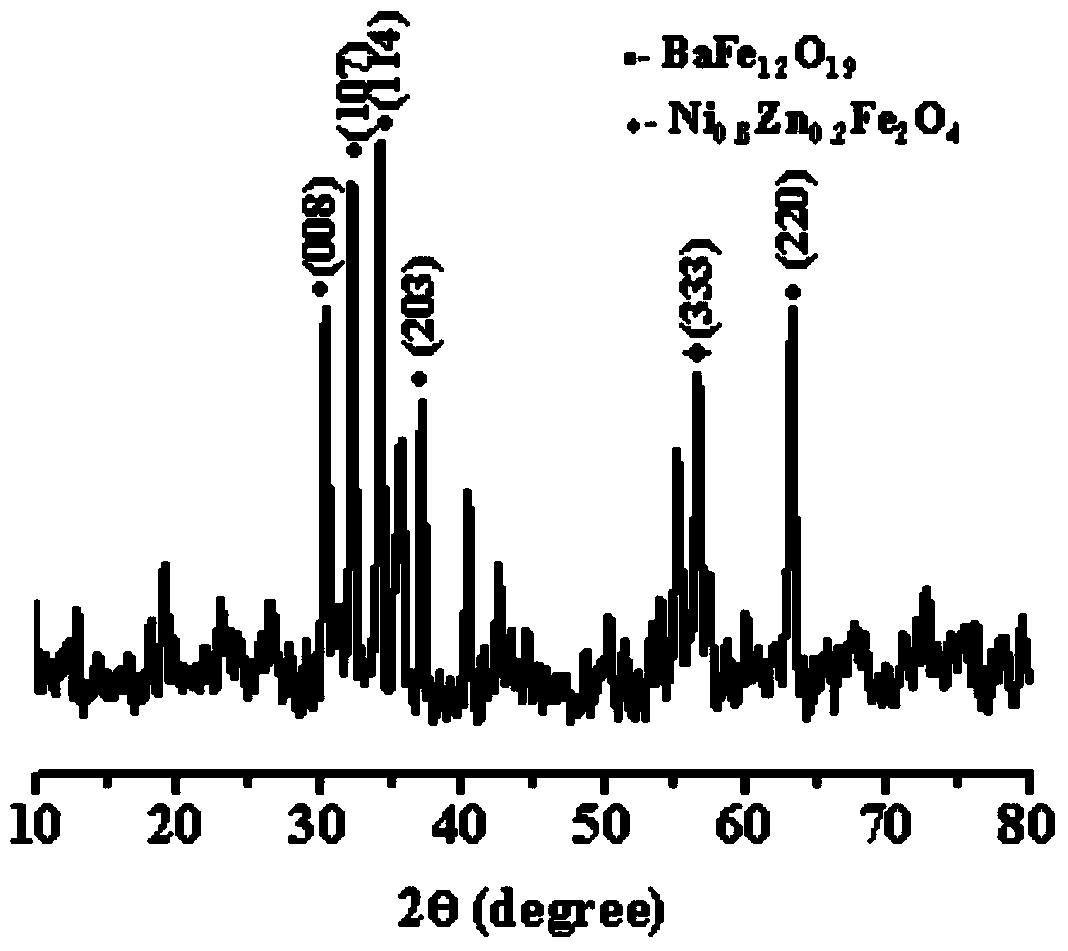

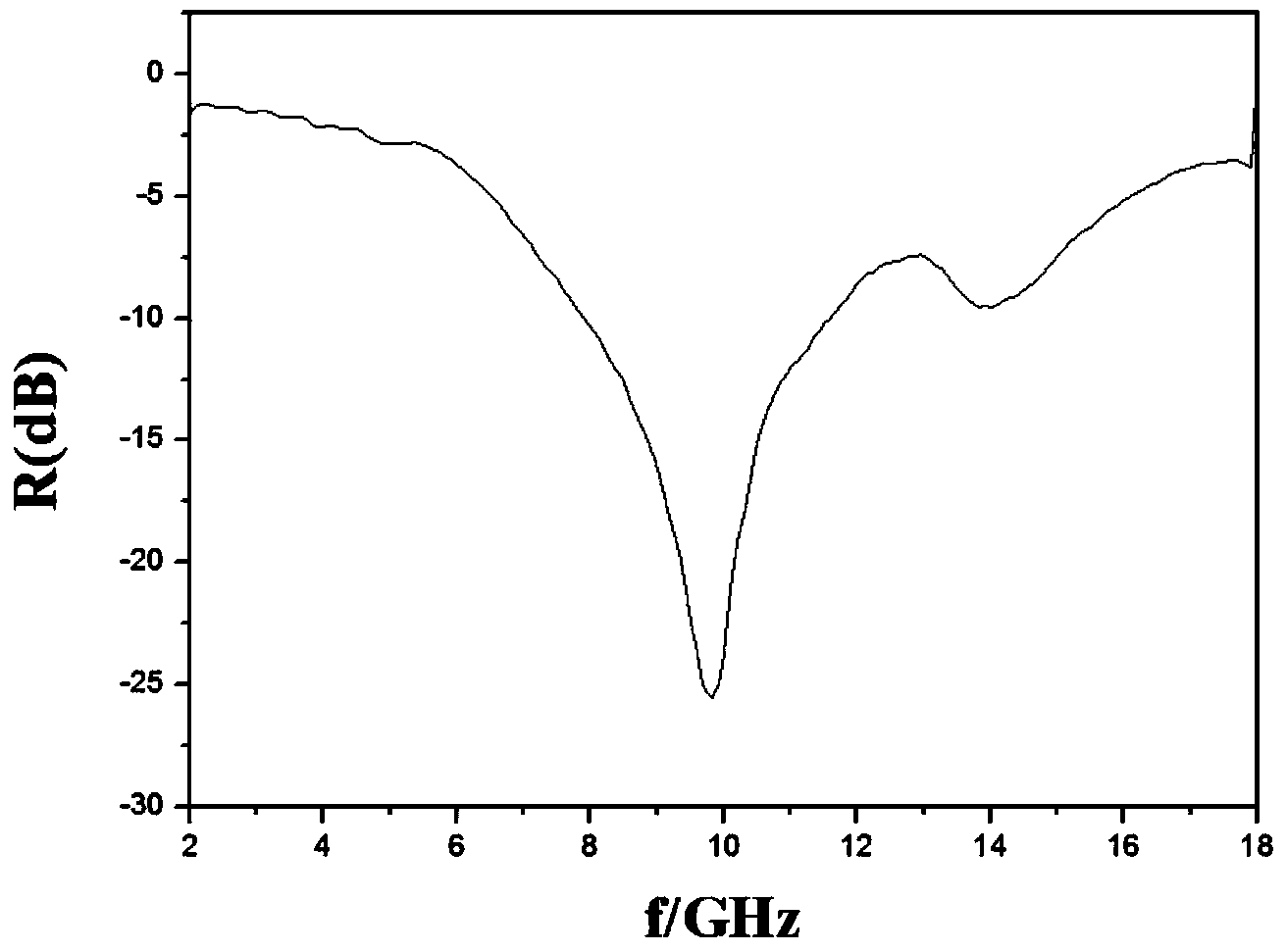

Preparation method of polypyrrole/BaFe12O19-Ni0.8Zn0.2Fe2O4/graphene nano wave-absorbing material

A technology of bafe12o19-ni0.8zn0.2fe2o4, nano-absorbing materials, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of small absorbing loss and poor absorbing performance, and achieve good absorbing performance , Broaden the microwave absorption frequency band, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

