Solenoid pressure relief valve

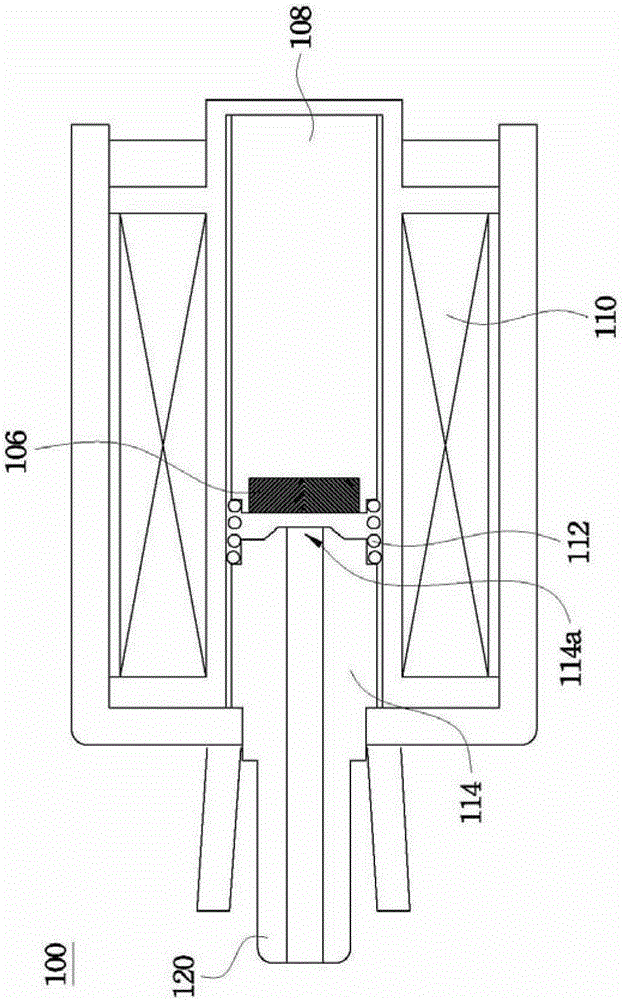

A pressure relief valve and electromagnetic technology, applied in the field of solenoid valves, can solve the problems of increased overall cost of the electromagnetic pressure relief valve 100 and the inability to reduce manufacturing costs, and achieve the effects of reduced manufacturing hours, reduced manufacturing costs, and improved pressure relief efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

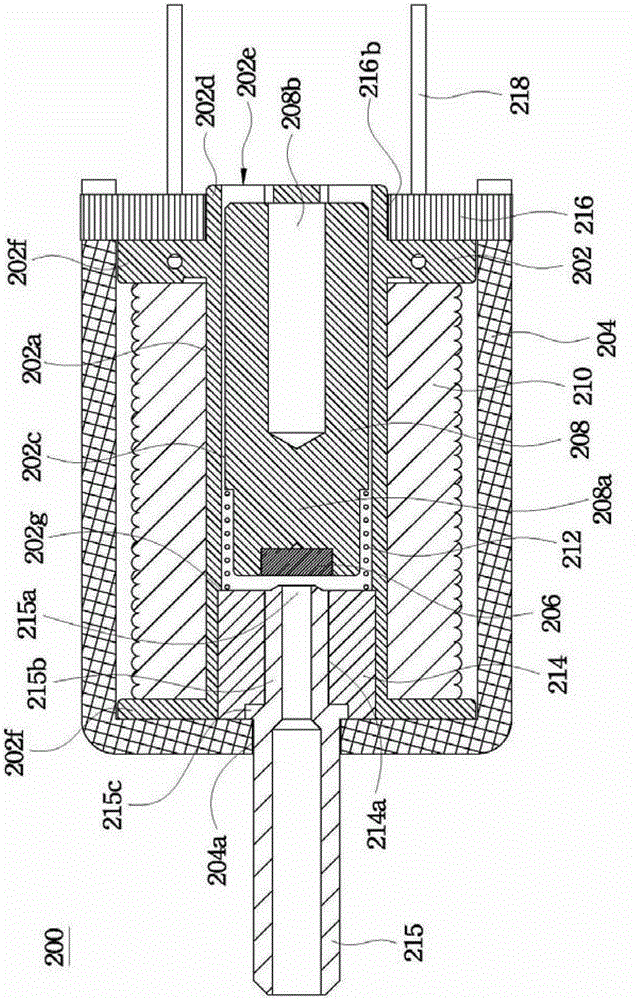

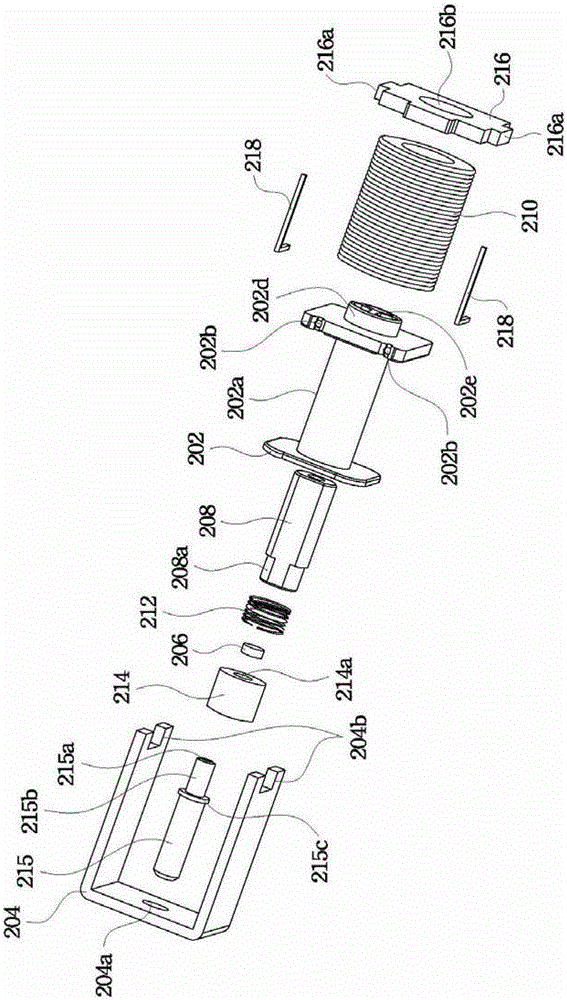

[0031] Please also refer to figure 2 , 3 , figure 2 is a sectional view illustrating an electromagnetic pressure relief valve according to an embodiment of the present invention, image 3 is to draw figure 2 Exploded view of the solenoid pressure relief valve. The electromagnetic pressure relief valve 200 basically consists of an outer frame 204 , a magnet collector 214 , a plastic valve 215 , a coil module, a movable inner core 208 and a spring 212 . The plastic valve 215 is used to connect to a pipeline that needs to be released for pressure relief, and the pipeline that needs to be released can be any fluid pipeline. Under normal conditions, the electromagnetic pressure relief valve 200 utilizes the elastic force of the spring 212 to prevent the air inlet 215a from being blocked or sealed by the anti-leakage gasket 206, and flows through the hollow groove 202c to the pressure relief hole 202e to release the pressure, so that the pipe that needs pressure relief The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com