Disc-type engine oil cooling and filter combined device of diesel engine

An oil cooler and oil filter technology, which is applied in the installation/connection of machines/engines, lubricant purification devices, mechanical equipment, etc. Oil leakage and other problems on the surface, to achieve the effect of improving assembly quality, small volume, and reducing the possibility of oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The following describes the technical solution of the present invention in detail through a best embodiment in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiment.

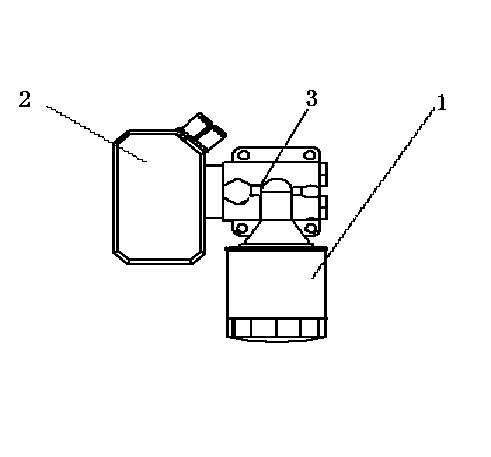

[0010] Such as figure 1 As shown, the oil cooler and filter used on the traditional R4105 diesel engine are arranged in a dog-shaped shape, and the filter seat 3 is connected to the left oil cooler 2 and the lower oil filter 1 respectively. The vertically downward arrangement of the oil filter 1 not only takes up more space, but also increases the area of the joint surface.

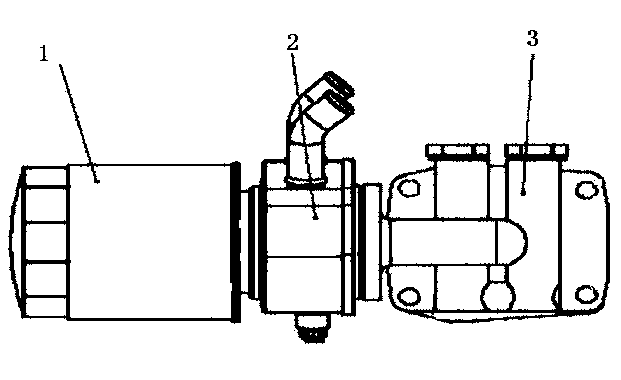

[0011] The improved disc-type oil cooling and filter combination device such as figure 2 As shown, the oil filter 1, the oil cooler 2 and the filter seat 3 are placed horizontally, and the oil cooler 2 adopts a disc-shaped oil cooler with better heat dissipation performance. At the same time, the filter seat 3 The oil passage inside is refitted so that it c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com