Device for detecting washing fastness of stockings

A technology of washing fastness and testing devices, which is applied in the field of machinery, can solve the problems of expensive washing fastness testing instruments, lax product quality control, and enterprises ignoring socks control, etc., to achieve simple structure, low production cost, and standardize the market Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

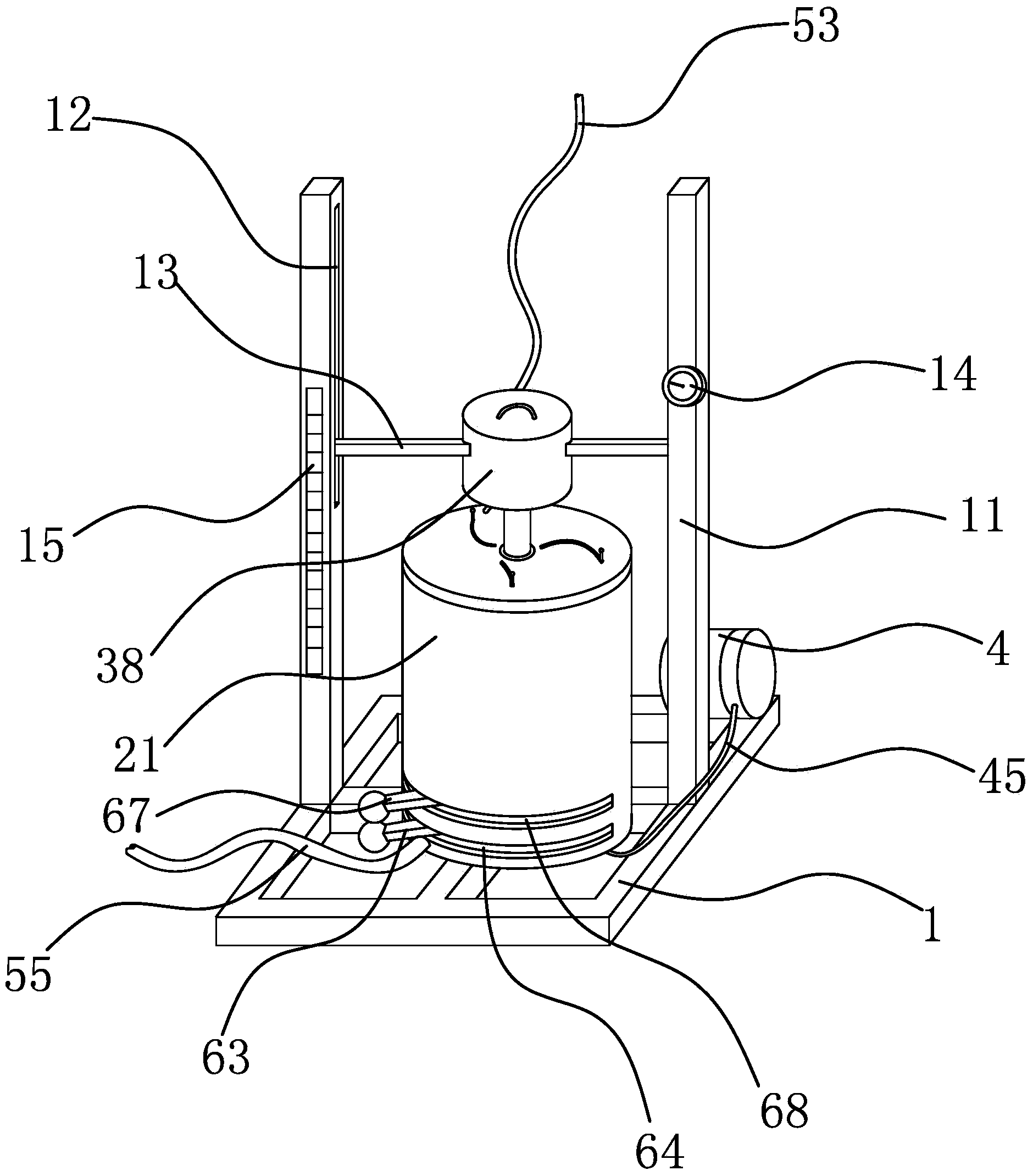

