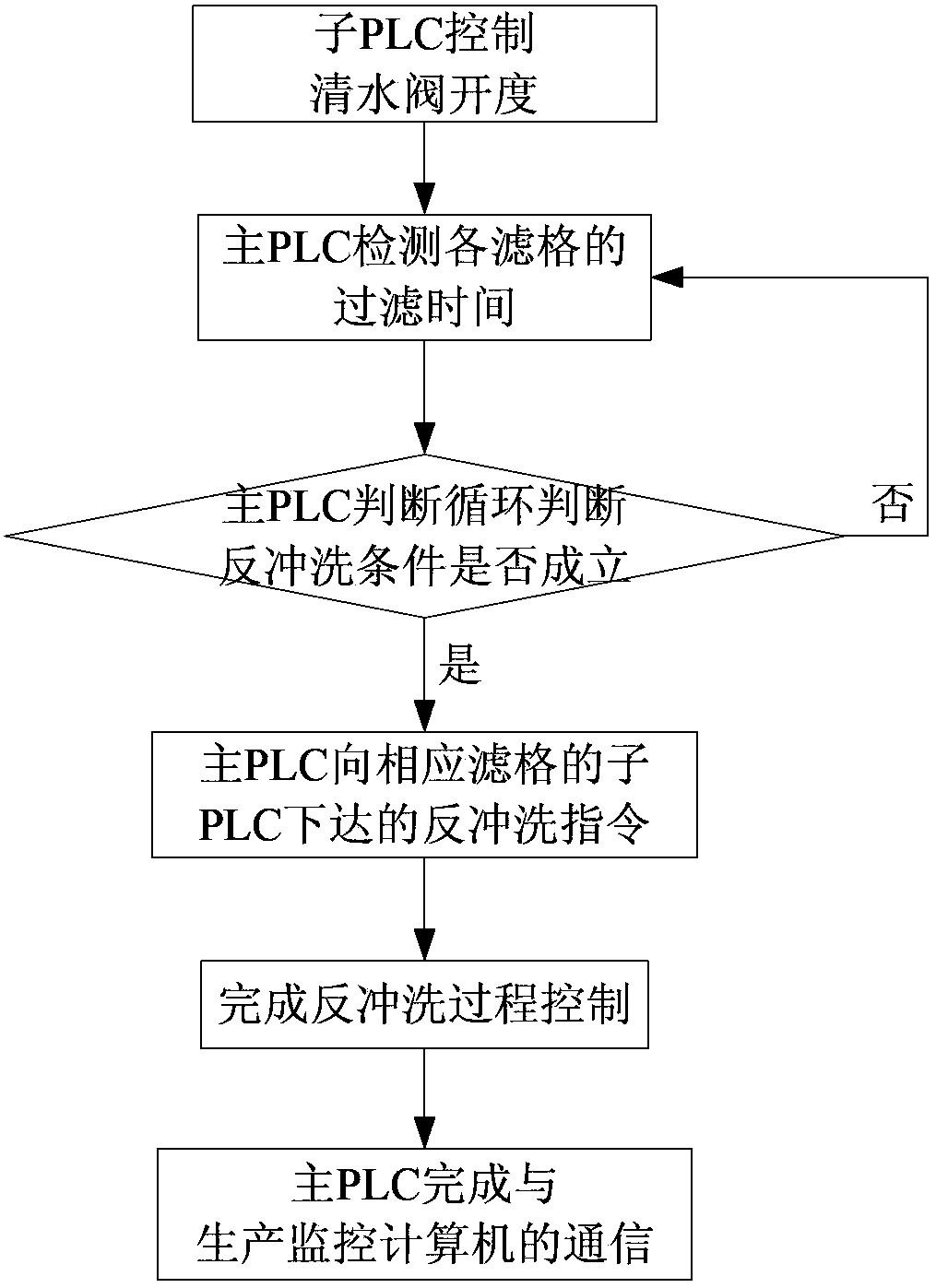

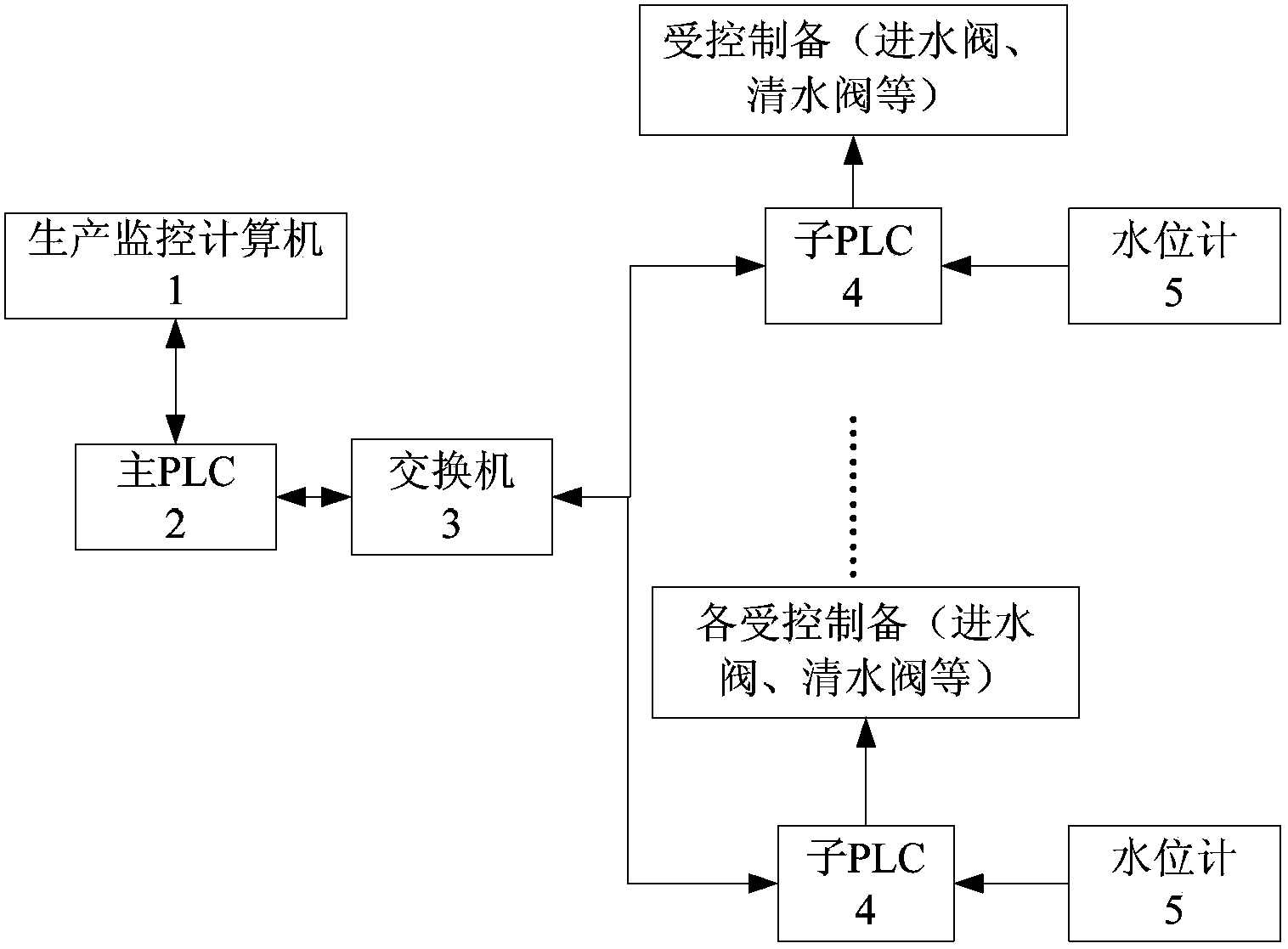

[0036] Such as figure 1 As shown, a carbon filter water quality advanced treatment control method based on dynamic PID adjustment technology, the method includes the following steps:

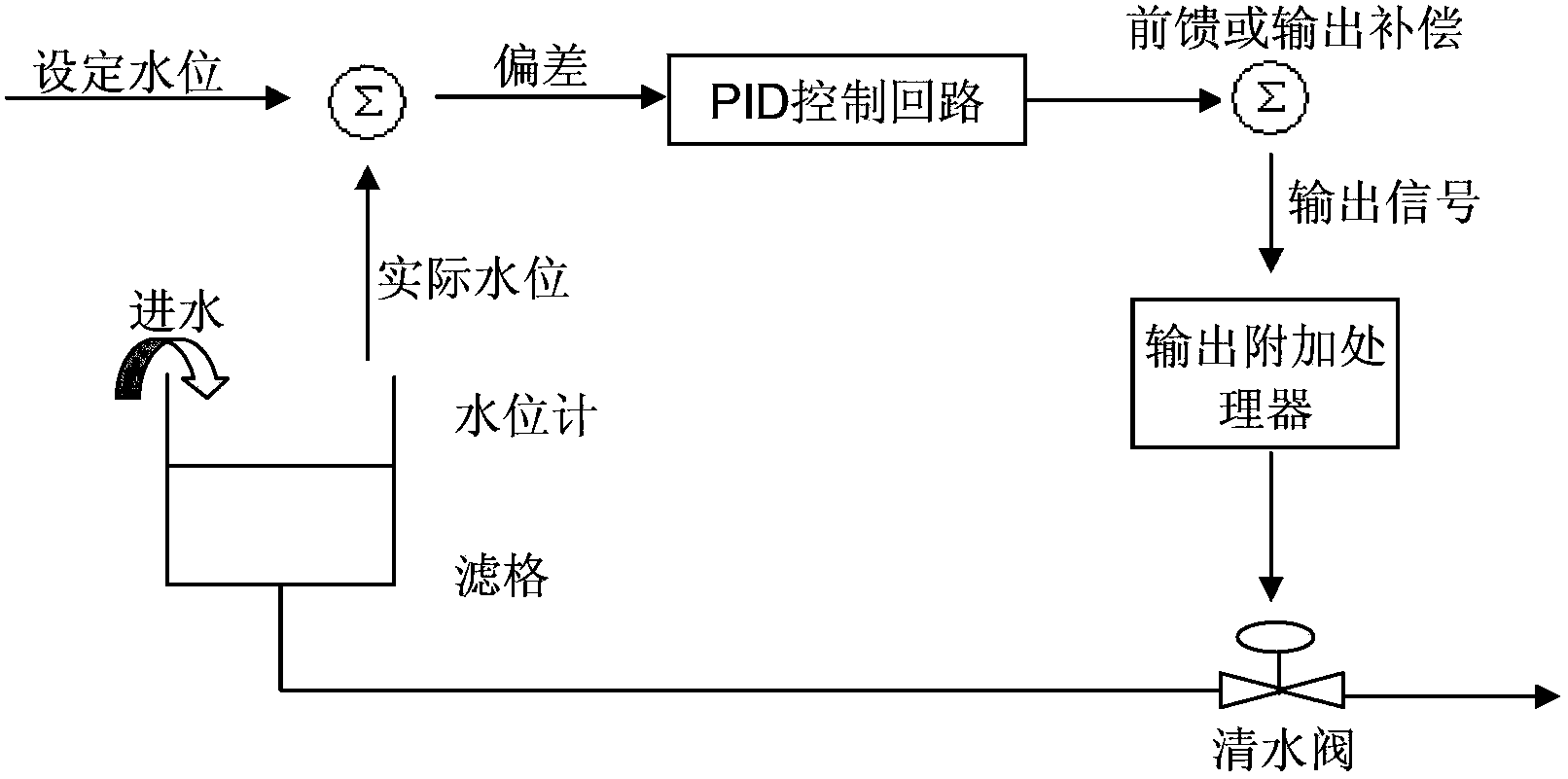

[0037] 1) The sub-PLC of each filter grid in the filter tank automatically adjusts the opening of the clear water valve to implement constant water level filtration of the filter grid, such as figure 2 As shown, the specific steps of filter grid constant water level filtration are as follows:

[0038] 11) The water level gauge and differential pressure transmitter transmit the water level of the filter grid and the opening degree signal of the clean water valve to the sub-PLC of each filter grid;

[0039] 12) The sub-PLC calculates the deviation between the received water level and the set water level, and after calculating through the PID control loop in the sub-PLC, transmits the output signal to the output additional processor in the sub-PLC;

[0040] 13) The output additional processor pr...

Embodiment 2

[0056] refer to Figure 1 to Figure 3 As shown, a carbon filter water quality advanced treatment control method and device based on dynamic PID adjustment technology, the main steps and device of the method are the same as in Example 1, the difference is that the specific steps of the backwashing process in this embodiment are as follows :

[0057] Preparation stage: After the sub-PLC accepts the backwash command issued by the main PLC, close the water inlet valve, open the sewage valve, and close the clean water valve when the water level of the filter tank is lowered to the drainage level;

[0058] 22) Air flushing stage: the main PLC starts a blower, the sub-PLC opens the air flushing valve, and the air flushes for 2.5 minutes;

[0059] 23) Air-water combined backwash stage: the main PLC restarts a blower and a flushing pump, and the sub-PLC opens the water flushing valve at the same time to perform air-water combined backwash, and the combined air-water backwash time is 6...

Embodiment 3

[0064] refer to Figure 1 to Figure 3 As shown, the carbon filter water quality advanced treatment control method and device based on the dynamic PID adjustment technology of the present invention are applied to the advanced treatment system of Shanghai Yuanjiang Water Plant.

[0065] (1. Purpose

[0066] The water supply scale of the first phase of Yuanjiang Water Plant is 300,000 tons per day. In order to further improve the quality of the factory water, the water production process of Yuanjiang Water Plant will rely on the carbon filter to rely on the strong adsorption of harmful substances by activated carbon to conduct advanced treatment of the water quality in order to Make the factory water quality meet the standard of drinking water.

[0067] (2) System features

[0068] The activated carbon filter system of Yuanjiang Waterworks includes: 6 blowers, 6 sets of flushing pumps and 6 sets of air compressors in the flushing pump room; 16 grid V-shaped filters.

[0069] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com