Automatic control method for advanced treatment of water plant

An advanced treatment, water plant technology, applied in water treatment parameter control, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of increasingly high requirements and low popularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

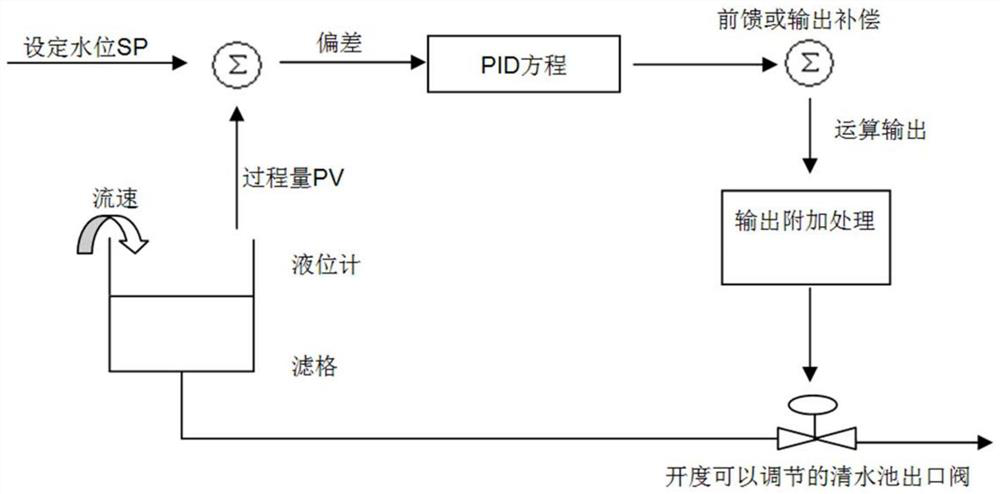

[0030] On the basis of a large number of experiments, the present invention proposes a carbon filter comprehensive control method based on the dynamic PID adjustment technology of the filtered water quality index feedback, and completes the dynamic feedback micro-control of the advanced treatment, so as to improve the full adsorption of activated carbon and improve the performance of the carbon filter The goal.

[0031] Such as figure 1 Shown, the method step stage in the specific technical scheme comprises:

[0032] (1) Control principle of activated carbon filter

[0033] ① During normal filtration, the control subsystems of each filter grid automatically adjust the opening of the clean water valve according to the water level of the filter grid, and perform filtration at a constant water level of the filter grid to ensure that the turbidity of the effluent reaches the standard.

[0034] ②The main control platform automatically detects the flushing cycle time of each filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com