Novel vertical flow automatic aeration annular artificial wetland system

A technology of artificial wetland system and automatic oxygenation, which is applied in the direction of aerobic and anaerobic process treatment, sustainable biological treatment, energy wastewater treatment, etc., and can solve the problems of increasing investment in wetland system infrastructure, easy to block openings, and increased concentration , to improve water treatment efficiency, reduce land occupation, and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The implementation site, a suburb of Hefei, Anhui, was implemented in November 2012, covering an area of 5m 2 , the daily design water treatment volume is 2~2.5m 3 / d. The specific operation is as follows:

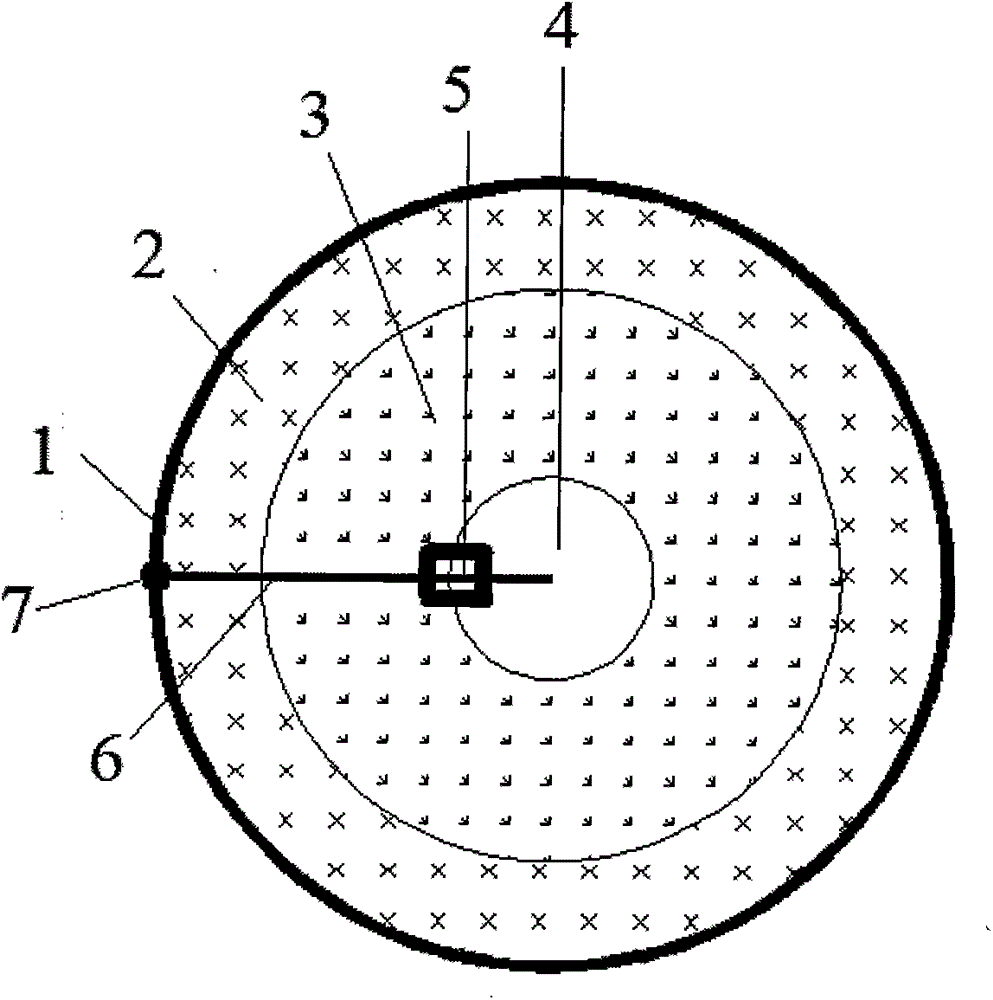

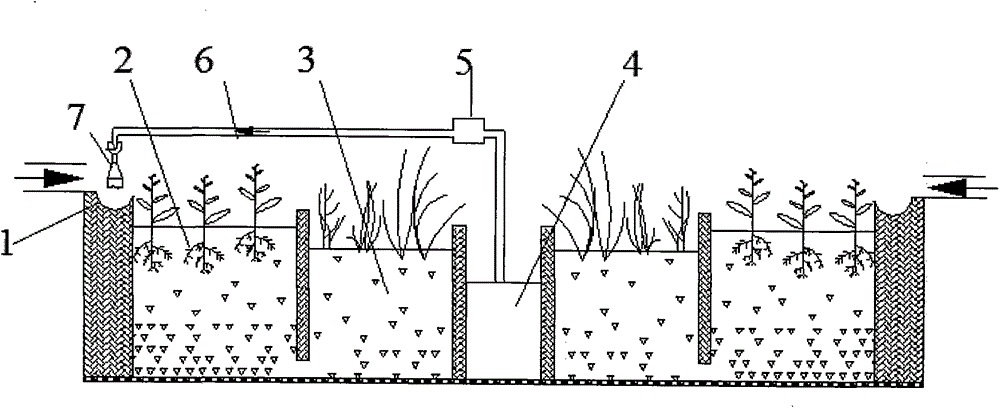