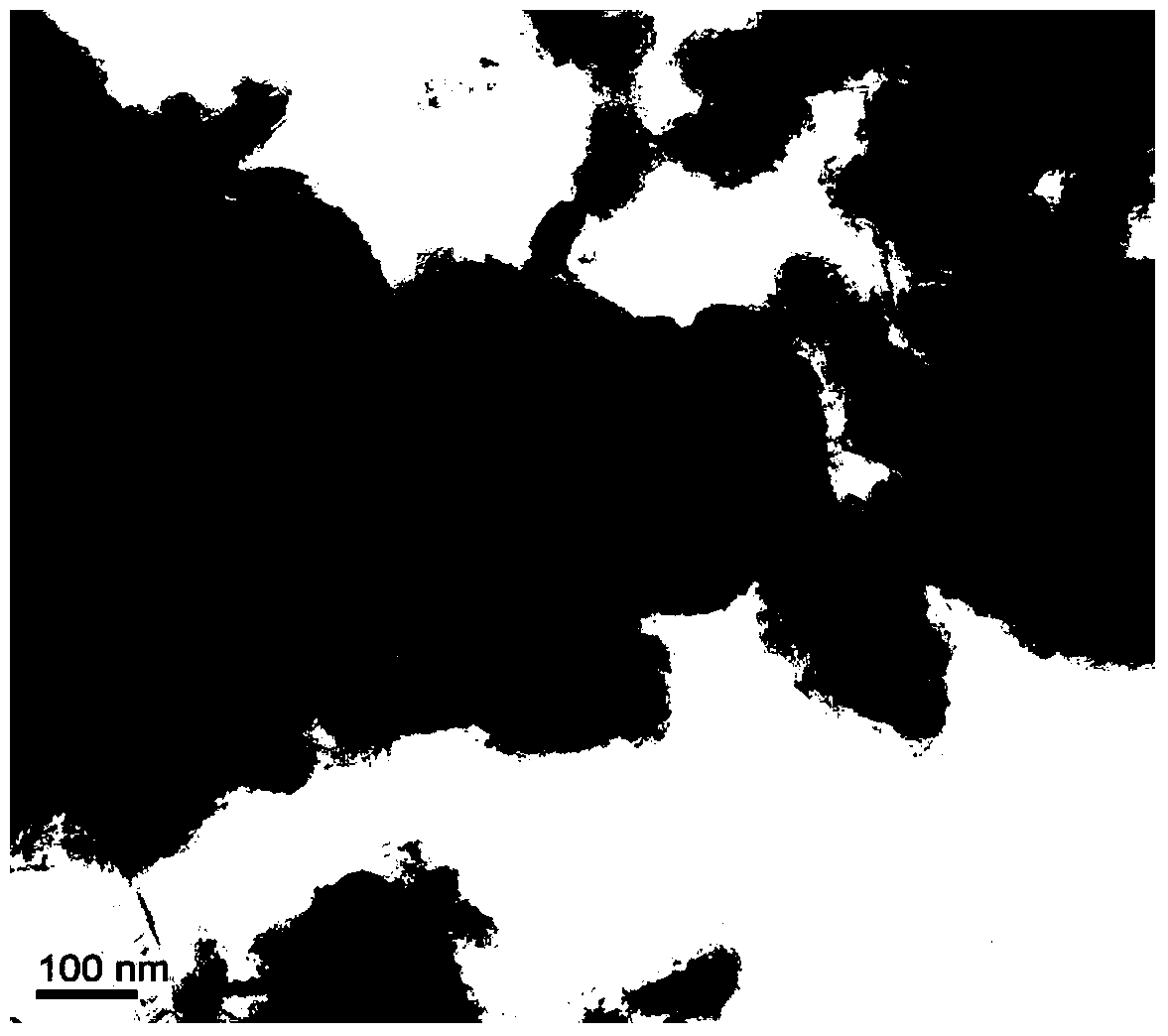

[0021] (1) Polypyrrole / BaFe 12 o 19 -Ni 0.8 Zn 0.2 Fe 2 o 4 Preparation of:

[0022] 1g BaFe 12 o 19 -Ni 0.8 Zn 0.2 Fe 2 o 4 Add the nanoparticles into 200mL of deionized water, stir to make them evenly dispersed, then add 0.5mL of pyrrole monomer to the system, stir for a while, add 4.55g of FeCl 3 ·6H 2 O (2.33:1 molar ratio to pyrrole monomer) was dissolved in 100 mL of deionized water, and slowly added dropwise to the above mixed solution with a dropping funnel, and the polymerization reaction was stirred at 0°C for 12 hours. After the reaction, the resulting black solution was washed with absolute ethanol and deionized water until the filtrate was colorless, and dried in vacuum at 60°C for 24 hours to obtain PPy / BaFe 12 o 19 -Ni 0.8 Zn 0.2 Fe 2 o 4 nanocomposites.

[0023] (2) Synthesis of polypyrrole / BaFe by mechanical reduction method 12 o 19 -Ni 0.8 Zn 0.2 Fe 2 o 4 / graphene composites

[0024] 0.08g graphite oxide and 1.5g PPy / BaFe 12 o 19 ...

Embodiment 2

[0027] (1) Polypyrrole / BaFe 12 o 19 -Ni 0.8 Zn 0.2 Fe 2 o 4 Preparation of:

[0028] 1g BaFe 12 o 19 -Ni 0.8 Zn 0.2 Fe 2 o 4 Add the nanoparticles into 200mL of deionized water, stir to make them evenly dispersed, then add 0.5mL of pyrrole monomer to the system, stir for a while, add 4.55g of FeCl 3 ·6H 2 O (2.33:1 molar ratio to pyrrole monomer) was dissolved in 100 mL of deionized water, and slowly added dropwise to the above mixed solution with a dropping funnel, and the polymerization reaction was stirred at 0°C