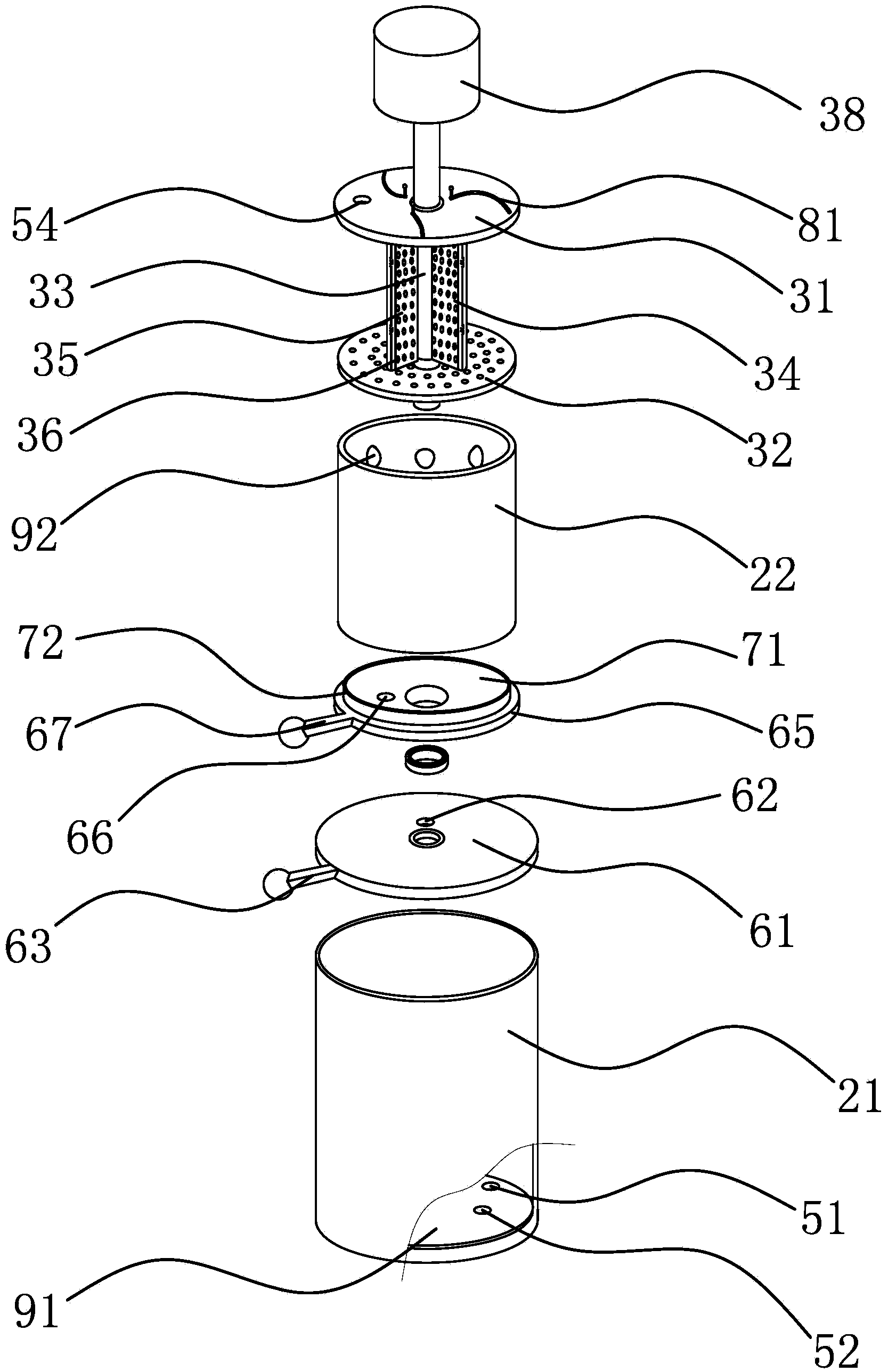

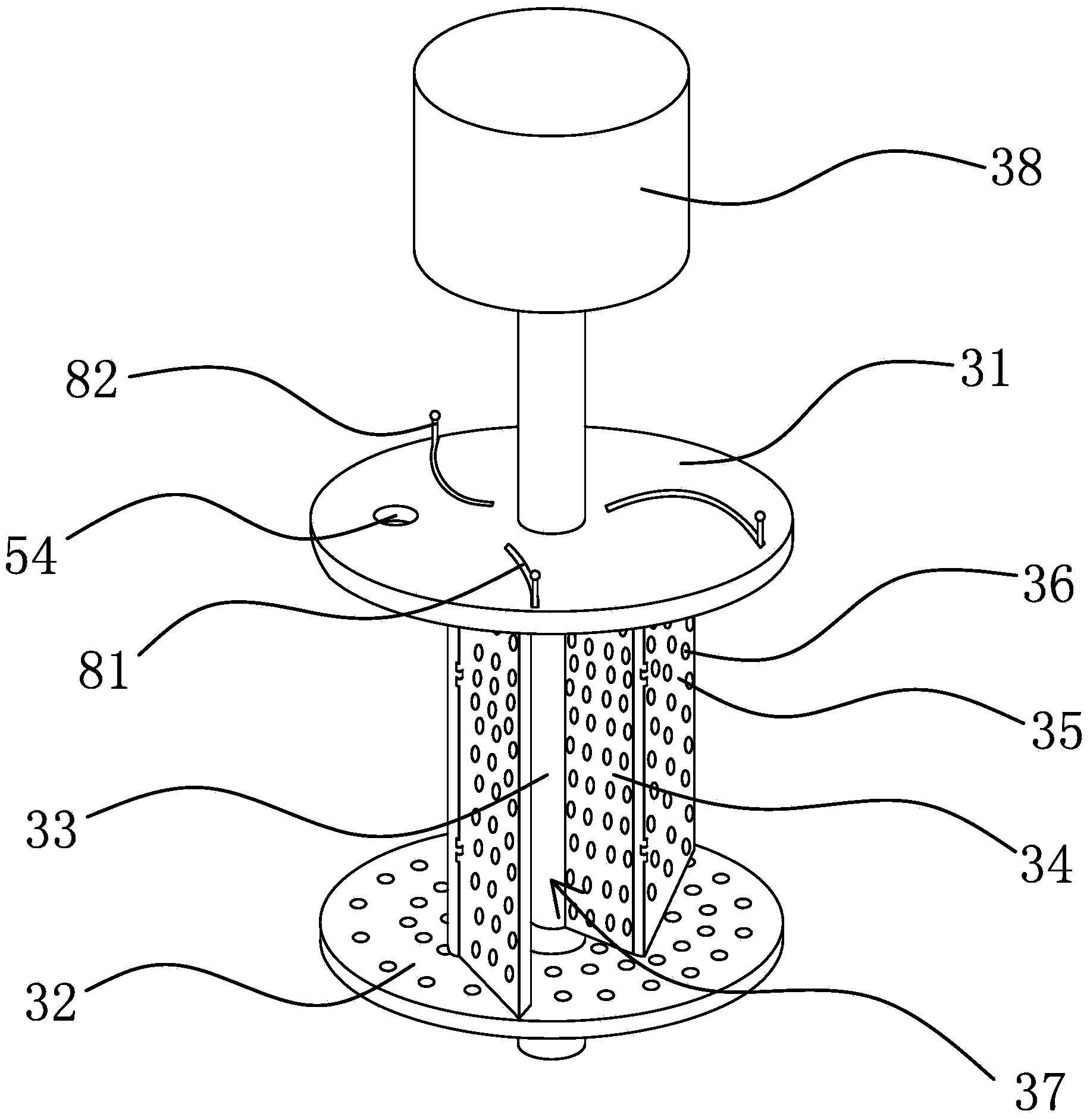

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0028] Such as figure 1 , figure 2 with Figure 4As shown, the washing fastness detection device of the socks comprises a support 1, an outer cylinder 21 is fixedly arranged on the support 1, an inner cylinder 22 is arranged in the outer cylinder 21, and a motor 38 is also provided on the support 1, and the motor 38 is arranged on the support 1. 38 is fixedly provided with a stirring shaft 33 on the output shaft, the upper end of the stirring shaft 33 is provided with a cover plate 31, the lower end of the stirring shaft 33 is provided with a filter plate 32, and several pieces of solid plates are arranged between the cover plate 31 and the filter plate 32. The stirring blade 34 arranged on the stirring shaft 33, the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com