Graphene polystyrene board and preparation method thereof

A technology of polystyrene board and graphene, applied in the field of polystyrene board, can solve the problems of inhibition effect, agglomeration of polymerization kettle, increase of water absorption rate and thermal conductivity, etc., to increase antibacterial and mildew resistance, and good mechanical strength , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

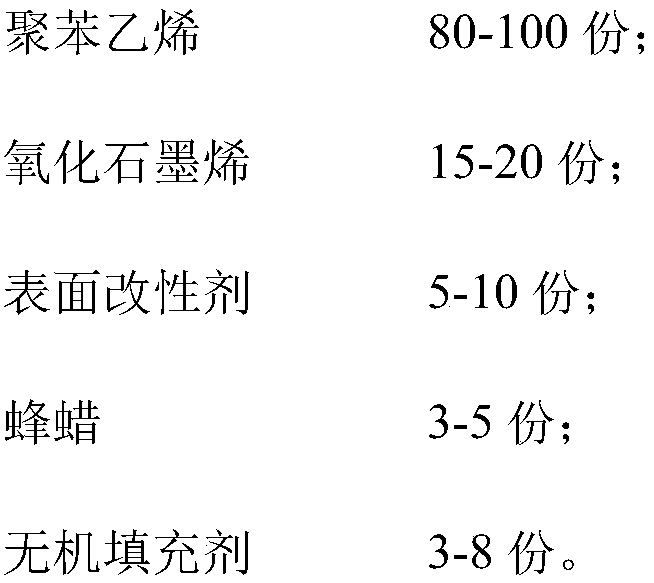

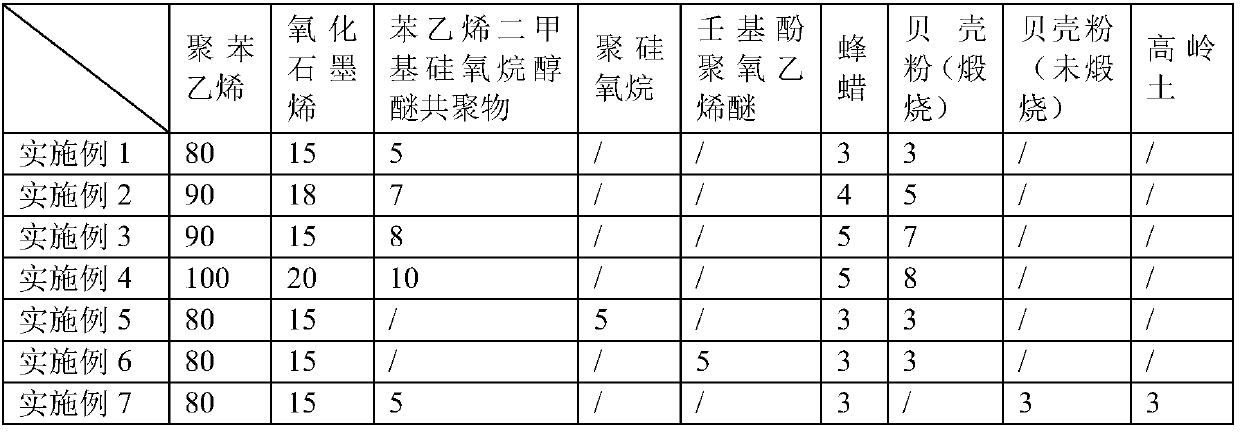

[0042] 1. Preparation examples of raw materials and / or intermediates

[0043] Polystyrene used in the present invention, graphene oxide, styrene dimethyl siloxanol ether copolymer, polysiloxane, nonylphenol polyoxyethylene ether, beeswax, shell powder and kaolin are all from the market purchase proceeds.

[0044] Among them, the shell powder is placed in a high-temperature furnace before use, calcined at a temperature of 1000±5°C for 30 minutes, and cooled to room temperature for later use.

[0045] 2. Embodiment

[0046] 2.1. Embodiment 1

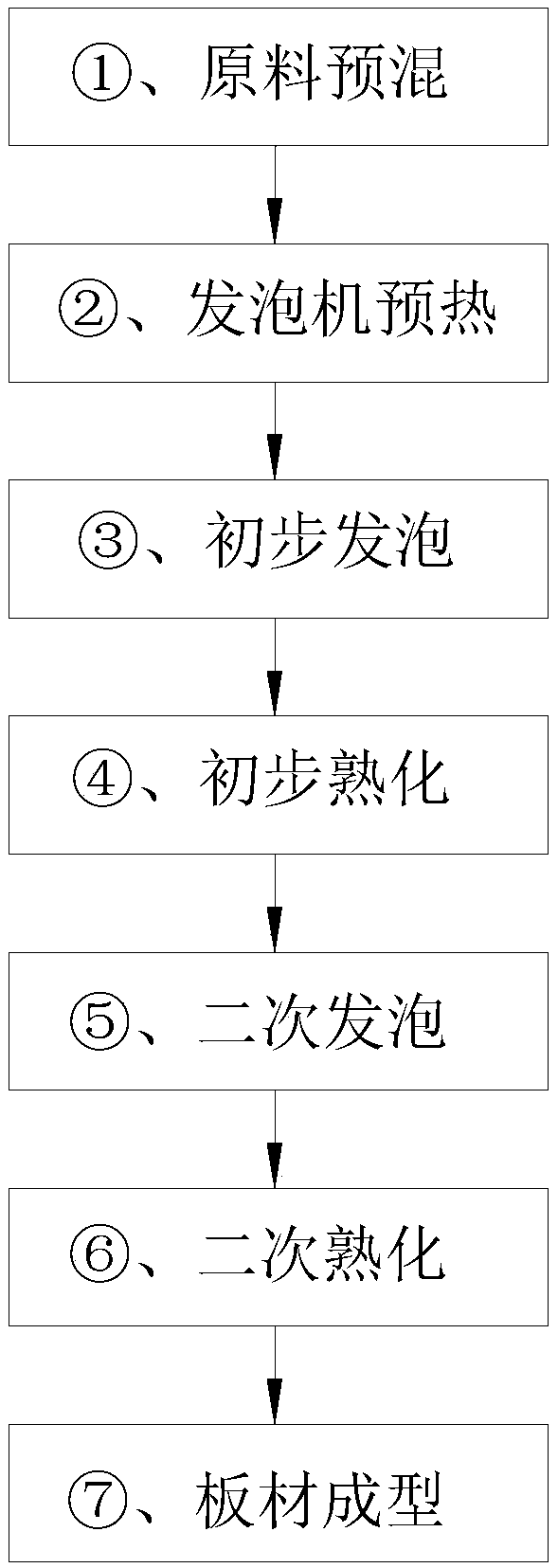

[0047] A kind of preparation method of graphene polystyrene plate, comprises the following specific steps:

[0048] ①. Raw material premixing: Weigh 80kg of polystyrene, 15kg of graphene oxide, 5kg of styrene dimethyl siloxane alcohol ether copolymer, 3kg of beeswax and 3kg of calcined shell powder in sequence, heat and stir Obtain the premix after homogenization;

[0049] ②. Foaming machine preheating: turn on the power, start the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com