High-temperature hard solder quasi-continuous semiconductor laser bar stack encapsulating method

A packaging method and hard solder technology, applied in the laser field, can solve the problems of easy cracking of bars and laser failure, etc., and achieve the effect of short cycle time and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

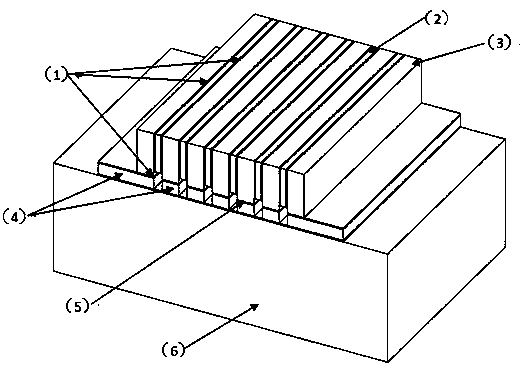

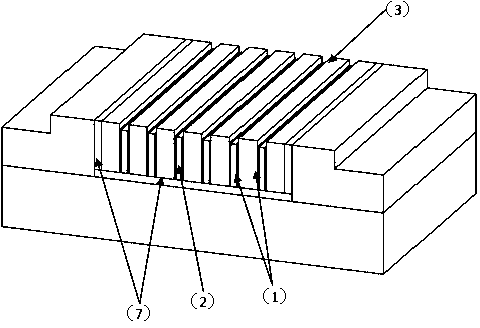

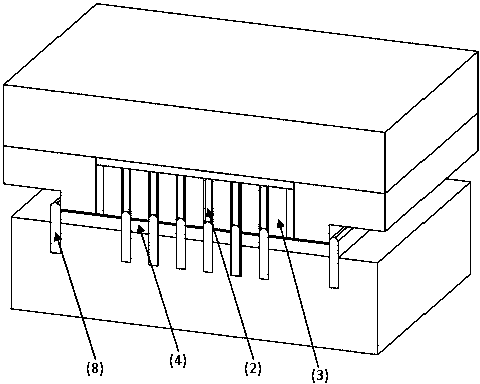

[0034] refer to figure 1 , figure 2 , image 3 , Figure 4 Shown, a kind of high-temperature hard solder quasi-continuous semiconductor laser bar stack packaging method comprises the following steps:

[0035] Step 1) Place an ultra-flat alumina 7 on the bottom surface of the first fixture, first place an ultra-flat alumina 7 on the bottom surface of the first fixture, and then place another ultra-flat alumina 7 from one end, several conductive Heat dissipation spacers 3, the conductive heat dissipation spacers are spaced equally apart by laser bars 2 and high-temperature hard solder 1, and spring pins or screws are placed at the other end of the first tooling fixture to fasten the laser bars. 2. The high-temperature hard solder 1 and the conductive and heat-dissipating spacer 3 are fixed; or the two welding surfaces of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com