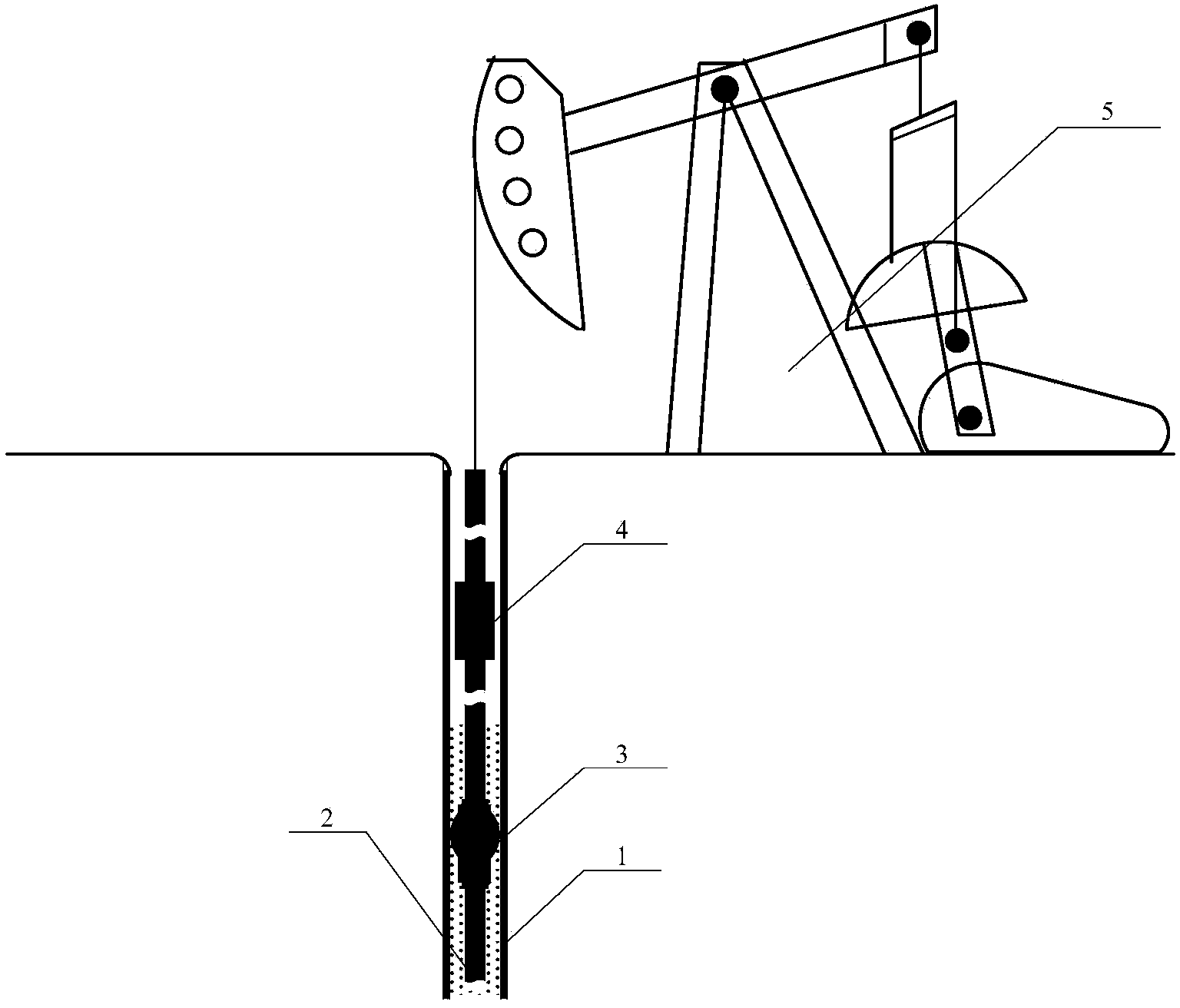

Sucker rod mechanical parameter measurement device

A technology for measuring devices and sucker rods, applied in measuring devices, force/torque/work measuring instruments, measuring force components, etc., can solve problems such as tube eccentric wear and rod eccentric wear, and achieve regular structure, simple structure, Excellent technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those of ordinary skill in the art to clearly understand the technical scheme of the present invention, the specific embodiments of the present invention will be further described in conjunction with the accompanying drawings:

