Waterproofing and thermal insulation construction method for building water supply and drainage and heating engineering

A construction method, water supply and drainage technology, applied in the direction of building thermal insulation materials, thermal insulation, construction, etc., can solve the problems of low construction efficiency, poor waterproof and thermal insulation effects, irregularities, etc., to achieve convenient process construction, good waterproof and thermal insulation effect, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

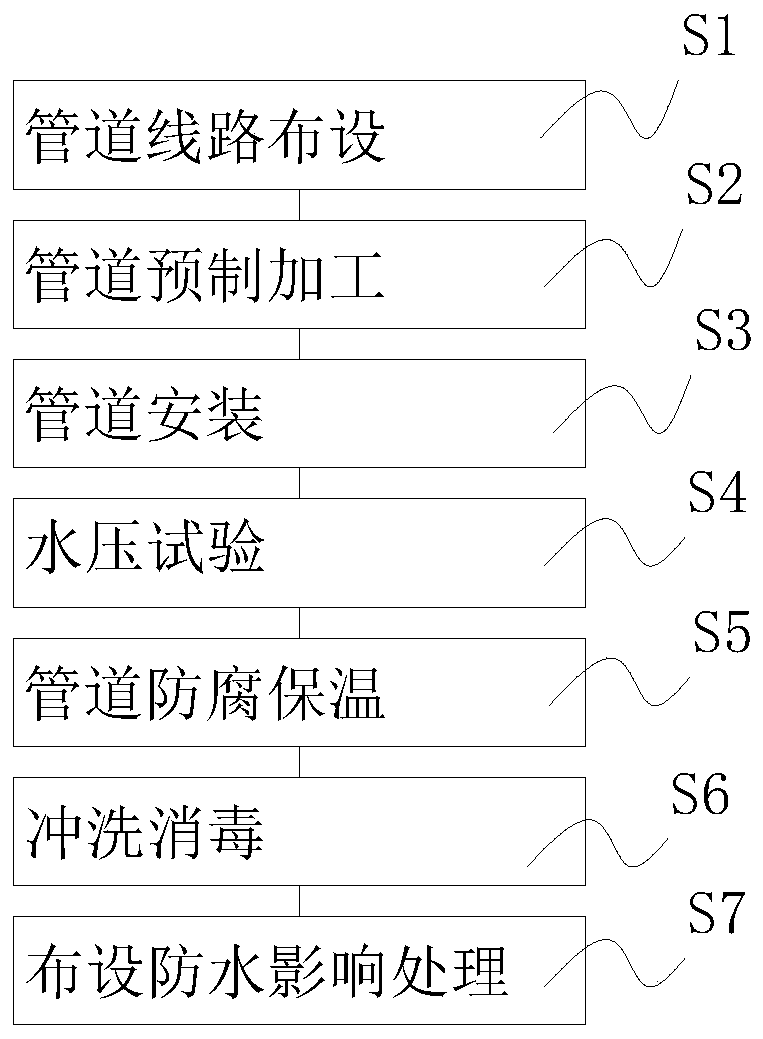

[0051] Embodiment one: refer to Figure 1~4 , a waterproof and thermal insulation construction method for building water supply and drainage and heating engineering, comprising the following steps:

[0052] S1. Pipe line layout, carry out on-site line layout layout for water supply, drainage and heating engineering pipelines according to the design;

[0053] S2. Pipeline prefabrication processing, pipeline prefabrication processing according to the pipeline line;

[0054] S3, pipeline installation;

[0055] S4. Hydrostatic test;

[0056] S5. Pipeline anti-corrosion and heat preservation;

[0057] S6, rinse and disinfect;

[0058] S7. Treatment of the impact of waterproofing.

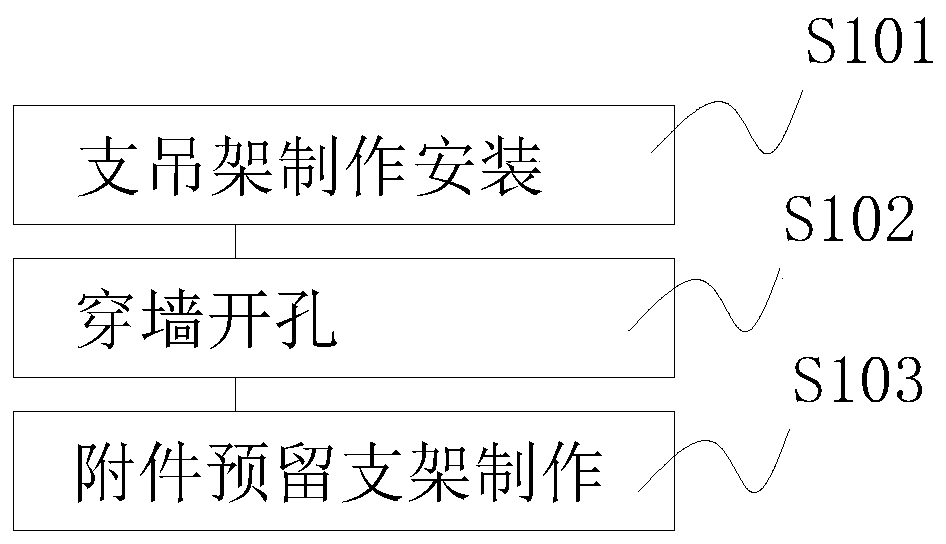

[0059] Wherein, the pipeline layout in the S1 includes the following steps:

[0060] S101. Fabrication and installation of hangers;

[0061] S102, opening holes through the wall;

[0062] S103, manufacture of reserved brackets for accessories;

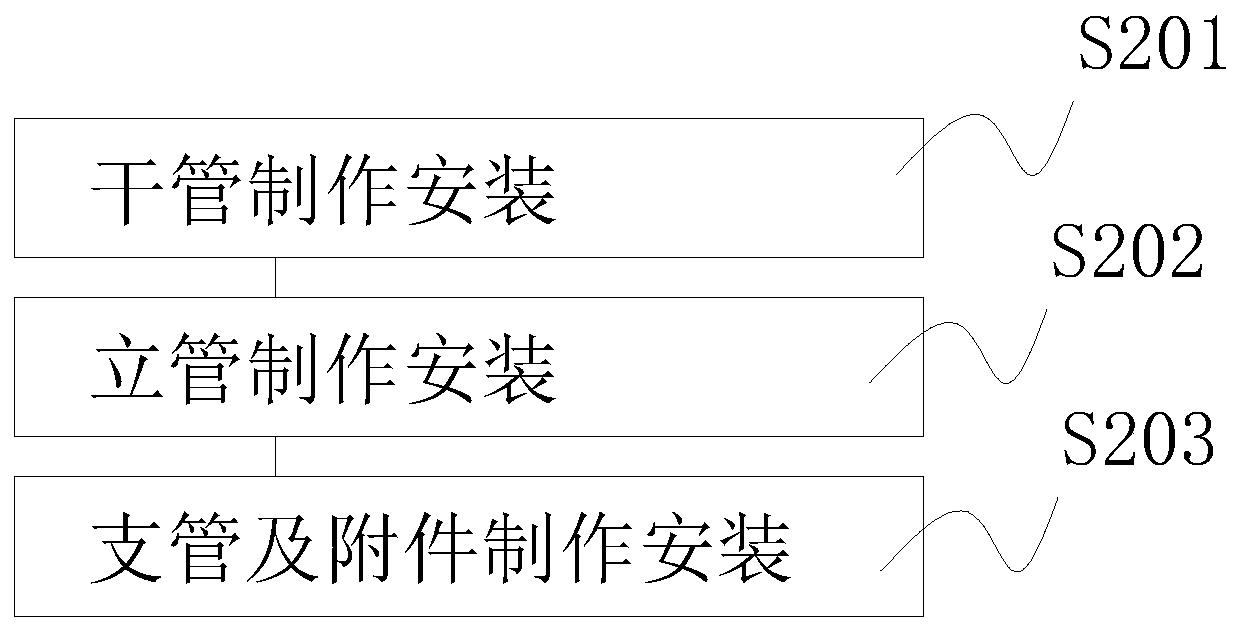

[0063] Wherein, the pipeline prefabrication proces...

Embodiment 2

[0071] Embodiment two: refer to Figure 1-5 , a waterproof and thermal insulation construction method for building water supply and drainage and heating engineering, comprising the following steps:

[0072]S1. Pipe line layout, carry out on-site line layout layout for water supply, drainage and heating engineering pipelines according to the design;

[0073] S2. Pipeline prefabrication processing, pipeline prefabrication processing according to the pipeline line;

[0074] S3, pipeline installation;

[0075] S4. Hydrostatic test;

[0076] S5. Pipeline anti-corrosion and heat preservation;

[0077] S6, rinse and disinfect;

[0078] S7. Treatment of the impact of waterproofing.

[0079] Wherein, the pipeline layout in the S1 includes the following steps:

[0080] S101. Fabrication and installation of hangers;

[0081] S102, opening holes through the wall;

[0082] S103, manufacture of reserved brackets for accessories;

[0083] Wherein, the pipeline prefabrication process...

Embodiment 3

[0096] Embodiment three: refer to Figure 1-6 , a waterproof and thermal insulation construction method for building water supply and drainage and heating engineering, comprising the following steps:

[0097] S1. Pipe line layout, carry out on-site line layout layout for water supply, drainage and heating engineering pipelines according to the design;

[0098] S2. Pipeline prefabrication processing, pipeline prefabrication processing according to the pipeline line;

[0099] S3, pipeline installation;

[0100] S4. Hydrostatic test;

[0101] S5. Pipeline anti-corrosion and heat preservation;

[0102] S6, rinse and disinfect;

[0103] S7. Treatment of the impact of waterproofing.

[0104] Wherein, the pipeline layout in the S1 includes the following steps:

[0105] S101. Fabrication and installation of hangers;

[0106] S102, opening holes through the wall;

[0107] S103, manufacture of reserved brackets for accessories;

[0108] Wherein, the pipeline prefabrication proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com