for 12 hours. After the reaction, the resulting black solution was washed with absolute ethanol and deionized water until the filtrate was colorless, and dried in vacuum at 60°C for 24 hours to obtain PPy / BaFe 12 o 19 -Ni 0.8 Zn 0.2 Fe 2 o 4 nanocomposites.

[0029] (2) Synthesis of polypyrrole / BaFe by mechanical reduction method 12 o 19 -Ni 0.8 Zn 0.2 Fe 2 o 4 / graphene composites

[0030] 0.2g graphite oxide and 1.5g PPy / BaFe 12 o 19 -...

Embodiment 3

[0033] (1) Polypyrrole / BaFe 12 o 19 -Ni 0.8 Zn 0.2 Fe 2 o 4 Preparation of:

[0034] 1g BaFe 12 o 19 -Ni 0.8 Zn 0.2 Fe 2 o 4 Add the nanoparticles into 200mL of deionized water, stir to make them evenly dispersed, then add 0.5mL of pyrrole monomer to the system, stir for a while, add 4.55g of FeCl 3 ·6H 2 O (2.33:1 molar ratio to pyrrole monomer) was dissolved in 100 mL of deionized water, and slowly added dropwise to the above mixed solution with a dropping funnel, and the polymerization reaction was stirred at 0°C for 12 hours. After the reaction, the resulting black solution was washed with absolute ethanol and deionized water until the filtrate was colorless, and dried in vacuum at 60°C for 24 hours to obtain PPy / BaFe 12 o 19 -Ni 0.8 Zn 0.2 Fe 2 o 4 nanocomposites.

[0035] (2) Synthesis of polypyrrole / BaFe by mechanical reduction method 12 o 19 -Ni 0.8 Zn 0.2 Fe 2 o 4 / graphene composites

[0036] 0.27g graphite oxide and 1.5g PPy / BaFe 12 o 19 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Return loss | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com