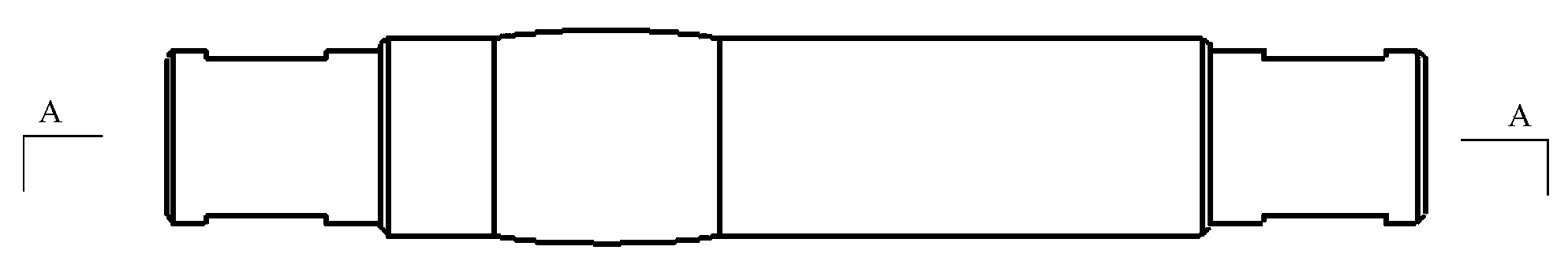

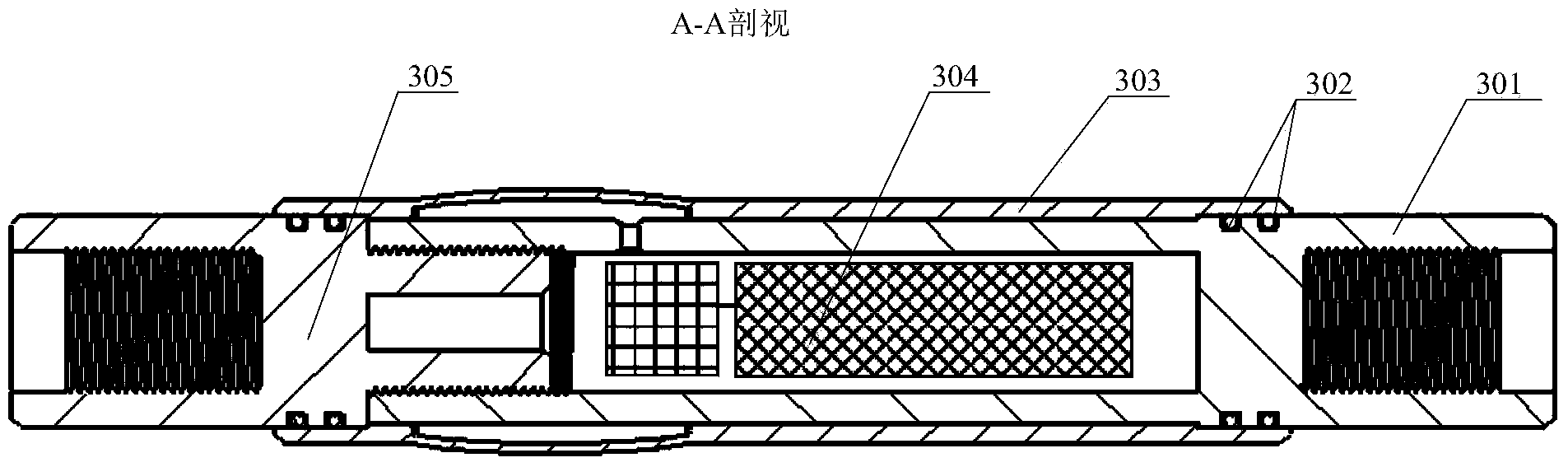

[0034] The present invention forms a special structure with the stress concentration filter 303, the long joint cabin 301 and the short joint 305, and forms a special part on the measuring short joint 3, so that the protruding part of the stress concentration filter 303 only bears radial force, while the long joint cabin The strain gauge sticking area 30103 of 301 only bears axial force and torque. In these parts, the high temperature resistant strain gauge 30108 sensors are used to build bridge-type measurement circuits 30409 and 30410 respectively, and the microelectric measurement control system 304 is used to solve the problem of downhole sucker rod Measuring problems of mechanical properties. In addition to measuring mech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com