Remote state monitoring system of fire hydrant

A remote monitoring system and fire hydrant technology, applied in fire rescue and other fields, can solve problems such as poor supervision, frequent occurrence of fire safety hazards, delay in rescue time, etc., and achieve the effects of helping maintenance and management, promoting healthy development, and saving rescue time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

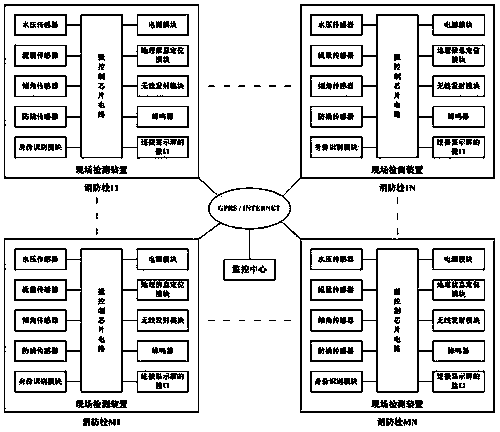

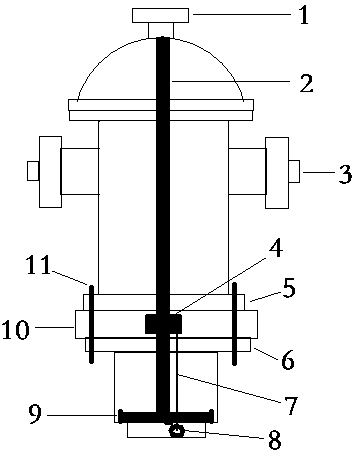

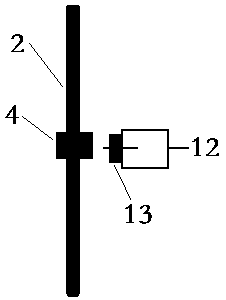

[0016] The fire hydrant state remote monitoring system of the present invention, such as figure 1 As shown, it includes an on-site detection device located on a fire hydrant and a remote monitoring center, and the on-site detection device includes a water pressure sensor, a flow sensor, an inclination sensor, an anti-pry sensor, a geographic information positioning module, and a micro-control chip circuit and wireless transmitter module. like figure 2 As shown, the water pressure sensor 8 is installed on the front end of the fire hydrant water-stop pad 9 to detect the water pressure, and is connected to the micro-control chip circuit through the wire 7 (the wire has enough length to cope with the water-stop pad being opened at will. resulting displacement). like image 3 As shown, the tamper-resistant sensor 12 is composed of a reed switch 13 and a permanent magnet 4 arranged on the fire hydrant valve stem 2 for cooperating with the reed switch 13. After the action of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com