Calibrating and aligning method of CCD (Charge-coupled Device) camera

A camera and alignment platform technology, applied in photogrammetry/video surveying, measuring devices, instruments, etc., can solve the problems of unavoidable mechanical motion errors, affecting calibration and alignment accuracy, and difficult to meet process requirements, etc. Achieving the effect of simplified steps, improved accuracy, and reduced time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific embodiments.

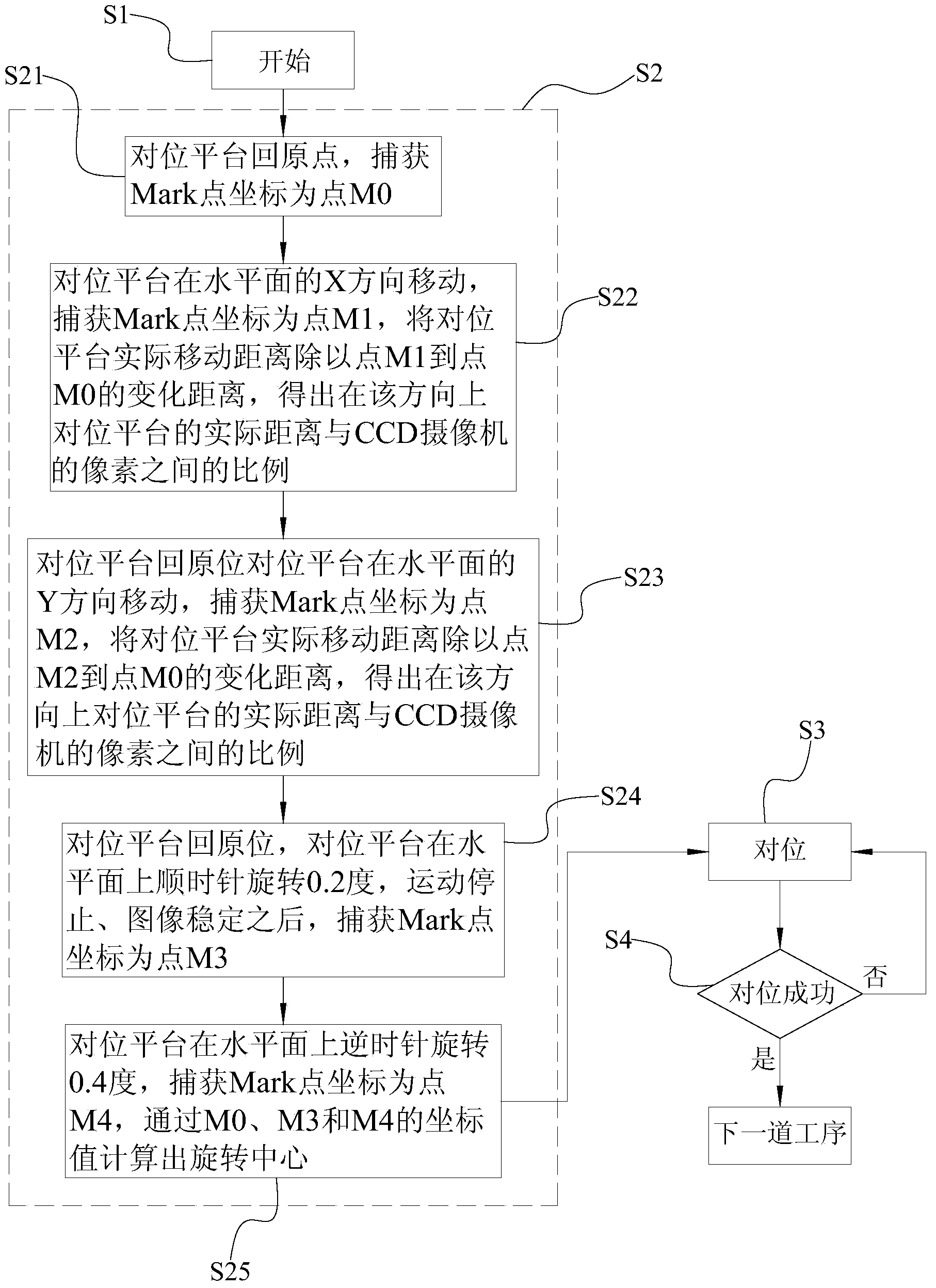

[0025] The schematic flow chart of the embodiment of the present invention is as figure 1 shown. CCD camera calibration alignment method of the present invention has included the following steps:

[0026] Step S1, the standard sample is fixed on the alignment platform with Mark points on the standard sample, and there are two CCD cameras above the alignment platform, and the control unit controls the alignment platform and the two CCD cameras to start working;

[0027] Step S2, calibration of two CCD cameras: the alignment platform is quantitatively offset and rotated on the horizontal plane, and after the movement of the alignment platform stops, the two CCD cameras record the Mark point of the standard sample after each movement of the alignment platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com