Pole group shaping feeding machine for storage battery cast welding

A battery and pole group technology, which is applied in the field of battery casting and welding pole group shaping and lowering machine, can solve the problems such as the side tabs cannot be folded to the required slope, the labor intensity of manual folding is high, and the quality of lead-acid batteries is affected. , to achieve the effects of reducing environmental pollution and harm to the human body, reducing instability, saving time and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

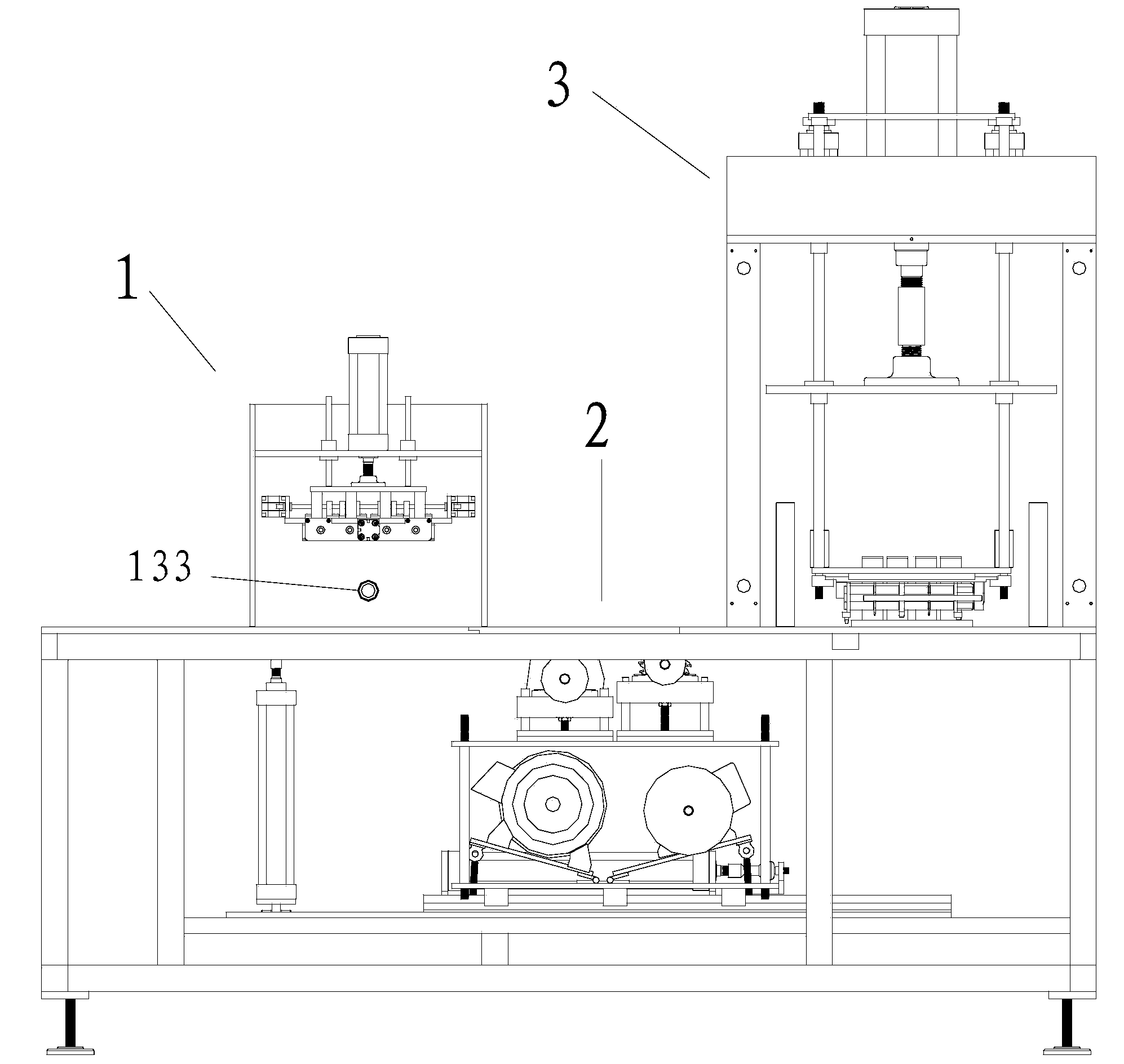

[0046] Such as figure 1 Shown is a schematic diagram of an embodiment of a pole group shaping and slotting machine for battery casting and welding provided by the present invention, which includes a frame and a pole group tab shaping device 1 and an pole group tab cutting and brushing device sequentially arranged on the frame 2 and pole group lower groove device 3.