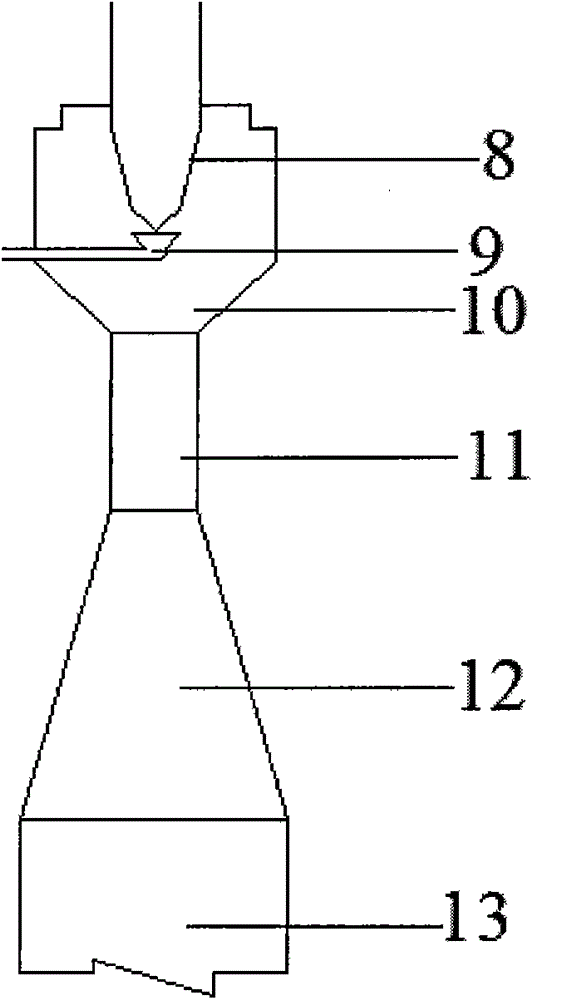

[0040] Such as figure 1 As shown, a new type of vertical flow automatic oxygenation annular constructed wetland system is: a water distribution distribution tank 1, a downstream annular pool 2 and an upward flow annular pool 3 are set to form a constructed wetland system, a sump 4 and a return pump 5 and The hollow circular flow jet 7 constitutes the process of sewage collection and secondary circulation treatment; the downstream circular pool 2, the upstream circular pool 3 and the sump pool 4 connected at the bottom form a vertical flow artificial wetland, and the bottom of the downstream circular pool 2 is connected to the upstream circular pool. The annular pool 3 communicates, and a hollow annular flow jet 7 is arranged above the sump, and is connected wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com