Waterproof thermal-insulation board

A thermal insulation board and diglycidyl ether technology, which is applied in the field of boards, can solve the problems of poor waterproof and thermal insulation performance of the boards, and achieve good waterproof and thermal insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

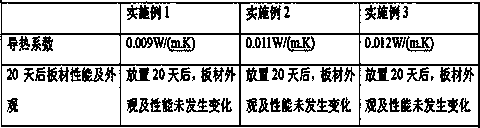

Embodiment 1

[0007] Get 26kg of polypropylene glycol diglycidyl ether, 7kg of glass wool, 4kg of naphtha, 12kg of naphthenic acid, 7kg of monoglyceride succinate, 13kg of magnesium carbonate powder, and 5kg of dibutyl maleate. Mix according to weight at 110°C under normal pressure, stir evenly with a stirring paddle, roll with a roller press after cooling to 80°C, roll with a mold after rolling, and cool to normal temperature to obtain a finished product.

Embodiment 2

[0009] The preparation method is the same as in Example 1, and the content of each component in this example is: 29 kg of polypropylene glycol diglycidyl ether, 10 kg of glass wool, 3 kg of naphtha, 9 kg of naphthenic acid, 8 kg of monoglyceride succinate, and magnesium carbonate powder 14kg, dibutyl maleate 6kg.

Embodiment 3

[0011] The preparation method is the same as in Example 1. In this example, the content of each component is 28kg of polypropylene glycol diglycidyl ether, 8kg of glass wool, 5kg of naphtha, 10kg of naphthenic acid, 7kg of monoglyceride succinate, and 7kg of magnesium carbonate powder. 14kg, dibutyl maleate is 5kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com