Rhizomes material cleaning machine

A rhizome and washing machine technology, which is applied in the field of fruit cleaning and material cleaning, can solve the problems of difficult to accurately control the cleaning time of materials, damage to the surface of materials, and cleaning of hard-to-adhesive soil, so as to avoid damage to the surface of materials and reduce The skin breaking rate and the effect of reducing the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

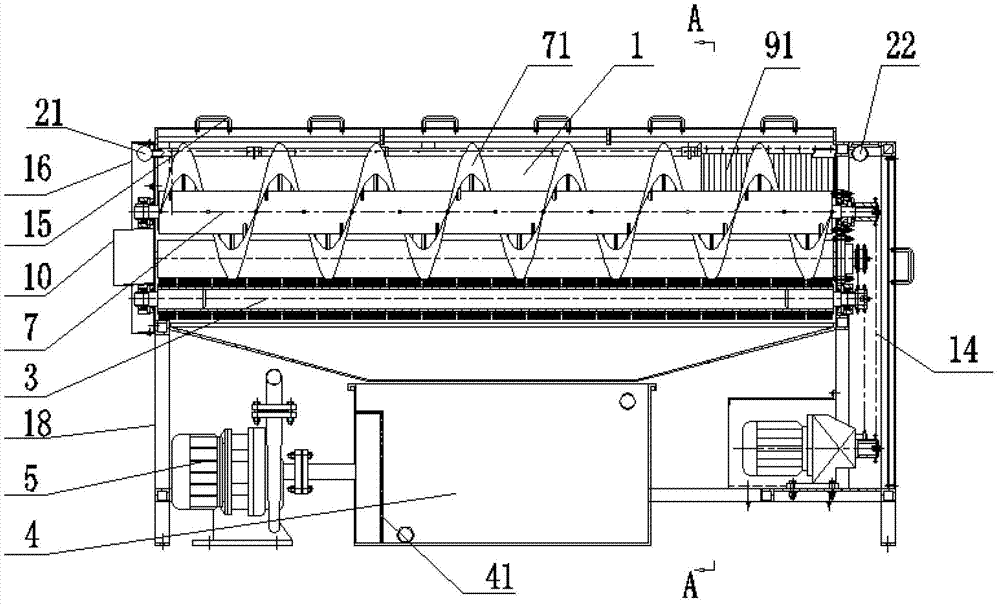

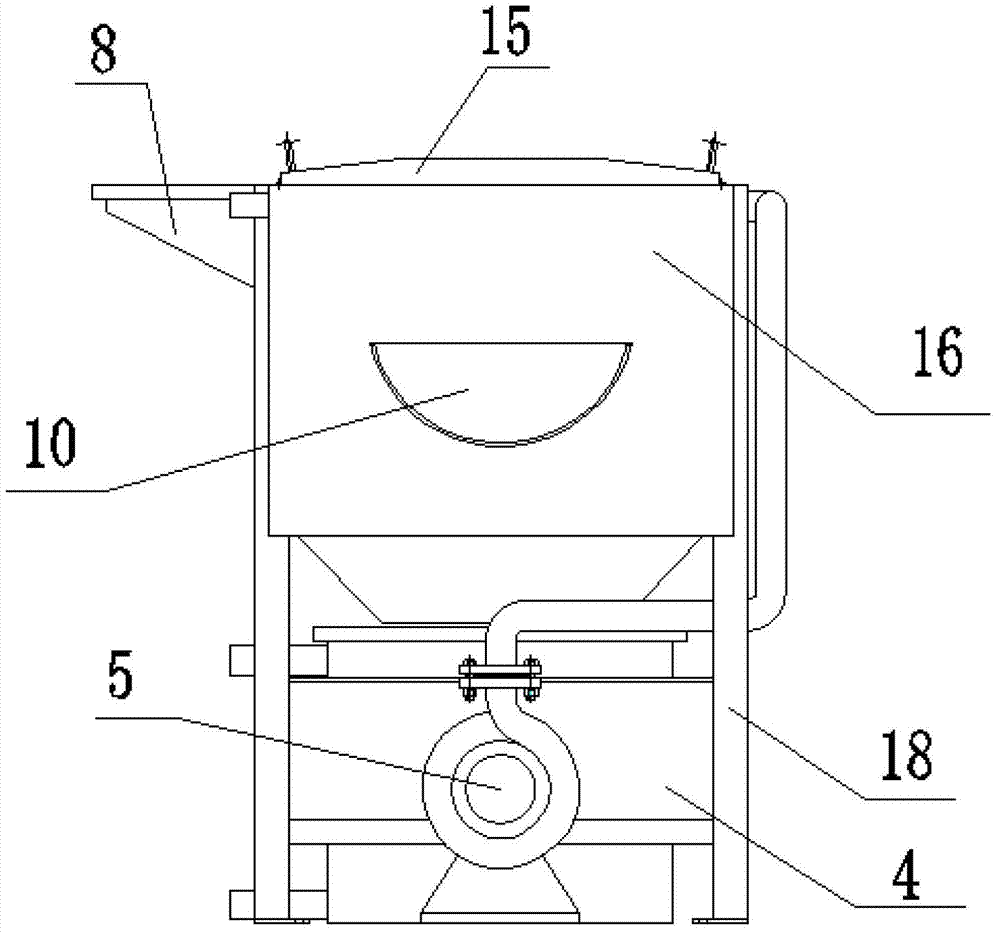

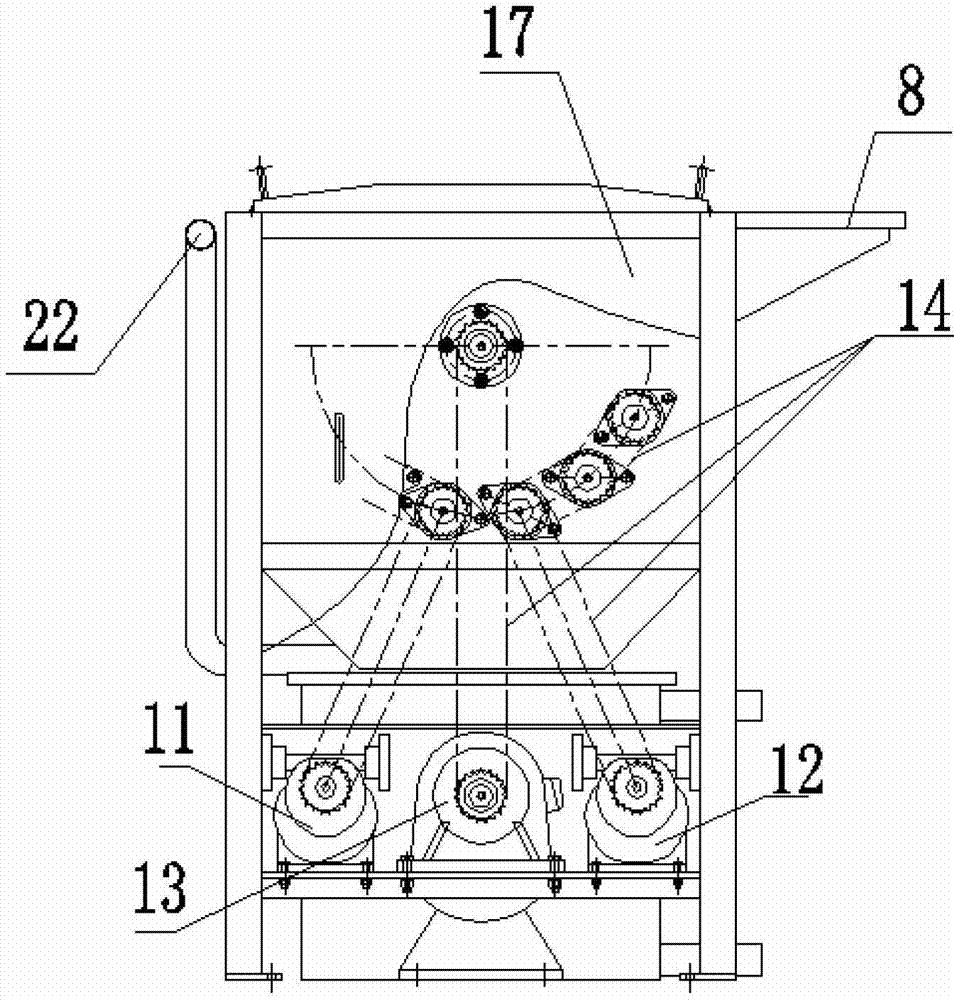

[0038] The invention provides a cleaning machine for rhizome materials, such as figure 1 As shown in the structure, it includes: a frame 18, a cleaning chamber 1, a spray device 2, a cover door 15 located on the upper side of the cleaning chamber 1, a front sealing door 17 at both ends of the cleaning chamber 1, a rear sealing door 16 and a plurality of brushes arranged in parallel Roller 3, wherein the brush roller 3 is arranged in the cleaning chamber 1, the spray device 2 is arranged in the cleaning chamber 1, and is used to spray spray water to the materials in the cleaning chamber 1, and the cleaning chamber 1 is also equipped with a The screw propeller 7 that moves toward the discharge direction, the screw propeller 7 is made up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com