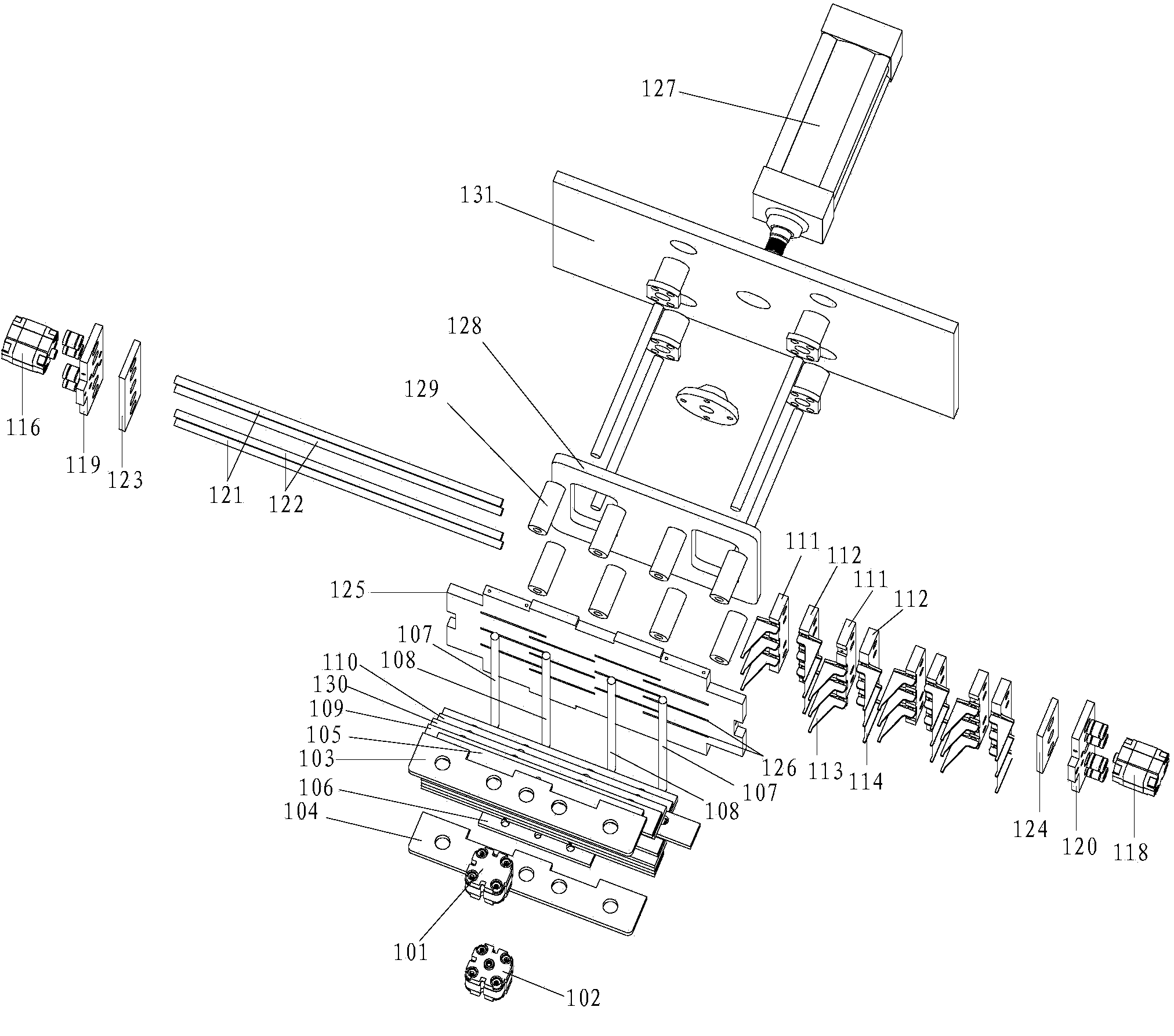

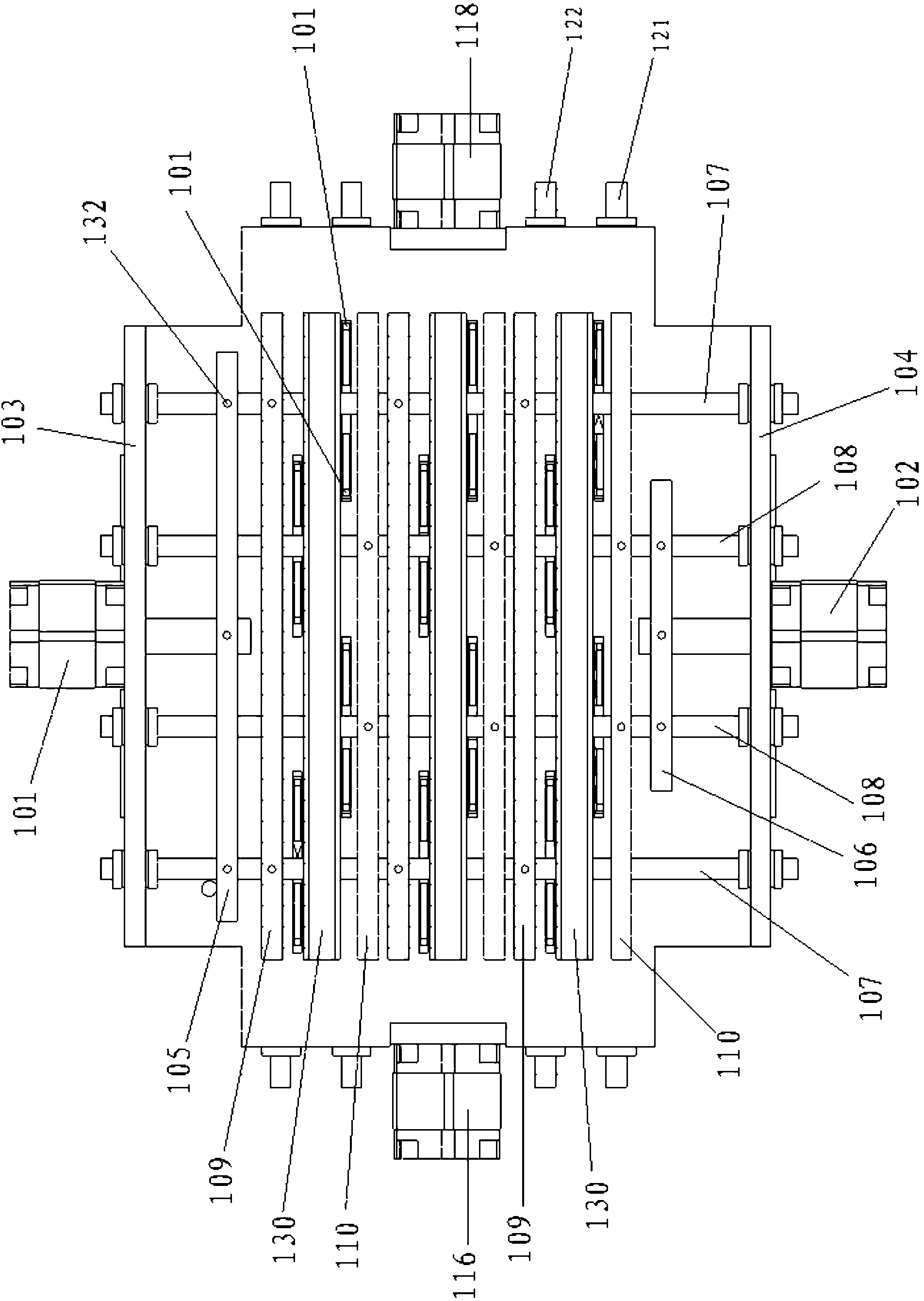

[0047] Such as figure 2 and image 3 Shown is a schematic diagram of an embodiment of a pole group lug shaping device 1 provided by the present invention, which includes a lug leveling drive assembly and several sets of tab leveling components arranged in parallel; the tab drive assembly includes a first shaping drive and the second shaping driver; the lug leveling assembly includes a first shaping plate 109, a second shaping plate 110, and a shaping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com