Power output machine

A technology of power output and rotating rods, which is applied in the direction of engines, machines/engines, mechanical equipment, etc., to achieve the effect of small friction and reduced capacity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

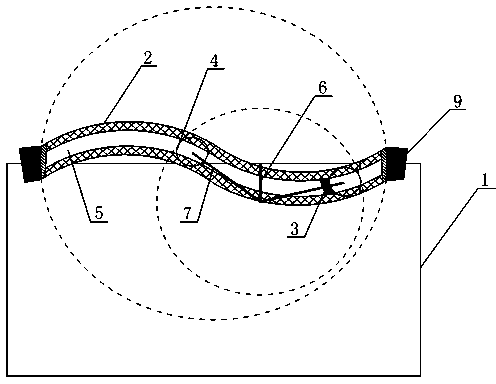

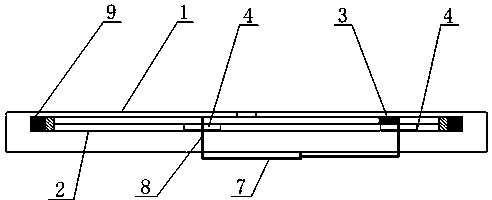

[0026] Such as Figure 1-6 As shown, a power take-off machine includes a support 1, a slideway 2 arranged on the support 1 and movably connected with it, and a slider 3 and a main bearing 4 arranged in the slideway 2; the support 1 is also provided with There is a control piece for controlling the motion track of the main bearing 4. The specific setting is that the slideway is connected with the support through the rotating shaft, and the control part is also connected with the support through the rotating shaft, and the control part and the slideway are not on the same plane, so figure 2 can be seen in.

[0027] The above-mentioned slideway 2 is a double-layer inner hollow structure, the slider 3 is located at the bottom layer, and the main bearing 4 is located at the top layer; the slideway 2 is also provided with a groove 5 that can communicate with the top layer and the bottom layer, and the control member wears Extend to the bottom layer through the groove 5; at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com