Plating liquid separating-recovering system and control method of brush plating machine

A technology of separation and recovery and recovery system, applied in the direction of cells, electrolytic components, electrolytic process, etc., can solve the problems of high production cost and limit the development of brush plating machines, and achieve the effect of low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with accompanying drawing:

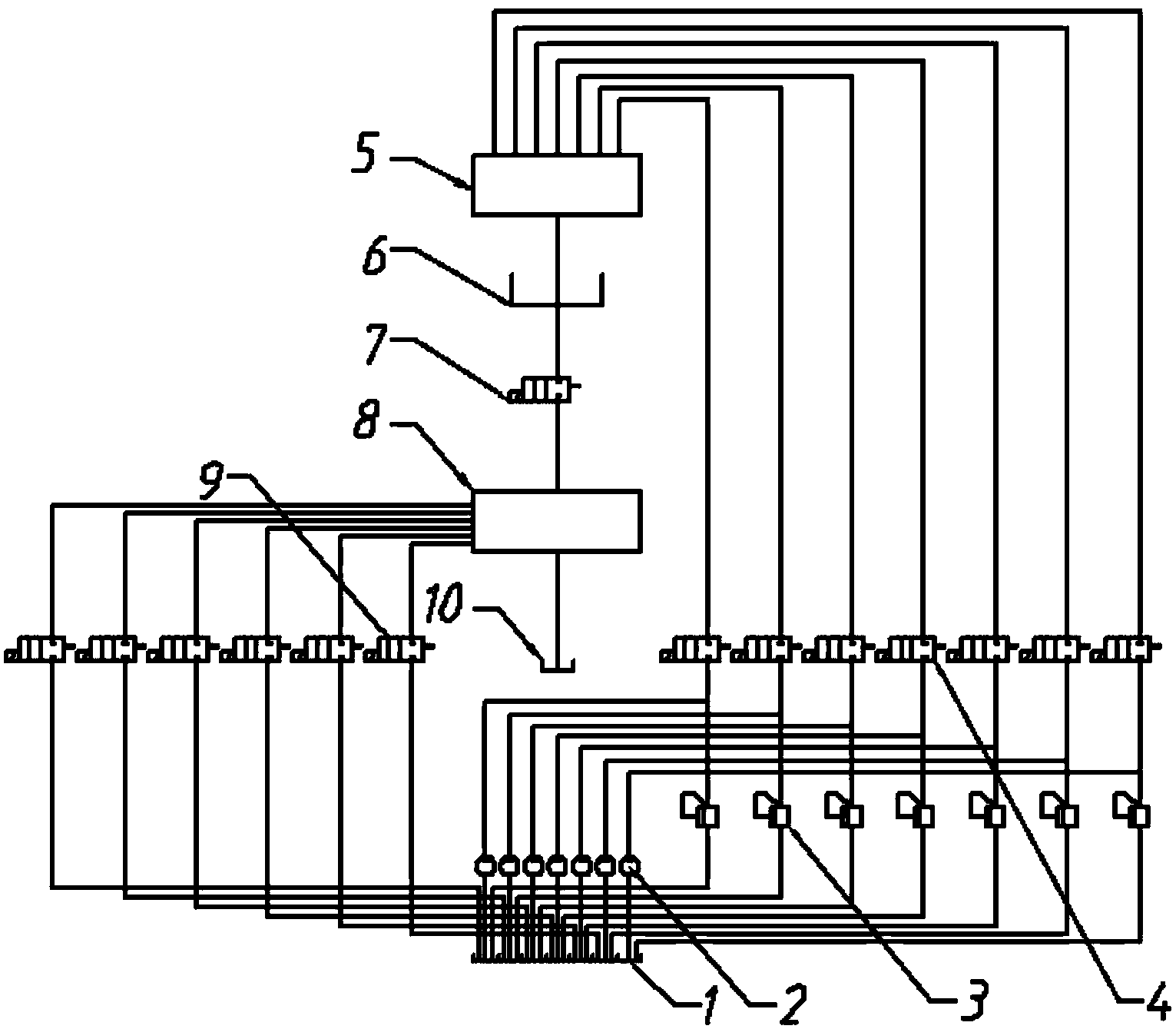

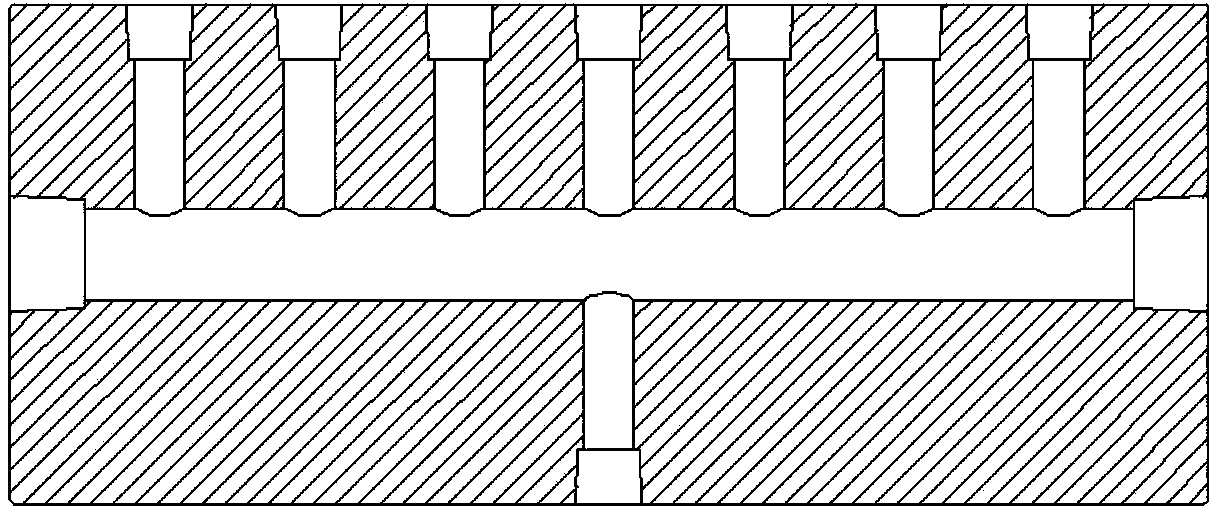

[0034] The device belongs to a part of the hydraulic circuit of the plating solution of the brush plating machine. The brush plating machine is mainly used for brush plating inner holes such as connecting rods and engine cylinder blocks. A hydraulic circuit is designed, which consists of liquid storage tank 1, hydraulic pump I2, overflow valve 3, solenoid valve I4, liquid separator 5, connecting rod inner hole 6, solenoid valve II7, plating solution separation and recovery device 8, solenoid valve III9 , Waste liquid tank 10 forms. Wherein, the plating solution separation and recovery device is installed between the solenoid valve III9 and the solenoid valve II7. The schematic diagram of the hydraulic part is as follows: figure 1 shown. The liquid storage tank 1 is divided into a plurality of independent liquid storage rooms, and the outlet of each liquid storage room is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com